Method for preparing high belite cement retarder

A technology of cement retarder and belite, which is applied in the field of preparation of high belite cement retarder, can solve the problems of poor control of cement setting time, fast setting of high belite cement, and difficulty in smooth construction operations, etc. , to achieve the effect of good thickening curve shape, wide application temperature range and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] This embodiment includes the following steps:

[0019] (1) Prepare raw materials with the following weights: 55kg of 2-acrylamide-2-methylpropanesulfonic acid, 25kg of citric acid, 15kg of sodium chromate, and 5kg of biosurfactant Tween-20;

[0020] (2) Dissolve 2-acrylamide-2-methylpropanesulfonic acid in 55kg of 30% ethanol aqueous solution at 50°C;

[0021] (3) Add citric acid first to the ethanol solution of 2-acrylamide-2-methylpropanesulfonic acid obtained in step (2), then add sodium chromate, stir evenly, and then keep warm at 75°C for 2.5 hours;

[0022] (4) Add biosurfactant Tween-20 to the solution obtained in step (3) at 40°C, stir and react at a constant temperature for 0.5 hours to obtain a high belite cement retarder.

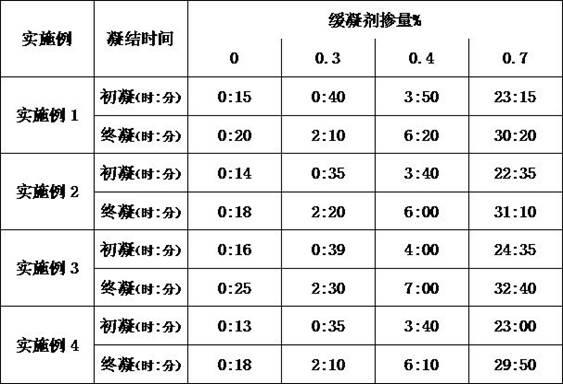

[0023] In the high belite cement, respectively mix 0% (that is, not bad), 0.3%, 0.4%, 0.7% of the high belite cement retarder prepared in this embodiment, test its setting time, the test results are shown in Table 1.

Embodiment 2

[0025] This embodiment includes the following steps:

[0026] (1) Prepare raw materials with the following weights: 40kg of 2-acrylamide-2-methylpropanesulfonic acid, 30kg of citric acid, 20kg of sodium chromate, and 10kg of biosurfactant Tween-20;

[0027] (2) Dissolve 2-acrylamide-2-methylpropanesulfonic acid in 66kg of 50% ethanol aqueous solution at 70°C;

[0028] (3) Add citric acid first to the ethanol solution of 2-acrylamide-2-methylpropanesulfonic acid obtained in step (2), then add sodium chromate, stir evenly, and then keep warm at 90°C for 2 hours;

[0029] (4) Add biosurfactant Tween-20 to the solution obtained in step (3) at 50°C, stir and react at a constant temperature for 1 hour to obtain a high belite cement retarder.

[0030] In the high belite cement, respectively mix 0% (that is, not bad), 0.3%, 0.4%, 0.7% of the high belite cement retarder prepared in this embodiment, test its setting time, the test results are shown in Table 1.

Embodiment 3

[0032] This embodiment includes the following steps:

[0033] (1) Prepare raw materials with the following weights: 60kg of 2-acrylamide-2-methylpropanesulfonic acid, 20kg of citric acid, 15kg of sodium chromate, and 5kg of biosurfactant Tween-20;

[0034] (2) Dissolve 2-acrylamide-2-methylpropanesulfonic acid in 90kg of ethanol aqueous solution with a volume concentration of 60% at 60°C;

[0035] (3) Firstly add citric acid to the ethanol solution of 2-acrylamide-2-methylpropanesulfonic acid obtained in step (2), then add sodium chromate, stir evenly, and then keep warm at 80°C for 3 hours;

[0036] (4) Add the biosurfactant Tween-20 to the solution obtained in step (3) at 60°C, stir and react at a constant temperature for 40 minutes to obtain the high belite cement retarder.

[0037] In the high belite cement, respectively mix 0% (that is, not bad), 0.3%, 0.4%, 0.7% of the high belite cement retarder prepared in this embodiment, test its setting time, the test results are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com