Method for preparing high-dielectric constant composite film of copper phthalocyanine oligomer/polymer

A technology of copper phthalocyanine oligomer chemistry and high dielectric constant, applied in the field of high dielectric constant polymer composite materials, can solve problems such as poor compatibility, poor processing reproducibility, and large dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

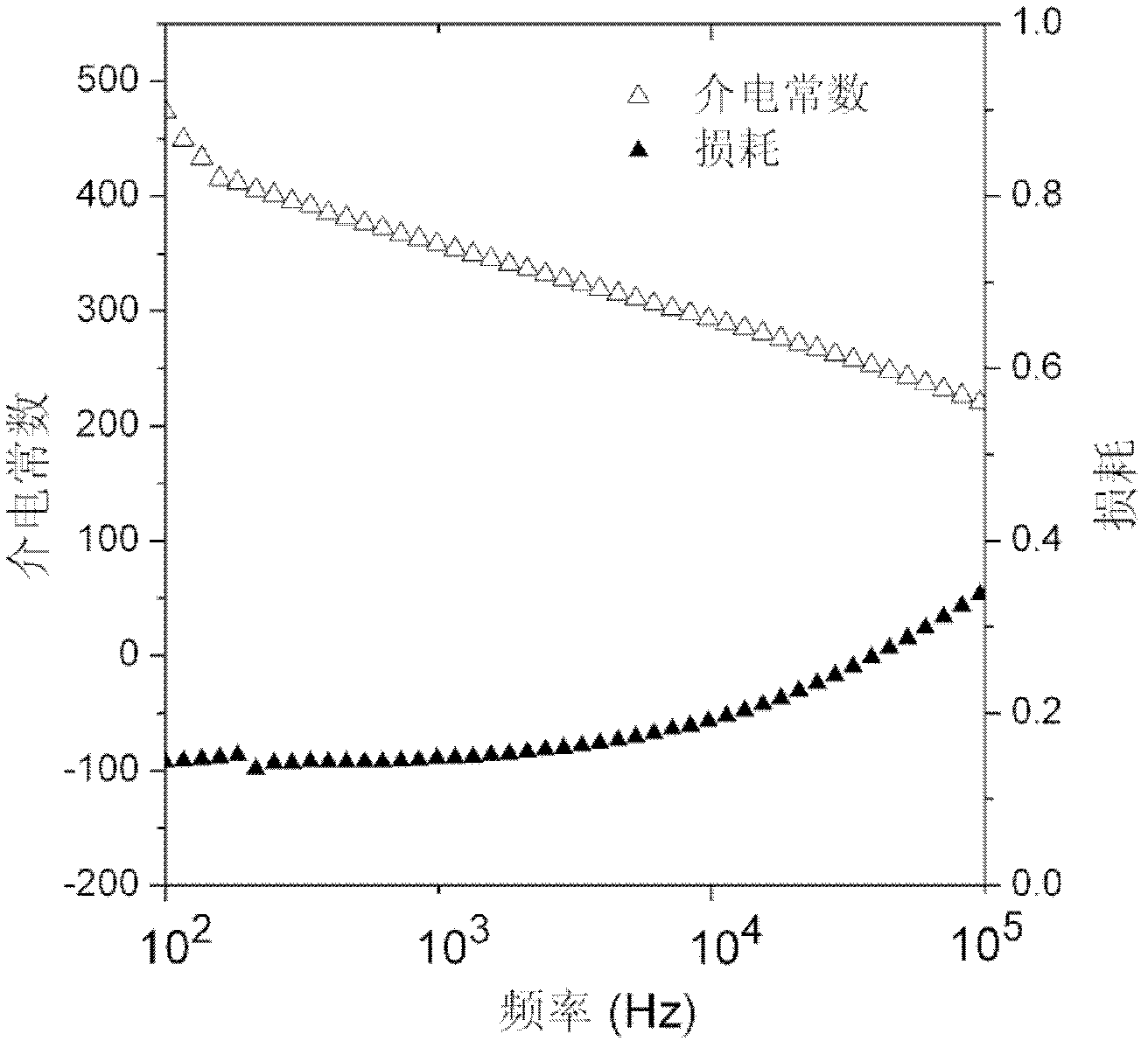

example 1

[0025] Example 1: Dissolve 1.0g of P(VDF-TrFE) in 15ml of NMP, after ozonation treatment in an oil bath at 25°C, add 0.6g of chloromethylstyrene, stir evenly, vacuumize, and blow nitrogen, at 65 °C in an oil bath for 5 hours, distilled off the solvent under reduced pressure, and dried in vacuo to obtain P(VDF-TrFE) with an active benzyl group on the molecular chain.

[0026] Dissolve 0.85g of the above-mentioned chemically modified P(VDF-TrFE) and 0.15g of copper phthalocyanine oligomer in 7.5ml of DMF, then add 0.35ml of triethylamine, protect with nitrogen, stir evenly, and react in an oil bath at 65°C After 18 hours, stop, purify, and obtain the product P(VDF-TrFE)-g-CuPc after vacuum drying;

[0027] When preparing a composite film, weigh a certain amount of P(VDF-TrFE)-g-CuPc into a small beaker containing DMF, ultrasonically disperse for 4 hours, and drop the uniformly dispersed solution on a clean glass slide to form a thin film Adhesive to glass slides. The glass sli...

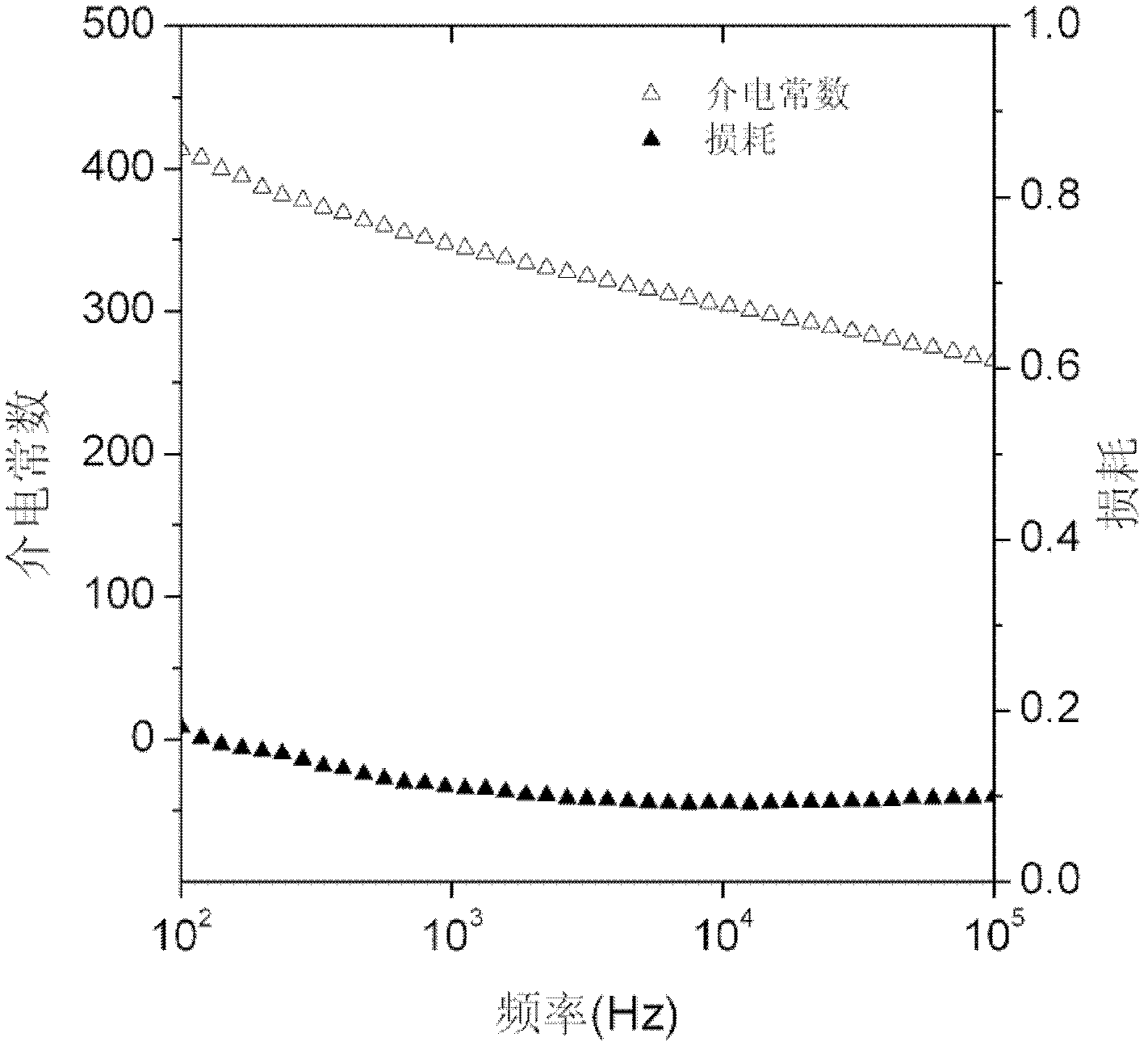

example 2

[0029] Except that the amount of P(VDF-TrFE) was 2.0 g, the grafting process was carried out in an oil bath at 50° C. for 20 hours, and the remaining contents were the same as in Example 1.

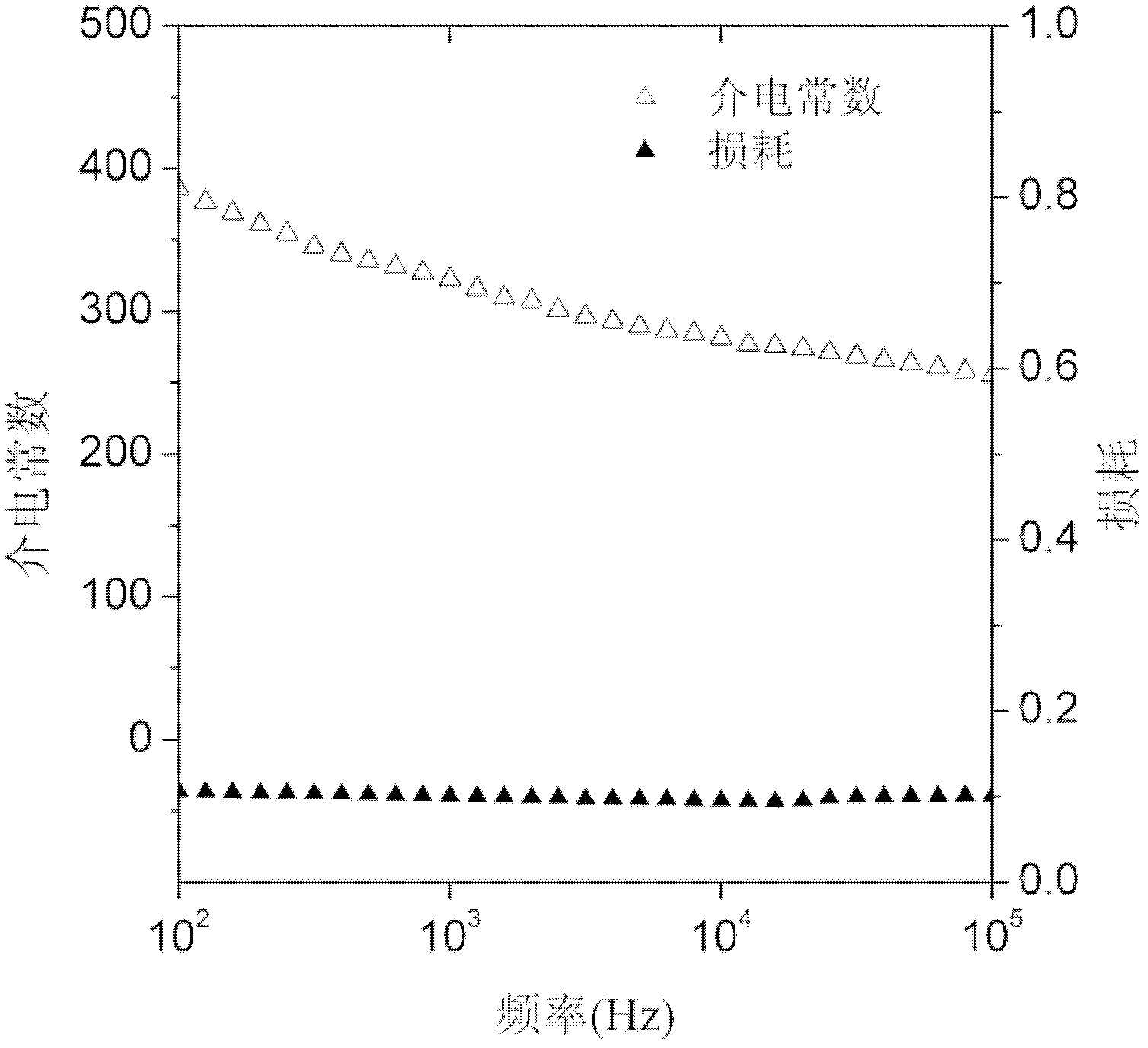

example 3

[0031]Dissolve 1.2g of P(VDF-TrFE-CFE) in 20ml of NMP, ozonize it in an oil bath at 25°C, add 0.5g of chloromethylstyrene, stir evenly, vacuumize, and protect with nitrogen. Reaction in an oil bath at ℃ for 5 hours, distillation to remove volatile matter, washing and purification, and vacuum drying to obtain P(VDF-TrFE-CFE) with an active benzyl group on the molecular chain;

[0032] Dissolve 0.85g of the above-mentioned chemically modified P(VDF-TrFE-CFE) and 0.15g of copper phthalocyanine oligomer in 7.5ml of DMF, then add 0.35ml of triethylamine, protect with nitrogen, stir mechanically, and place in a 65°C oil bath The reaction was stopped after 18 hours, purified, and vacuum-dried to obtain the product P(VDF-TrFE-CFE)-g-CuPc;

[0033] When preparing a composite film, weigh a certain amount of P(VDF-TrFE-CFE)-g-CuPc and add it to a small beaker containing DMF, ultrasonically disperse it for 4 hours, and drop the uniformly dispersed solution on a clean glass slide to make i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap