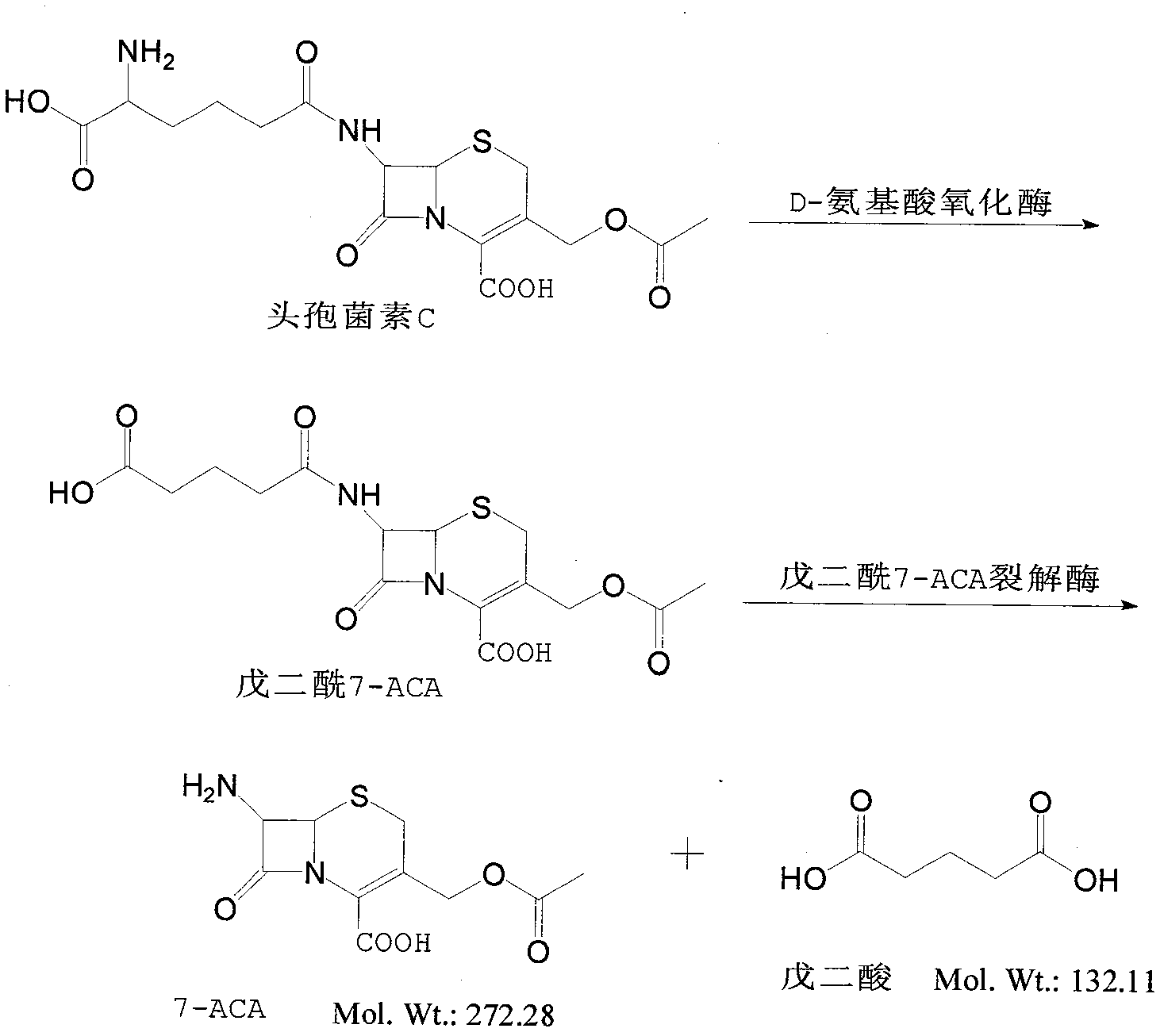

Method for recovering glutaric acid by-products produced in enzymic method prepared 7-aminocephalosporin acid process

A technology for the preparation of aminocephalosporanic acid and enzymatic method, which is applied in the field of glutaric acid by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Enzymatic preparation of 7-ACA

[0030] Convert cephalosporin C (CPC) into GL-7-ACA: use 500L jacketed pressure reactor; the reactor is equipped with marine impeller, magnetic drive, sampling and feeding port, pressure pH electrode, pressure Table, and a 100-mesh screen is installed at the bottom outlet; add 500KU immobilized D-AOD to the reactor, wash with distilled water for 1h; prepare 300L of 40g / L, pH=8.0 CPC solution, filter through 20 mesh filter and add to the reactor, then seal the top cover; then pressurize with oxygen from the bottom; pH is controlled by a pH controller, and 3mol / L NaOH is pressed in by a pump at a flow rate of 3L / min to keep pH = 8.0; the reaction solution is kept Stir at 25°C for 90min at a speed of 400r / min; take samples at 0, 10, 30, 60 and 90min, and immediately dilute with 0.2mol / L acetic acid buffer (pH3.5) for HPLC analysis; after the reaction, The solution is released from the bottom of the reactor and immediately enters ...

Embodiment 2

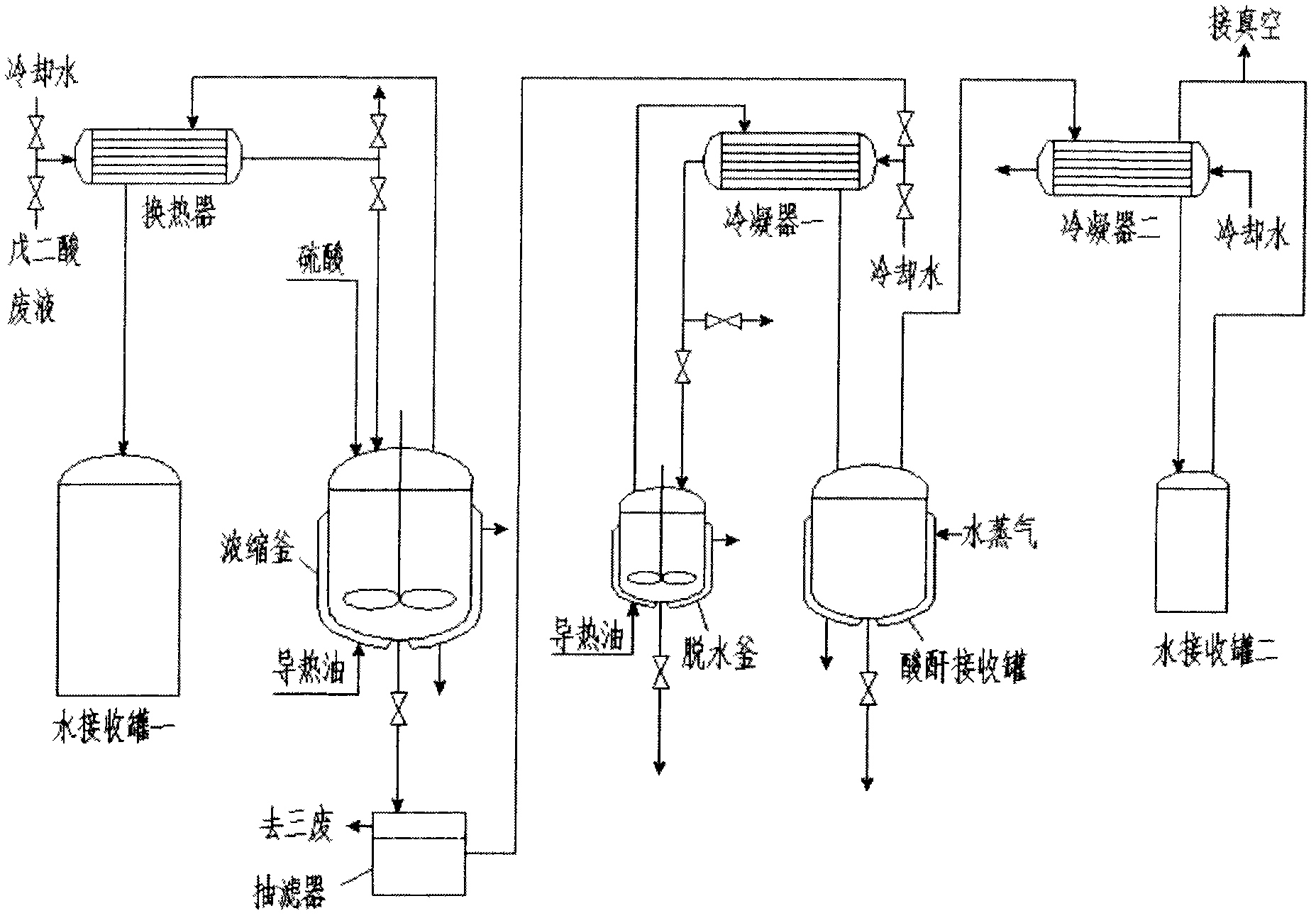

[0033] Embodiment 2: glutaric acid waste liquid is heated and concentrated

[0034] The glutaric acid waste liquid in Example 1 was preheated by a heat exchanger and then added to a concentration kettle at 120°C. The evaporated water vapor was condensed by a heat exchanger and then received by a water receiving tank; all the glutaric acid waste liquid was added to concentrate After the kettle, use cooling water to cool the water vapor, the water vapor is evaporated, and the glutaric acid waste liquid is continuously concentrated to obtain a concentrated liquid.

Embodiment 3

[0035] Embodiment 3: glutaric acid nanofiltration membrane concentration

[0036] The waste liquid containing glutaric acid produced by the enzymatic preparation of 7-ACA in Example 1 is adjusted to pH 9 with 6mol / L NaOH, and concentrated using a nanofiltration device equipped with roll-type NF-45 nanofiltration membrane element, operating pressure 0.3MPa, the control temperature does not exceed 40°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com