Method and device for testing speed of servo motor during low-speed running

A low-speed operation, servo motor technology, used in measuring devices, low-speed motor control, linear/angular velocity measurement, etc., can solve the problem of lack of motor speed information processing, inability to intuitively and easily analyze low-speed operation performance of servo motors, and inability to independently test objects, etc. problems to facilitate analysis and judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

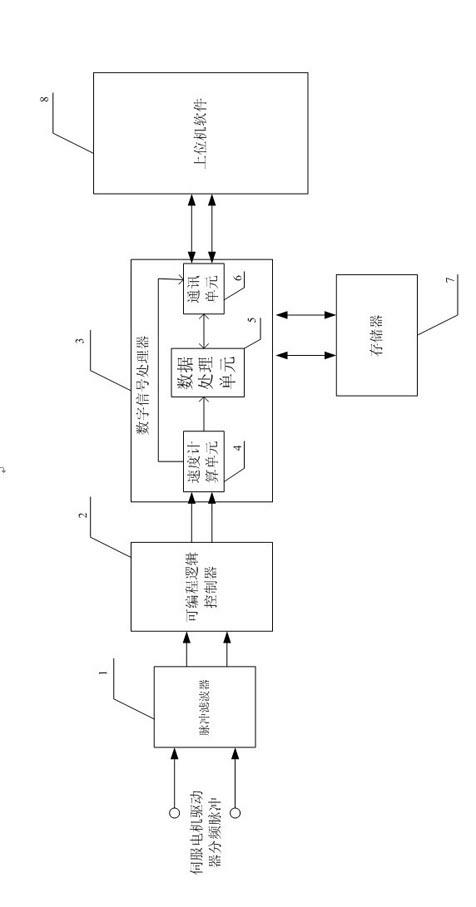

[0032] Such as figure 1 The speed measuring device shown when the servo motor is running at low speed includes a filter 1 for filtering input pulses, a programmable logic controller 2 for counting pulses and time for filtered pulses; a memory 7 for storing speed data; A digital signal processor 3 that uses the frequency cycle method to calculate and process the speed and communicates with the host computer; a host computer software that operates the speed measuring device and displays the speed data. The input terminal of filter 1 is connected to the PG frequency division pulse output of the servo driver; the output of filter 1 is connected to the input terminal of programmable logic controller 2; the programmable logic controller 2 and the digital signal processor 3 pass the data bus and address Bus connection; digital signal processor 3 and memory 7 multiplex data bus and address bus to exchange data; host computer software 8 and digital signal processor 3 are connected thro...

Embodiment 2

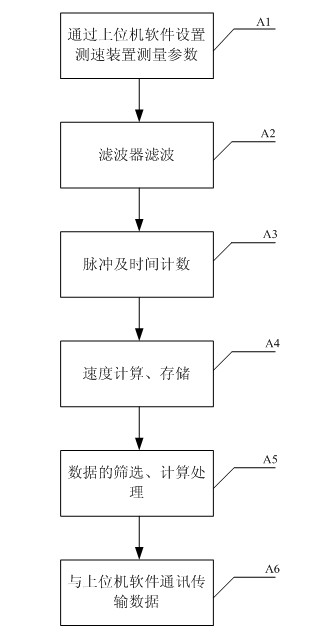

[0035] Such as figure 2 As shown, using the speed measuring device described in Embodiment 1 when the servo motor is running at low speed, the speed measuring steps for measuring the motor speed when the servo motor is running at low speed are as follows:

[0036] Step A1: The upper computer software sets the following parameters through serial port communication: data transmission rate, verification method, sampling times of each group of data, sampling interval time, number of sampling data groups, number of pulses per revolution of the motor, speed measurement resolution; sending speed measurement start instruction.

[0037] Step A2: The pulse filter performs Schmidt shaping on the PG frequency-divided quadrature pulse of the servo driver. After shaping, low-pass filtering is used to filter out high-frequency signals, and then Schmidt shaping is performed on the filtered quadrature pulse.

[0038] Step A3: The programmable logic controller performs frequency multiplicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com