Gasification burner for producing synthetic gas through gasifying fuel slurry

A technology of fuel gasification and synthesis gas, applied in the direction of granular/powder fuel gasification, joint combustion mitigation, inorganic chemistry, etc., can solve the problem of poor cooling effect of burner head, poor atomization effect of gasification burner, etc. problems, to achieve the effect of improving carbon conversion rate and effective gas yield, strengthening atomization effect, and promoting heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

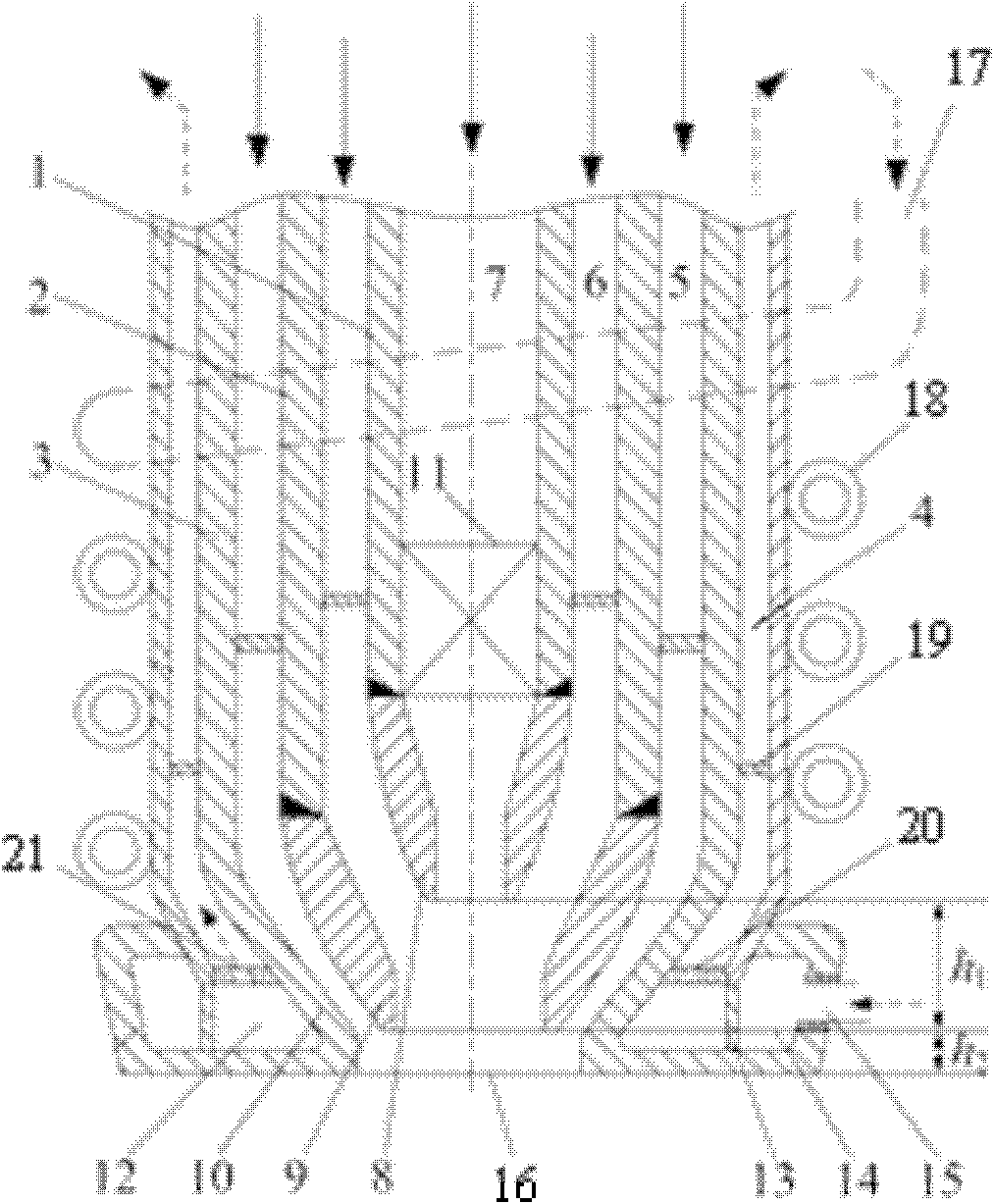

[0034] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

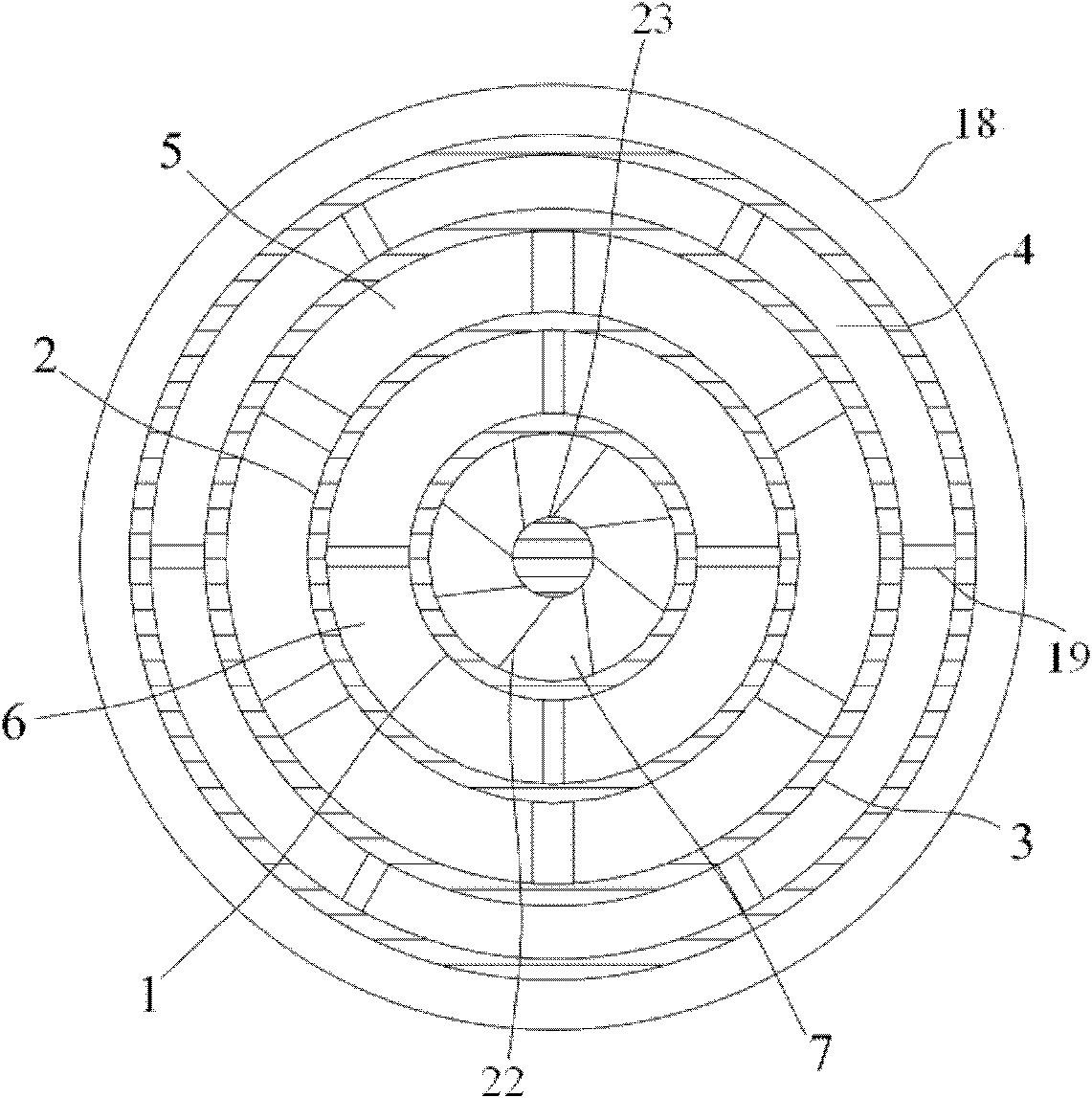

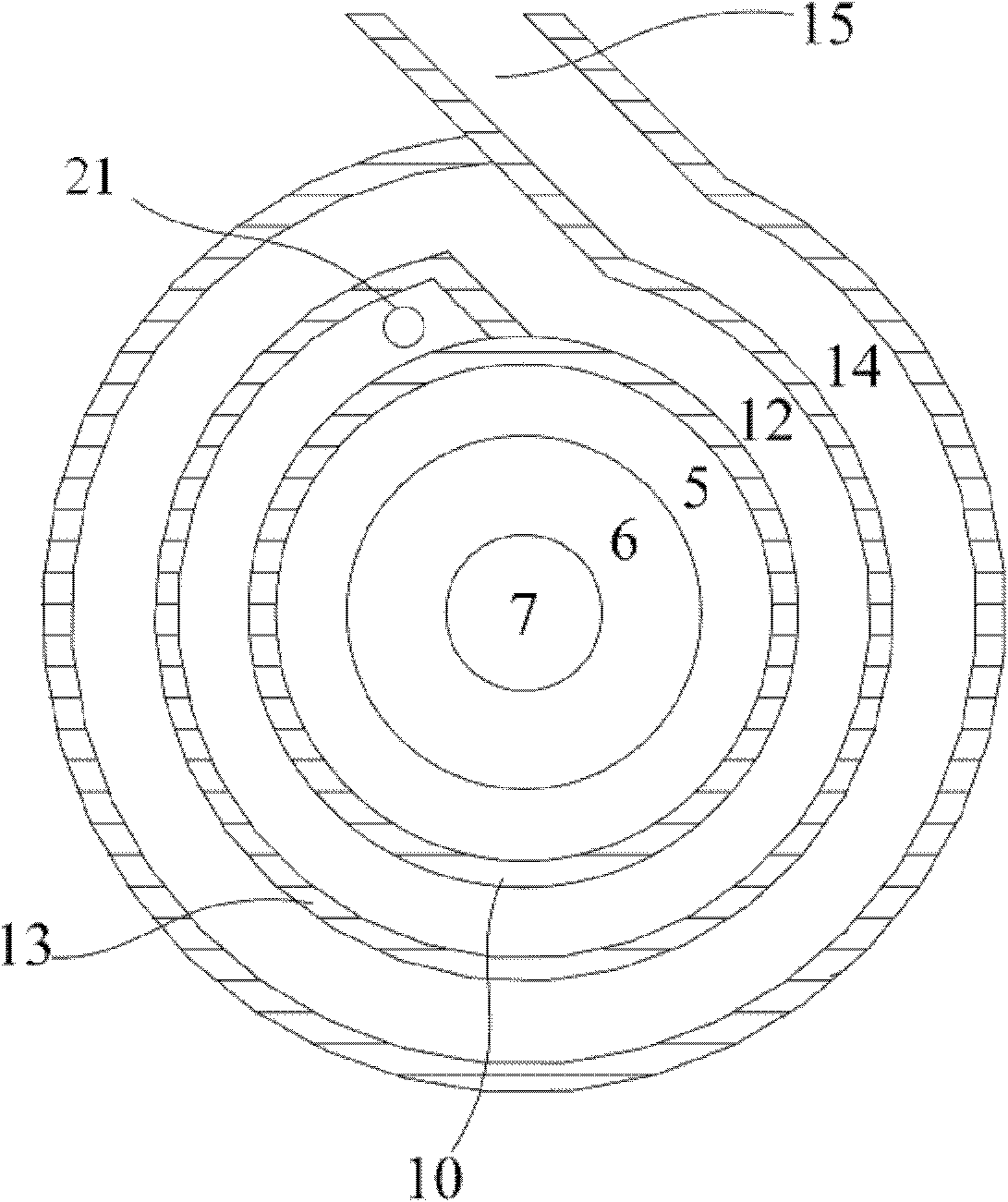

[0035] Such as figure 1 , figure 2 and image 3As shown, the gasification burner used in the gasification of slurry fuel gasification to produce syngas according to the present invention includes a three-channel main body and a cooling system. Wherein, the three-channel main body sequentially includes a central channel 7 formed by a central nozzle 1, a middle channel 6 formed by a middle ring nozzle 2 and an outer ring channel formed by an outer ring nozzle 3 from inside to outside. 5. Preferably, several fixing flanges 19 are provided in the middle ring channel 6 and the outer ring channel 5 to ensure that the channels are in a coaxial state.

[0036] The center nozzle 1, the middle nozzle 2 and the outer nozzle 3 respectively include a center nozzle 8, a middle nozzle 9 and an out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com