Pneumatic-propelling solid and liquid separation device

A solid-liquid separation, pneumatic propulsion technology, applied in the direction of dewatering/drying/concentrating sludge treatment, can solve the problems of uneven heating, difficult to heat the sludge, destroy the colloidal structure of the sludge and release water, etc., and achieve a high dehydration rate. , improve the effect of propulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

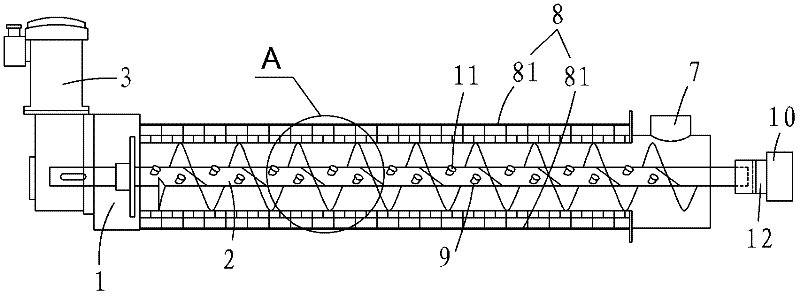

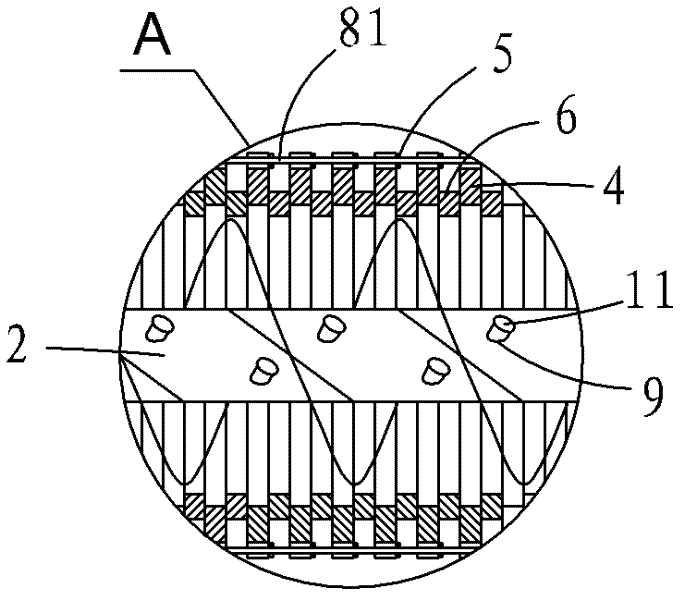

[0023] Such as figure 1 and figure 2 As shown, a pneumatic propulsion solid-liquid separation device includes a sludge discharge port 1, a screw shaft 2, a motor 3, a fixed ring 4, an adjustment block 5, a moving ring 6, a sludge inflow port 7 and a fixed bracket 8. The fixing bracket is composed of a plurality of fixing rods 81 . Such as figure 2 As shown, the spacer set ring 4 and the moving ring 6 are set on the blades of the screw shaft 2, the fixed ring is fixed by a fixed rod 81, the adjustment block 6 can be a gasket, and the adjustment block 5 makes each The distance between two adjacent fixed rings 4 is slightly larger than the thickness of the moving ring 6 , and the screw shaft 2 is driven by the motor 3 to rotate at a low speed.

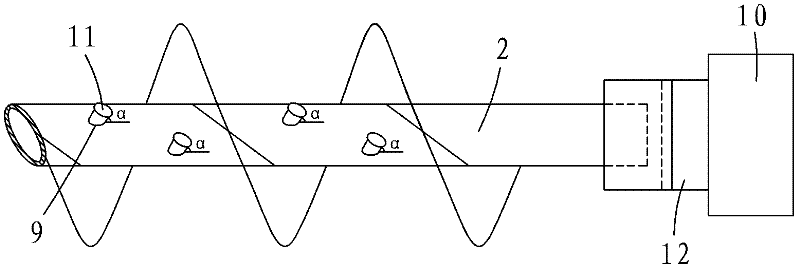

[0024] Such as image 3 As shown, a pneumatic propulsion type solid-liquid separation device, the central axis of the screw shaft 2 is hollow and a plurality of air outlets 9 are arranged on the shaft wall of the central axis of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com