Manual-shift speed reducer of crowned-gear clutch for large-size petroleum drilling machines

A technology of gear clutches and gear shifting drums, applied in the direction of mechanical drive clutches, clutches, and clutches that mesh with each other, can solve the problems of low power, low transmission efficiency, and low reliability of the reducer, and achieve good noise shielding and safety High reliability and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

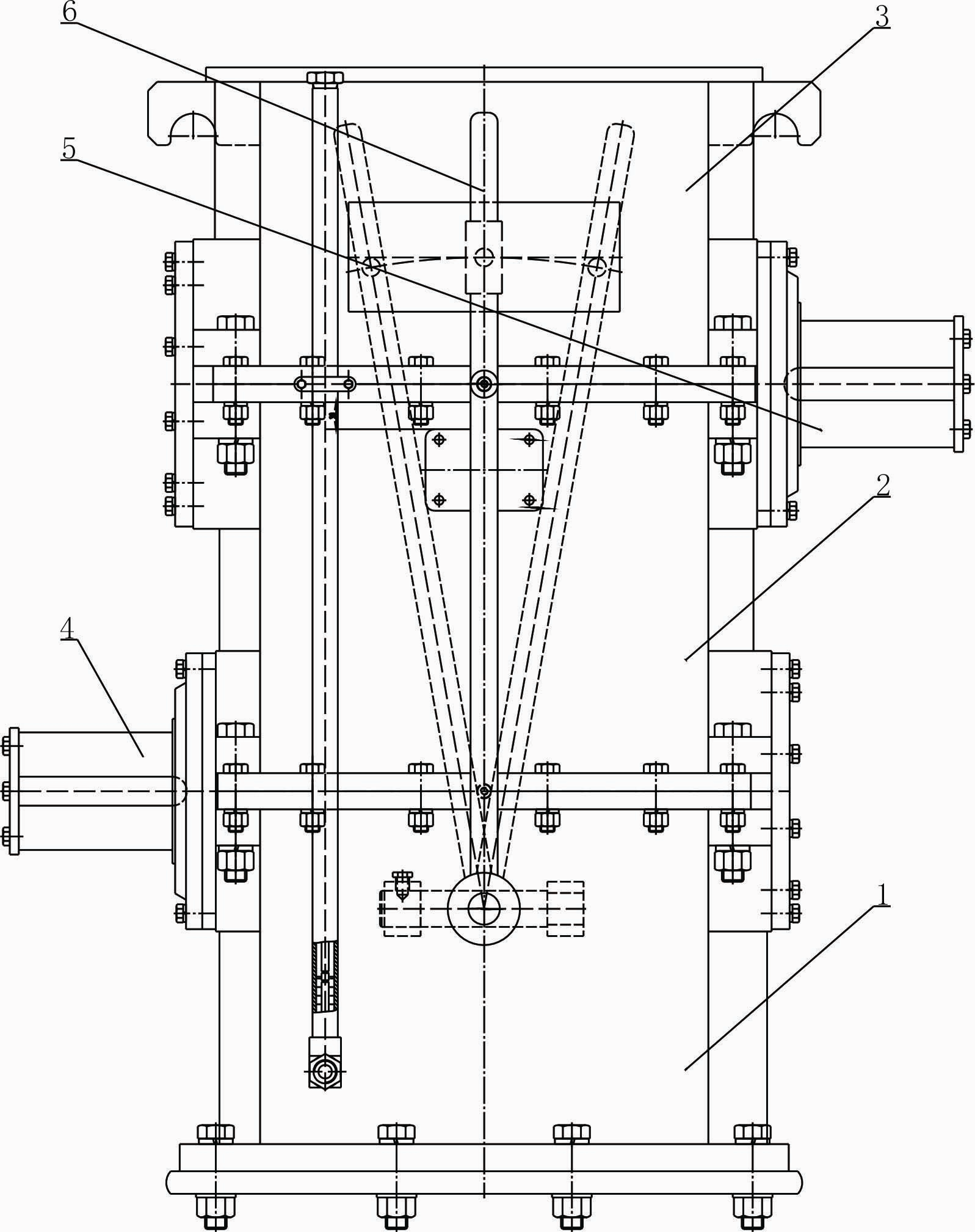

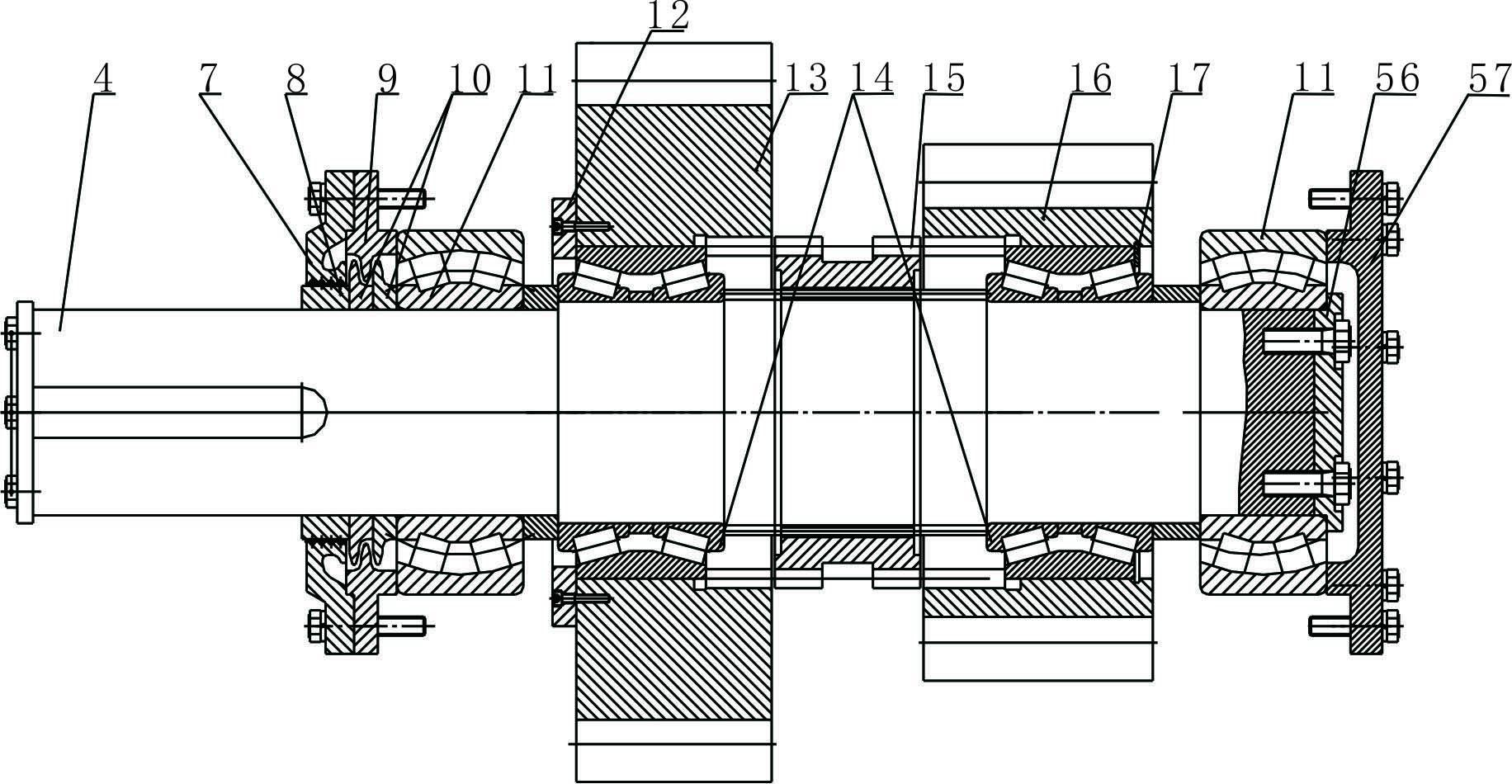

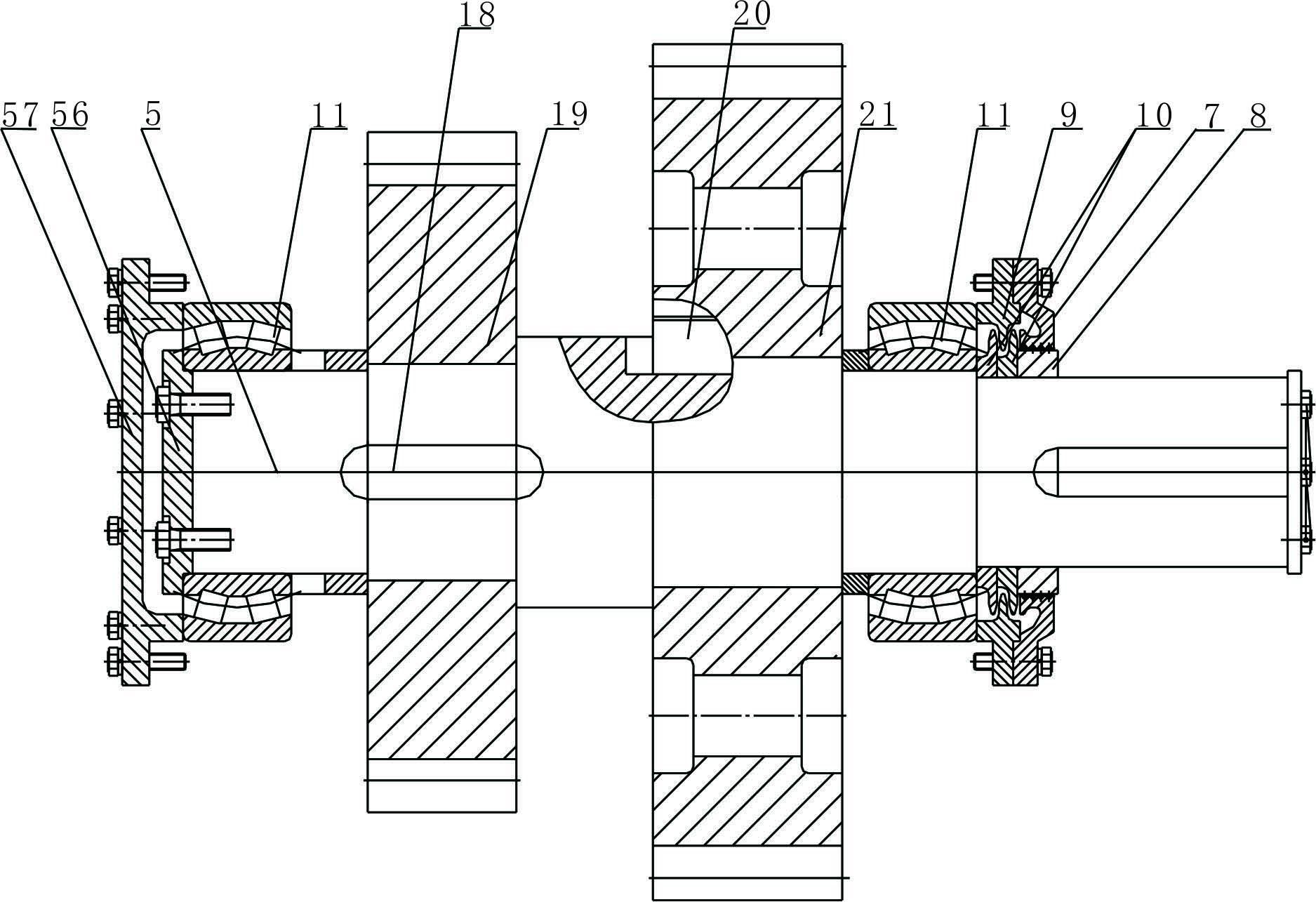

[0048] Such as figure 1 , Figure 7 and Figure 8 As shown, the large-scale oil drilling rig manually shifted drum gear clutch speed reducer provided by the present invention includes a case body assembled vertically from bottom to top by a lower case 1, a middle case 2 and an upper case 3 and The input shaft system, output shaft system, shift control mechanism, lubrication system, breather system and oil measuring rod system arranged in the box; the input shaft system is used for input power and high speed speed; the output shaft system is used for output torque and low speed Rotational speed; the shifting mechanism is used to change the transmission ratio of the input shafting and output shafting. An oil plug b46 is provided in the middle of the bottom of the lower box 1; integral lugs 54 are provided on both sides of the upper end of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com