Variable-diameter negative pressure type breeze speed calibration device

A calibration device and variable technology, applied in the direction of measurement device, speed/acceleration/shock measurement, test/calibration of speed/acceleration/shock measurement equipment, etc. The problem of large range and insufficient static pressure change can achieve the effect of fast measurement data, simple manufacturing process and stable airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

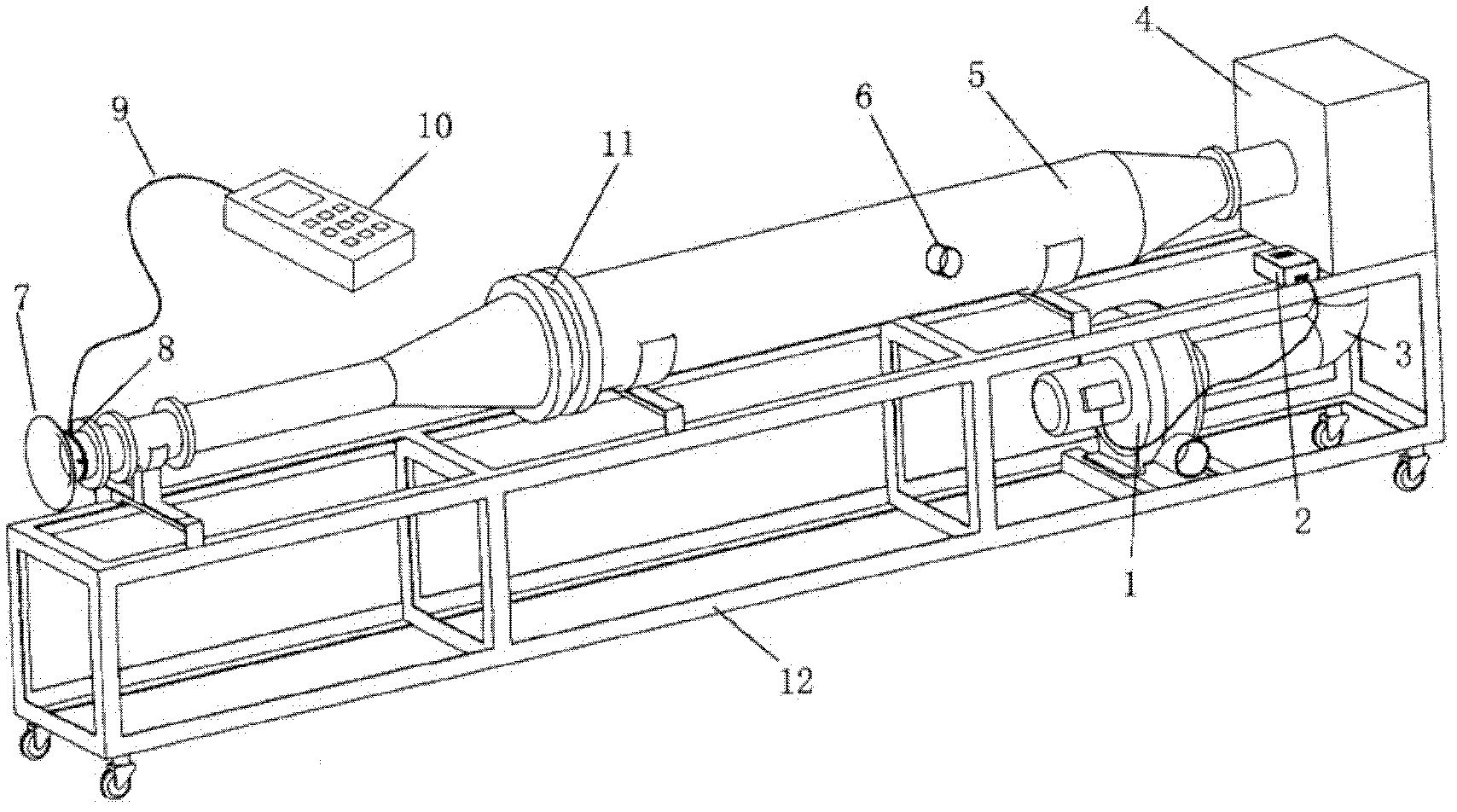

[0025] see figure 1 , the present invention discloses a variable-diameter negative pressure micro-wind speed calibration device, the device mainly includes a variable-diameter standard flow tube 7, a gradually expanding rectifying air duct 11, a standard air duct 5, a static pressure box 4, and a centrifugal fan 1. Inverter 2. Micro differential pressure gauge 10.

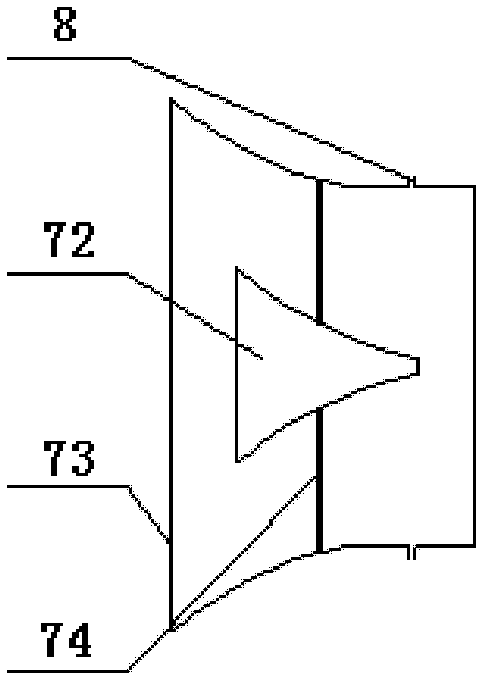

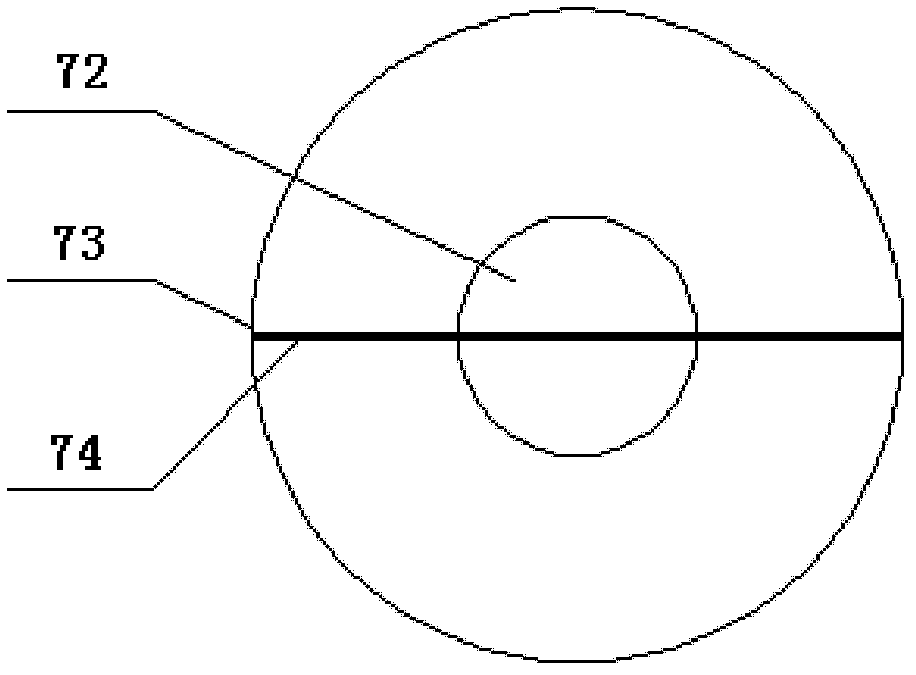

[0026] The air inlet end of the device is a variable-diameter standard flow pipe 7, which is connected with the gradually expanding rectifying air duct 11, and the gradually expanding rectifying air duct 11 is connected with the standard air duct 5, and the standard air duct 5 passes through the static pressure box 4 Flange connection, the static pressure box 4 is connected to the suction port of the centrifugal fan 1 through the hose 3, the frequency converter 2 is connected to the centrifugal fan 1 through the wire, and the variable diameter standard flow rate 7 is provided with a static pressure collection hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com