Infrared laser measurement image surface alignment device

An infrared laser and alignment device technology, applied in the direction of measuring devices, optical devices, optical radiation measurement, etc., can solve the problems of camera damage, cumbersome and time-consuming operation, and affect camera performance, etc., to achieve the effect of precise alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

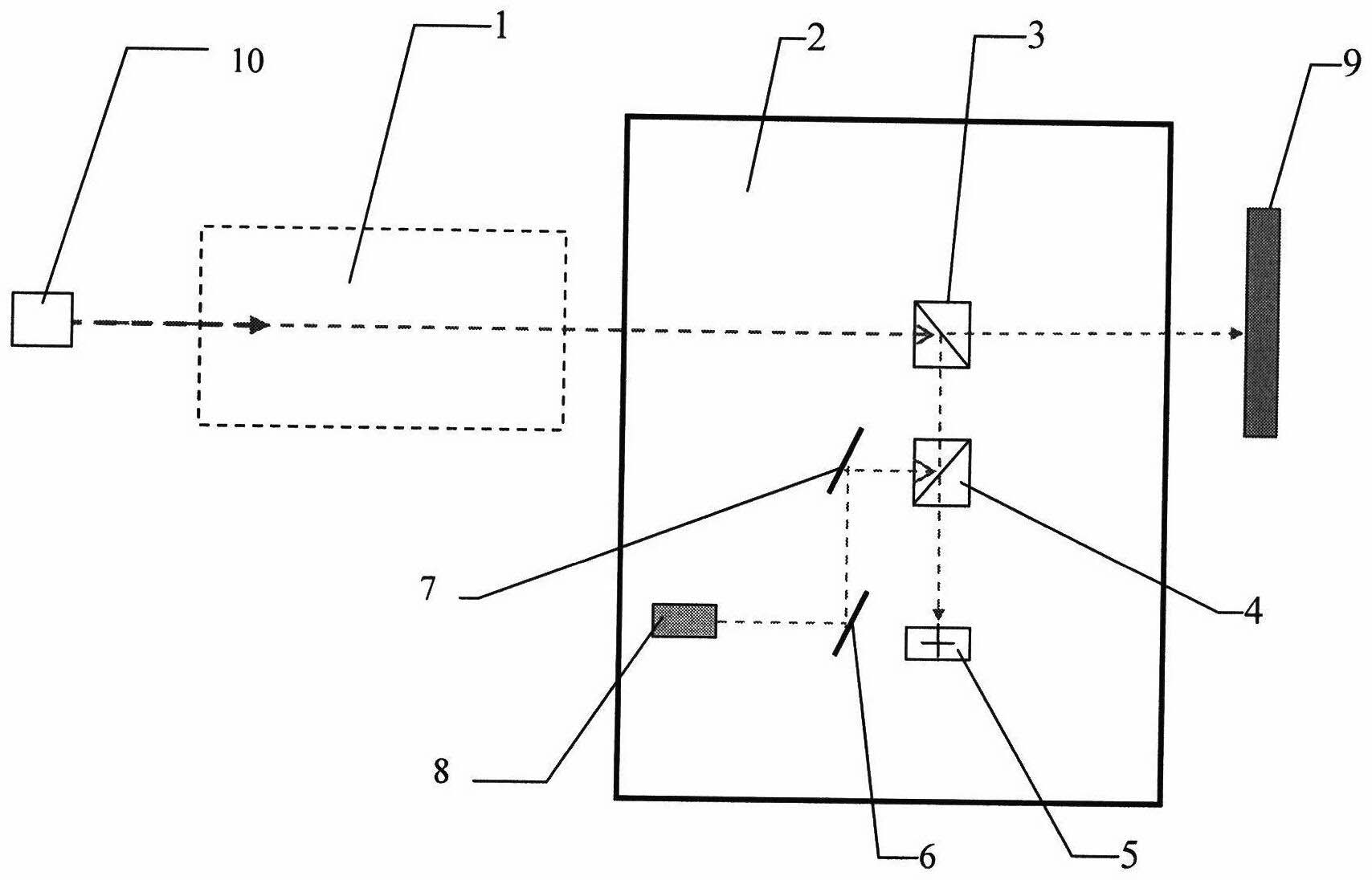

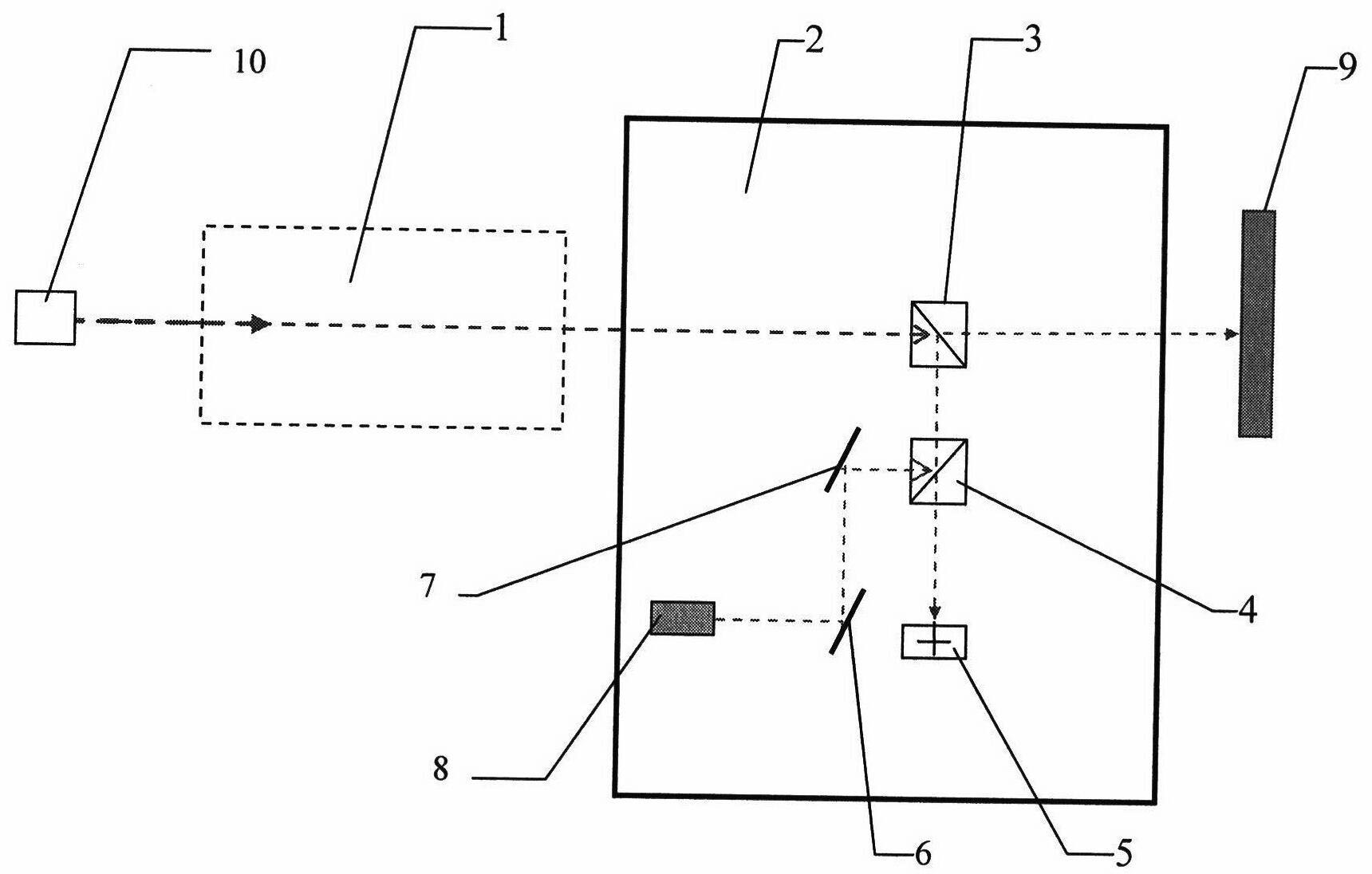

[0012] An infrared laser measurement image alignment device, such as figure 1 As shown, the device is composed of a measured laser 10, an indicating laser 8, a first reflector 6, a second reflector 7, a first dichroic prism 3, a second dichroic prism 4 and an alignment reticle 5; The measuring laser 10 is placed on the four-dimensional optical adjustment frame, which can be adjusted in height, level, pitch and azimuth; the indicating laser 8 is a green laser with a wavelength of 532nm; the first reflector 6 and the second reflector 7 are 2.54cm in diameter The plane reflectors are respectively placed on the two-dimensional optical adjustment frame, which can be adjusted in pitch and azimuth; the first beam splitting prism 3 and the second beam splitting prism 4 are right-angle beam splitting prisms which are respectively glued together by two triangular prisms, and the first beam splitting prism The beam-splitting prism 3 is used to split the incident laser light from the meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com