Method and equipment for calibrating dust-measuring instrument

A calibration method and dust measurement technology, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of inability to achieve continuous measurement, increase the measurement error, and large allowable error of the dust detector, and achieve true, reliable, fast and reliable measurement data. Accurate calibration, the effect of relative error reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

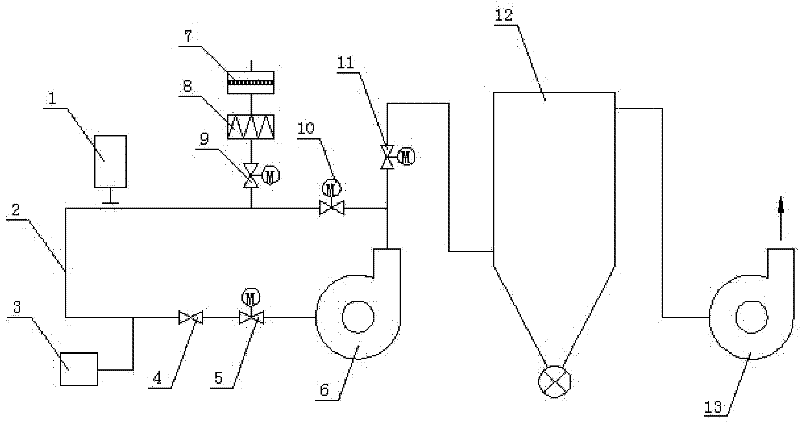

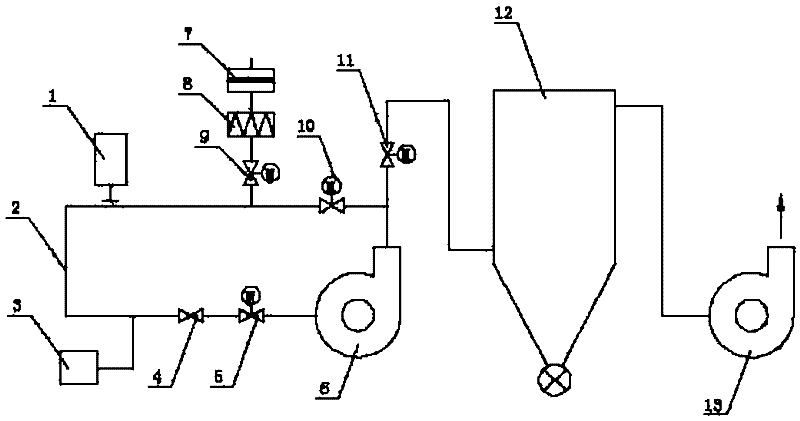

[0021] A calibration device for a dust meter, the process flow is as follows figure 1 As shown, the device includes a dust measuring instrument 1 to be calibrated, a self-circulating pipeline 2, a dust generating device 3, a flow measuring device 4, a flow rate and pressure regulating valve 5, a circulating fan 6, an air filter 7, and an air heater 8 , The first switching valve 9, the second switching valve 10 and the third switching valve 11, the dust collector 12, the exhaust fan 13 and the connecting pipes between the various devices, etc.

[0022] The outlet and the inlet of the circulating fan 6 are connected through the self-circulating pipeline 2 to realize the self-circulating flow of the gas. The dust measuring instrument 1 and the dust generating device 3 are connected to the self-circulating pipeline 2. The flow measuring device 4 and the flow rate and pressure regulating valve 5 are installed on the On the self-circulation pipeline 2, the air filter 7 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com