Measuring method for monitoring content of siloxane in hydrochloride during organosilicone production process

A technology for the production process of siloxane hydrochloride, which is applied in the field of determination of siloxane hydrochloride content, and achieves the effect of simple operation and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

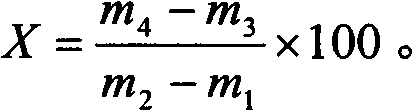

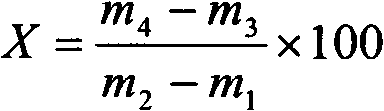

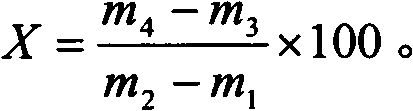

[0010] In the following examples, take a clean brown small mouth reagent bottle, weigh it, and record it as m 1 , Accurate to 0.01g; take the sample into the reagent bottle, the sampling amount is 100-1000g, record the total weight of the sample and the bottle m 2 , Accurate to 0.01g; immediately after the sample is retrieved, add 10-200ml of extractant in the fume hood, shake vigorously for 5-60min to fully wash out the oil in the acid, transfer all the liquid in the reagent bottle to the separatory funnel, Static stratification for 5-60min. Weigh the beaker with constant weight and mark it as m 3 , Accurate to 0.0001g; take out the lower oil phase of the separatory funnel into a beaker, put the oil phase in a water bath to evaporate, and transfer the beaker to the oven, and take it out at a constant temperature of 30℃-180℃ for at least 1h. Cool to room temperature in a desiccator, constant weight, mark as m 4 , Accurate to 0.0001g,

[0011] Then the siloxane content X in hydroc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com