Two-segment type water-pressure sealed bulging piston for large-caliber collecting box

A two-stage, large-diameter technology, used in the use of liquid/vacuum for liquid tightness measurement, measurement devices, instruments, etc., it can solve micro-cracks, leave safety hazards, and take a lot of work to remove the welding and sealing plate. quantity etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

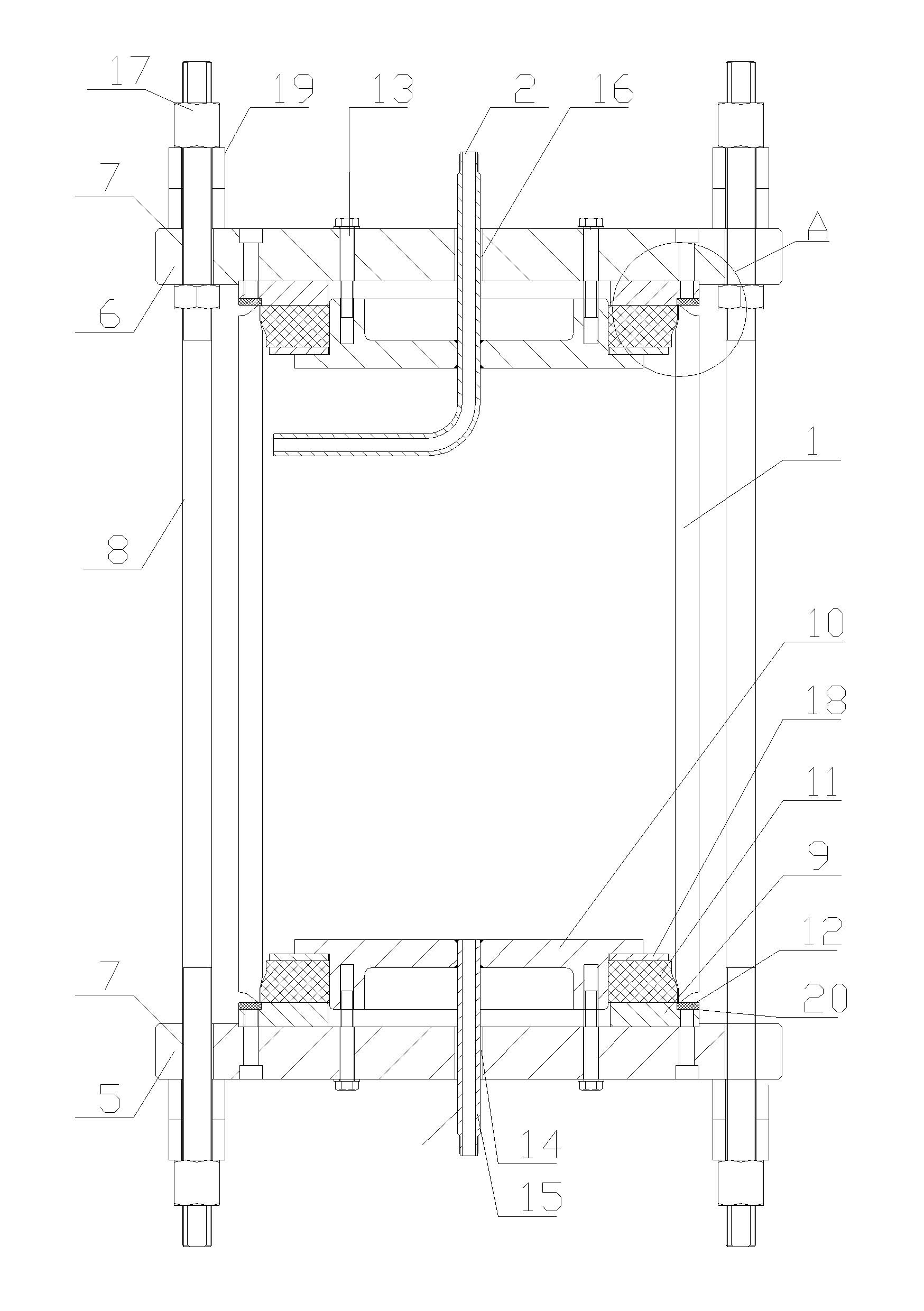

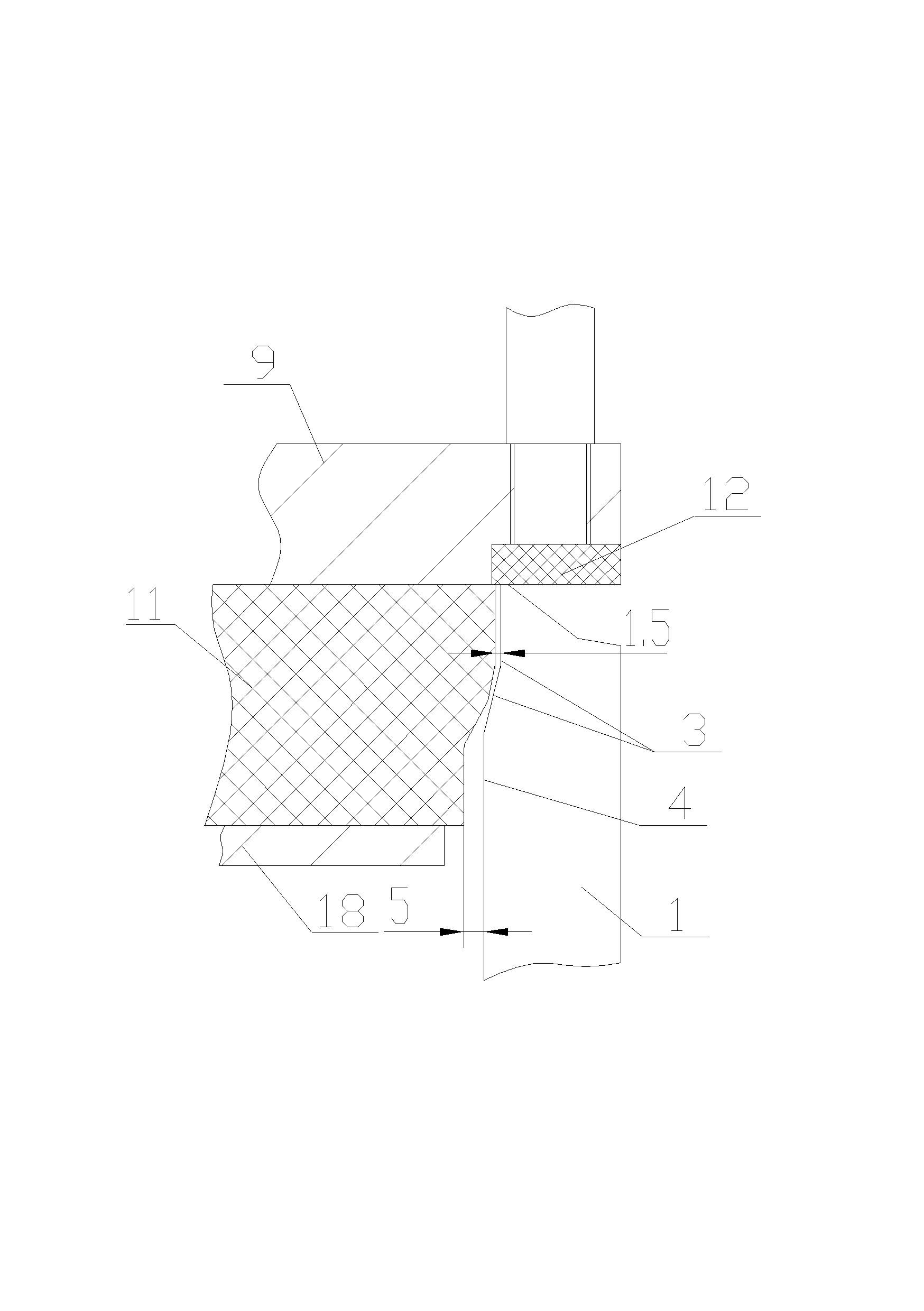

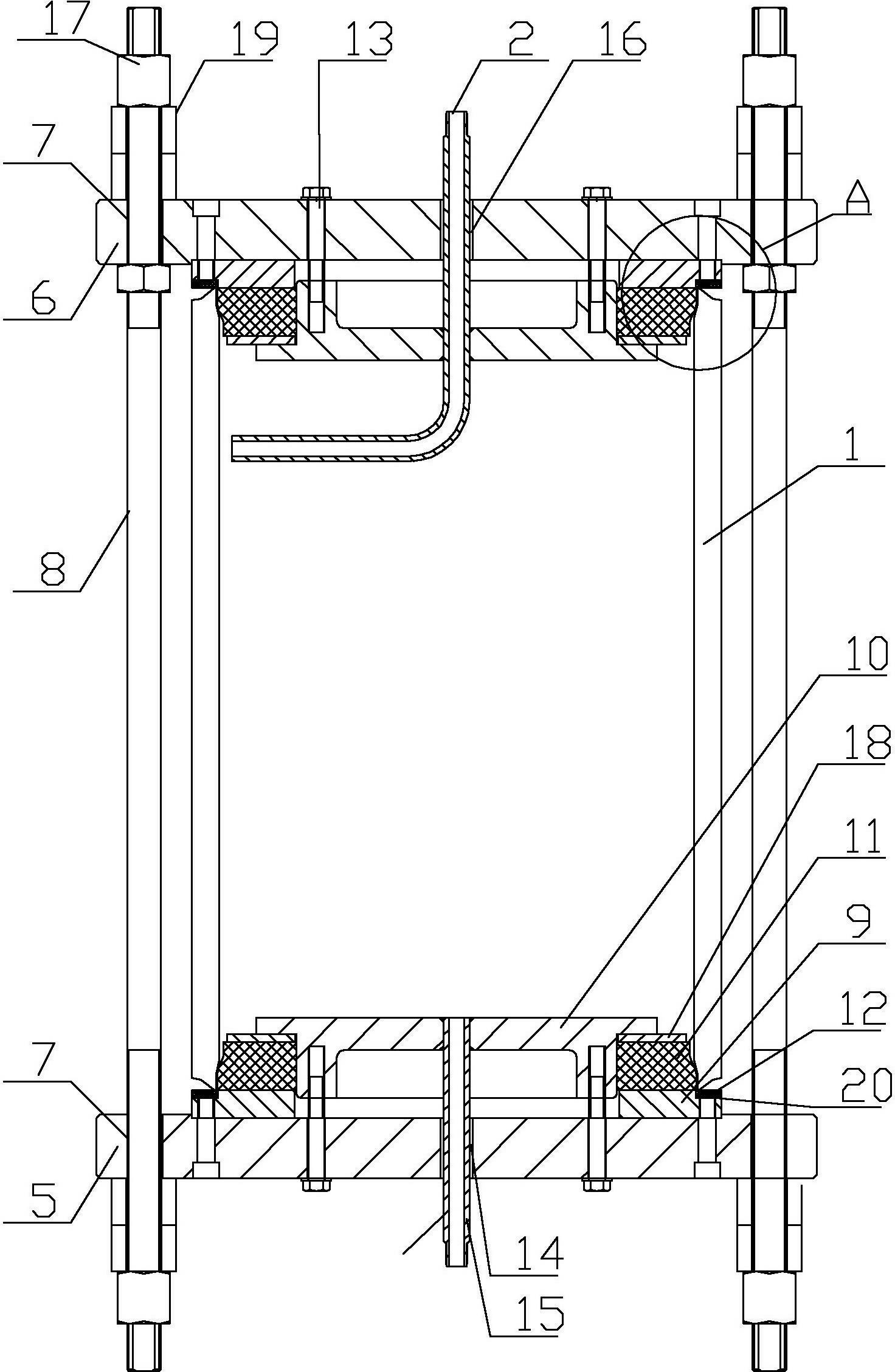

[0015] See figure 1 , figure 2 , which includes a header 1, the inner walls of the nozzles at both ends of the header 1 include a processed groove surface 3 and an internal unprocessed surface 4, two pull plates 5, 6 are respectively located at the nozzles at both ends of the header 1, two There are six guide holes 7 evenly distributed on the corresponding circumferential surfaces of the pull plates 5 and 6. The guide holes 7 are located on the outside of the header 1. The pull rods 8 run through the guide holes 7 at the corresponding positions of the two pull plates 5 and 6. The facing surfaces of the plates 5 and 6 are respectively provided with a sealing structure, the sealing structure specifically includes a guide plate 9, a pressure ring 10, a built-in seal ring 11, and an external seal ring 12, the guide plate 9 is an annular plate, and the guide plate 9 is fastened to the pulley. Plates 5 and 6, one end surface of the built-in sealing ring 11 and the outer sealing ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com