Ice-bank refrigerating cabinet of refrigeration and purification integrated machine

An all-in-one, ice storage technology, applied in ice making, ice making, heating methods, etc., can solve the problems of non-normal use, low heat exchange efficiency of ventilation pipes, large expansion stress, etc., to improve space utilization and reduce equipment. Power consumption, effect of phase change stress relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

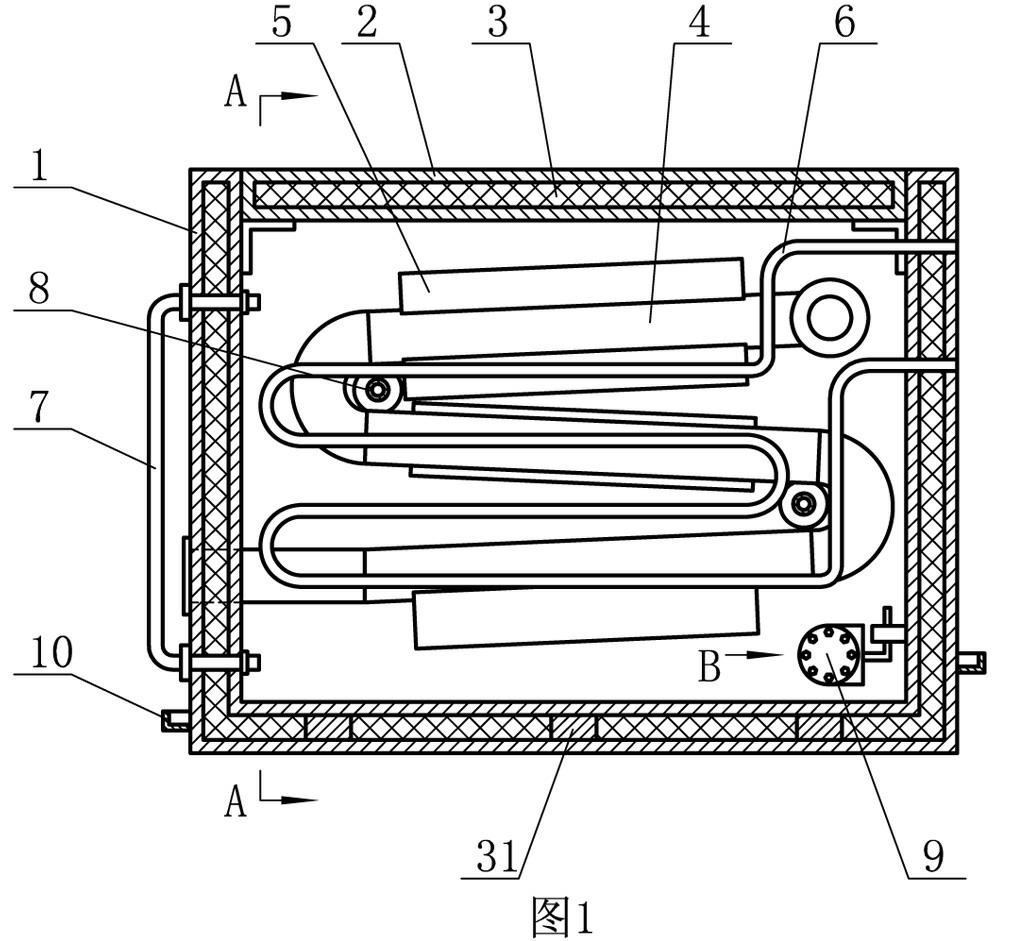

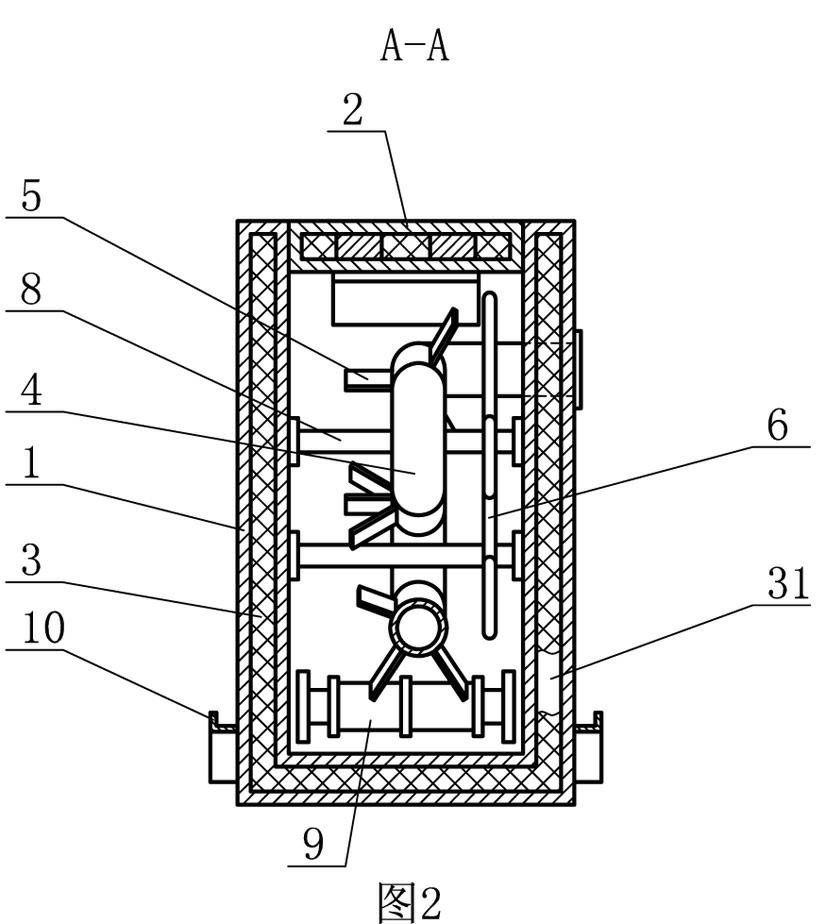

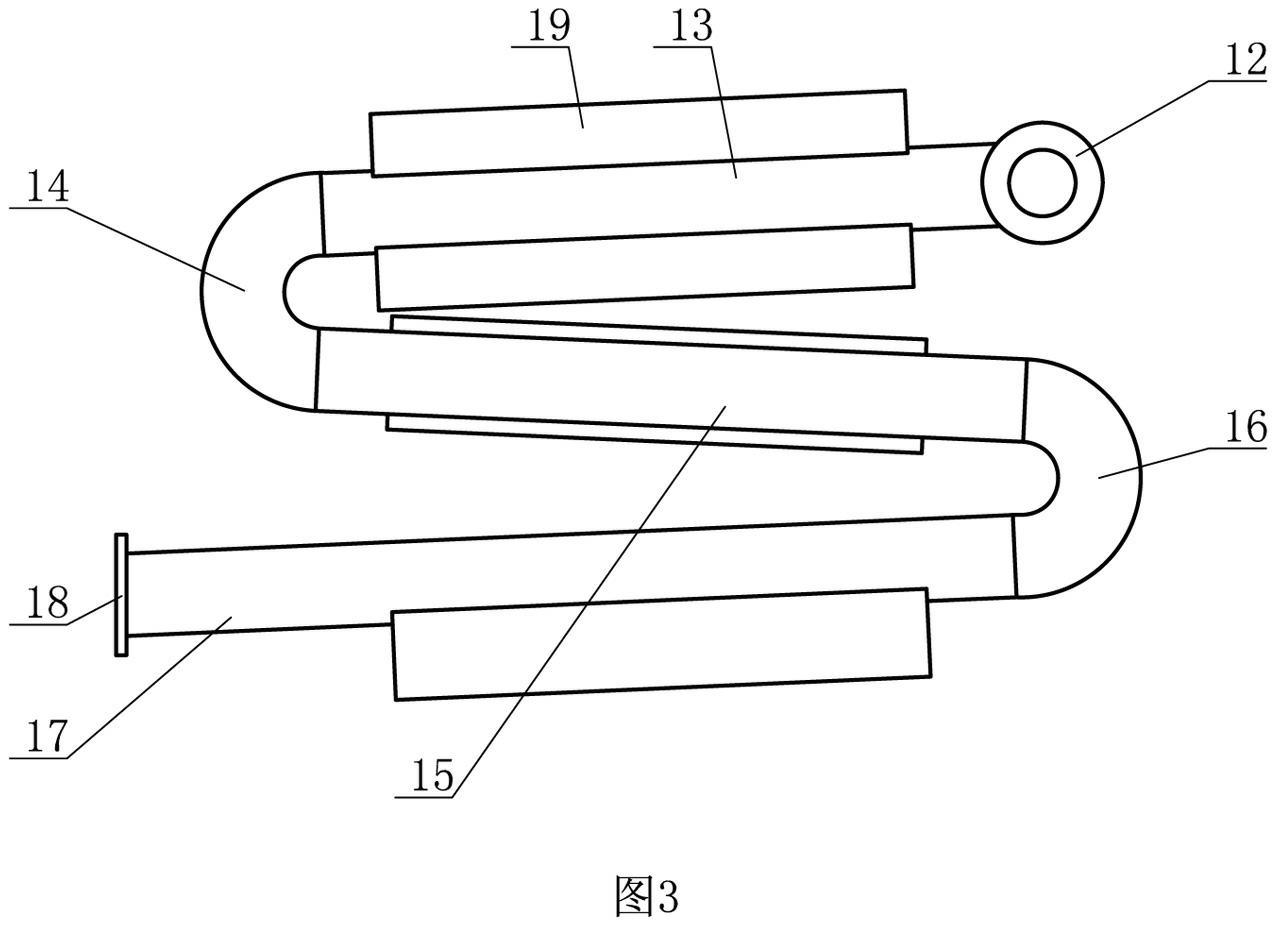

[0007] The refrigeration and purification integrated ice storage freezer of the present invention includes a cabinet body 1, a top cover 2 is provided on the top of the cabinet body 1, and the cabinet body 1 and the top cover 2 are composed of an inner shell and an outer shell. A heat insulation layer 3 is installed between the cabinet 1, a ventilation duct 4 and a condenser pipe 6 are installed in the cabinet 1, the two ends of the ventilation duct 4 are connected to the outside of the cabinet 1, the ventilation duct 4 is installed with heat exchange fins 5, and the cabinet 1 is installed on the outer wall External constant pressure pipe 7, one end of the external constant pressure pipe 7 is connected to the upper part of the cabinet 1, the other end of the external constant pressure pipe 7 is connected to the lower part of the cabinet 1, and a tie rod 8 is installed in the width direction of the cabinet 1, and both ends of the tie rod 8 are connected to the cabinet The inner w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com