Method for producing ammonium nitrate solid

A technology of ammonium nitrate and solid, which is applied in the field of nitrate, can solve the problem that the ammonium nitrate solid does not give a specific guidance plan, and achieve the effects of increasing investment in fixed assets, improving product quality, and reducing reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

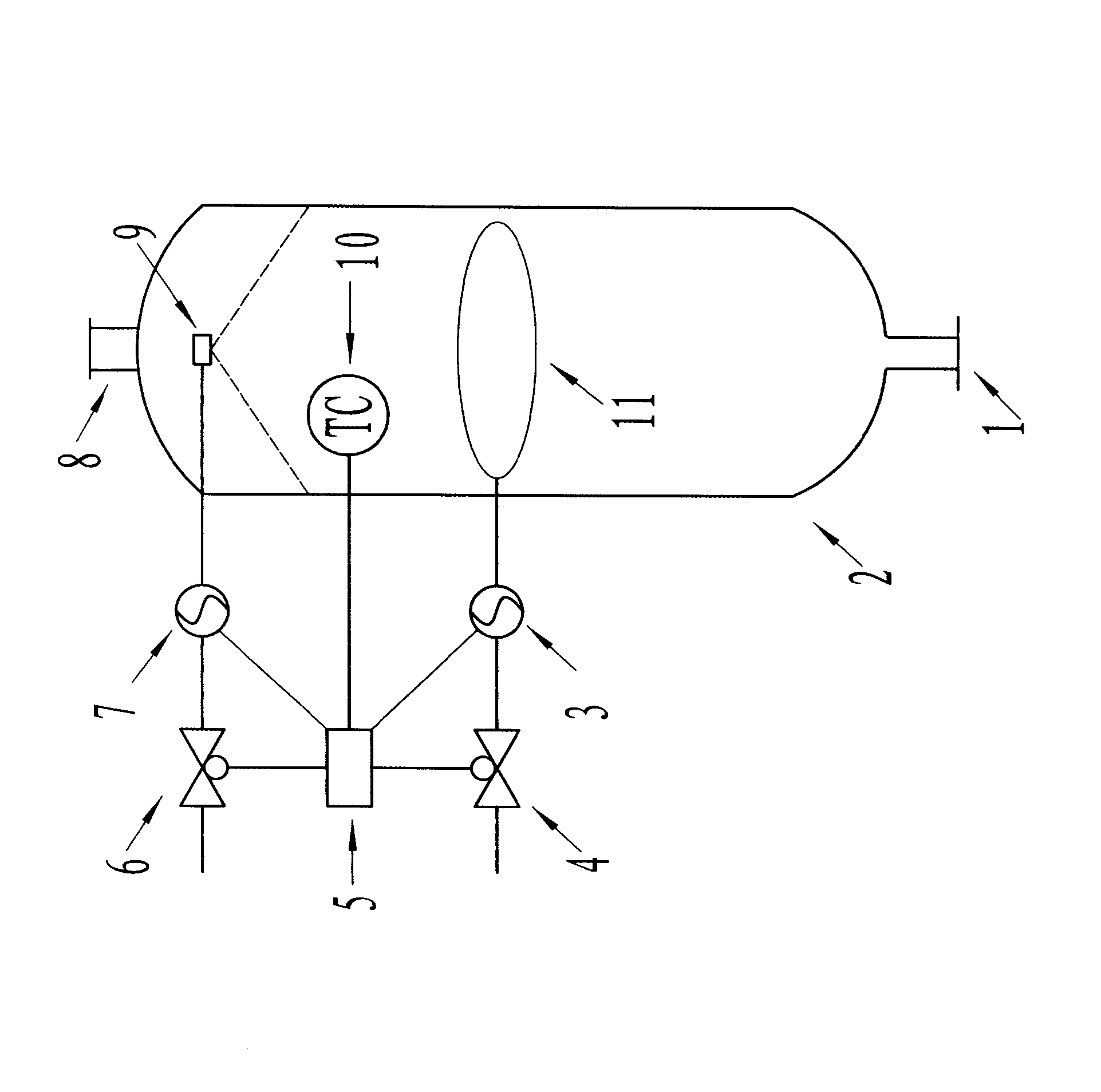

[0009] Embodiment 1: refer to figure 1 In the reaction tower of the tower reactor 2, a spray device 9 is installed at the top position, and an annular distributor 11 is installed at the middle position in the reaction tower. The annular distributor is an annular pipeline (transmitting ammonia), and the annular pipeline is There are a plurality of ventilation holes (holes through which ammonia gas passes) evenly distributed in the circumferential direction. The bottom of the reaction tower has a discharge hole 1 , and the top of the reaction tower has a top channel 8 . The tower reactor is a spray tower reactor, and its structure itself is a prior art.

[0010] The present invention makes ammonium nitrate solid by following method (reaction formula sees below):

[0011]

[0012] Pass into concentrated nitric acid and ammonia gas in the reaction tower of tower reactor, the ratio of the weight flow of concentrated nitric acid and ammonia gas is 4:1, specifically the spray de...

Embodiment 2

[0014]Embodiment 2: the present invention makes ammonium nitrate solid (reaction formula sees below) by following method: pass into concentrated nitric acid and ammonia in the reaction tower of tower reactor, the ratio of the weight flow of concentrated nitric acid and ammonia It is 5:1 or 5.2:1 or 4.7:1 or 3.7:1. Specifically, the concentrated nitric acid is passed into the spray device installed on the top of the reaction tower, and the ammonia gas is passed into the reaction from the middle of the reaction tower through the annular distributor. In the tower, adjust the spraying device so that the concentrated nitric acid is sprayed into fine concentrated nitric acid droplets on the top of the reaction tower through the spraying device. Generate fine droplets of ammonium nitrate solution, control the reaction temperature between 150~160°C, use the heat generated by the reaction to vaporize the water in the ammonium nitrate solution, complete the vapor-solid separation in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com