Single-well split-type heating multifunctional storage tank device

A multi-functional, storage tank technology, applied in tank trucks, packaging, transportation and packaging, etc., can solve the problems of unclean gas, hidden safety hazards, and hidden safety hazards in tank cleaning, and achieve easy processing and production, eliminate safety hazards, and avoid safety hazards. hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

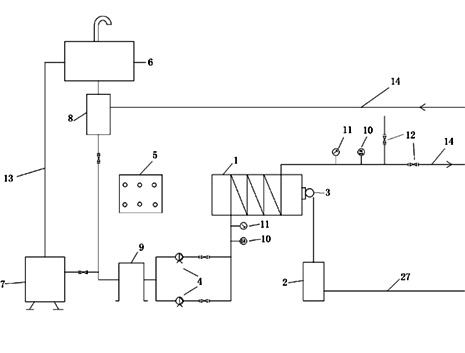

[0021] combined with Figure 1-6 , to further describe the present invention:

[0022] The present invention mainly consists of a heating furnace 1, a condenser 2, a burner 3, a hot oil circulation pump 4, an electric control cabinet 5, an expansion tank 6, an oil storage tank 7, an oil-gas separator 8, a filter 9, a thermometer 10, and a pressure gauge 11. The high-temperature gate valve 12, the medium overflow pipe 13, and the medium circulation pipe 14 form a heating furnace unit. Among them, the outlet of the heating coil in the furnace body of heating furnace 1 is a double flow, one is connected to the heat exchange coil in the storage tank through the high temperature gate valve 12, and the other is connected to the wellbore lifting heating circulation system through the high temperature gate valve 12 to provide heat source for it , The heat transfer medium in the heating coil is heat transfer oil.

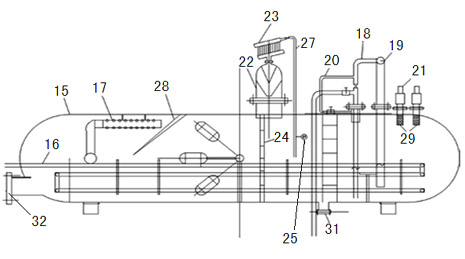

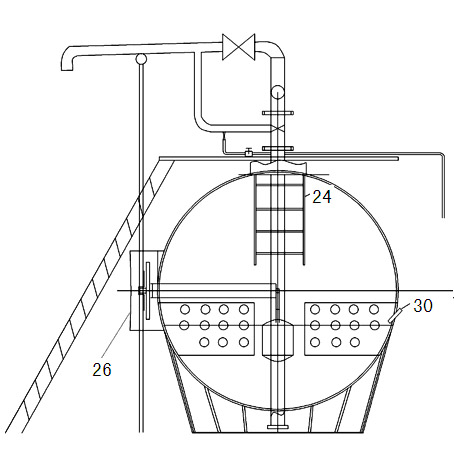

[0023] The storage tank unit is mainly composed of a horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com