Chip type electronic element appearance inspection machine

A technology of electronic components and inspection machines, which is applied in the direction of optical testing of defects/defects, sorting, etc., can solve problems such as high price, low efficiency, and complex structure, and achieve high production efficiency, high efficiency, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

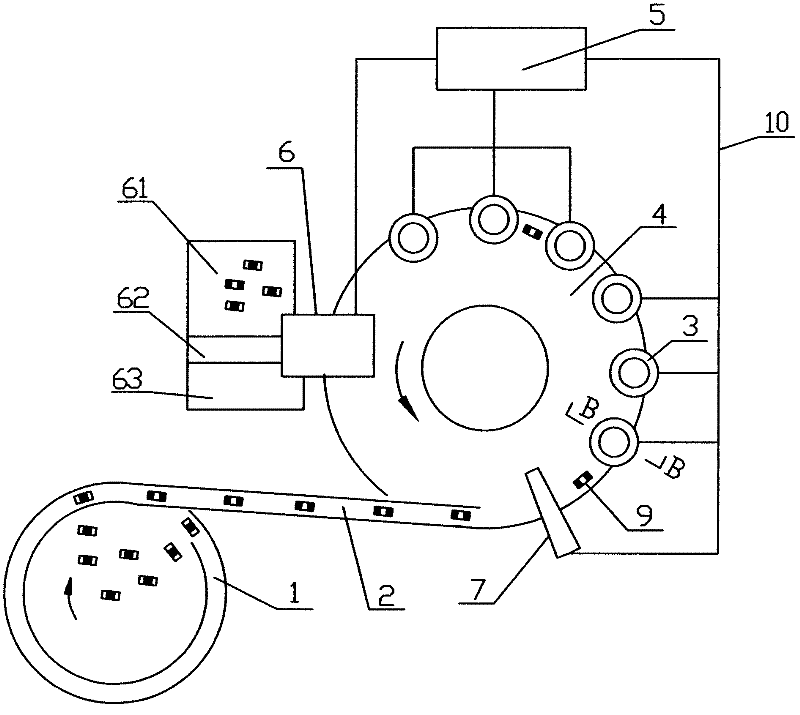

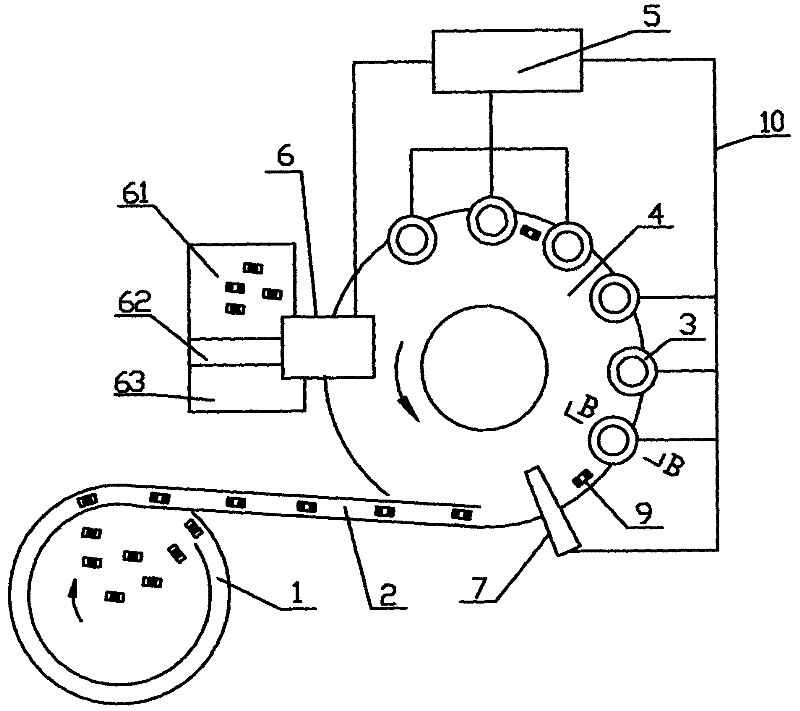

[0024] figure 1 It is a schematic diagram of a chip electronic component appearance inspection machine of the present invention, including a feeding mechanism, a transparent turntable conveying mechanism, a detection mechanism, a sorting mechanism and a control system, and the detection mechanism includes a position detection unit, a CCD camera unit, and an LED lighting unit , A focus adjustment unit; the feeding mechanism is composed of a disc feeder and a linear feeder; the transparent turntable conveying mechanism includes a glass disc.

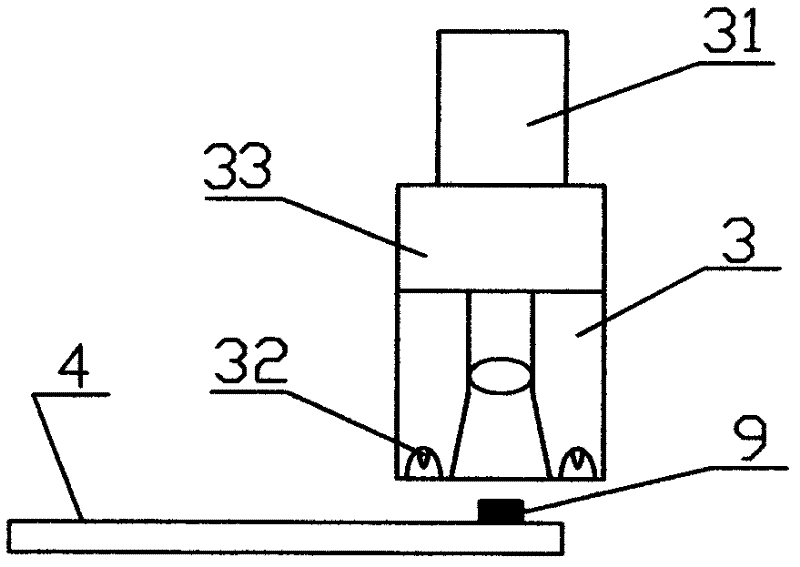

[0025] There are six CCD camera units, located on the upper, lower or edge positions of the glass disc; in the middle of each CCD camera unit, there is a focus adjustment unit; beside each CCD camera unit, there is an LED lighting unit.

[0026] The position detection unit is set on the upper position of the glass disc, and is located between the linear feeder and the CCD camera unit. When the chip electronic components arrive, the detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com