Light source packaging structure and manufacturing method thereof as well as liquid crystal display

A technology of a packaging structure and a manufacturing method, which are applied in the field of a light source packaging structure and a manufacturing method and a liquid crystal display, can solve the problems of reduced lifespan, burnt yellow, easy cracking and discoloration of epoxy resin, etc., and achieve the effect of reducing the chance of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 4 example

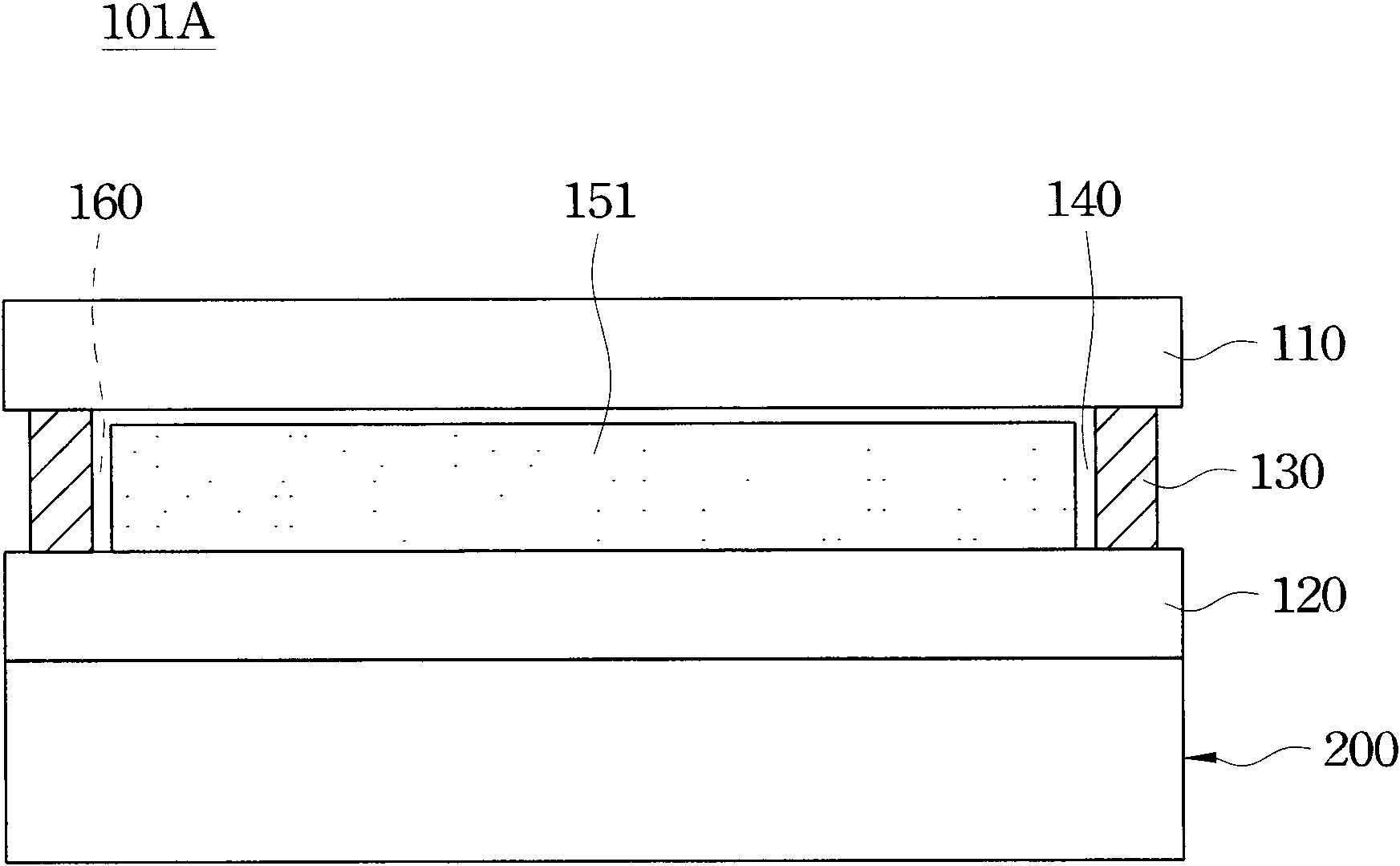

[0156] In this fourth embodiment, the liquid crystal panel 510 includes an upper substrate 511 and a liquid crystal layer 512 . The first substrate 110 of the above-mentioned light source packaging structure 100 is the lower substrate of the liquid crystal panel 510 , which means that the liquid crystal layer 512 is directly sandwiched between the upper substrate 511 of the liquid crystal panel 510 and the first substrate 110 of the light source packaging structure 100 . Therefore, on the one hand, the liquid crystal display 500 of the present invention can save the material cost of a glass substrate, and on the other hand, can reduce the distance of light traveling to the liquid crystal panel 510 .

[0157] see Figure 13A as shown, Figure 13A A schematic side view of a variation of the fourth embodiment of the liquid crystal display 500 combined with the light source packaging structure 100A of the present invention is shown.

[0158] This change is the design of the liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com