Ceramic composite materials containing carbon nanotube-infused fiber materials and methods for production thereof

A composite material, carbon nanotube technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as nanomaterials not yet contained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

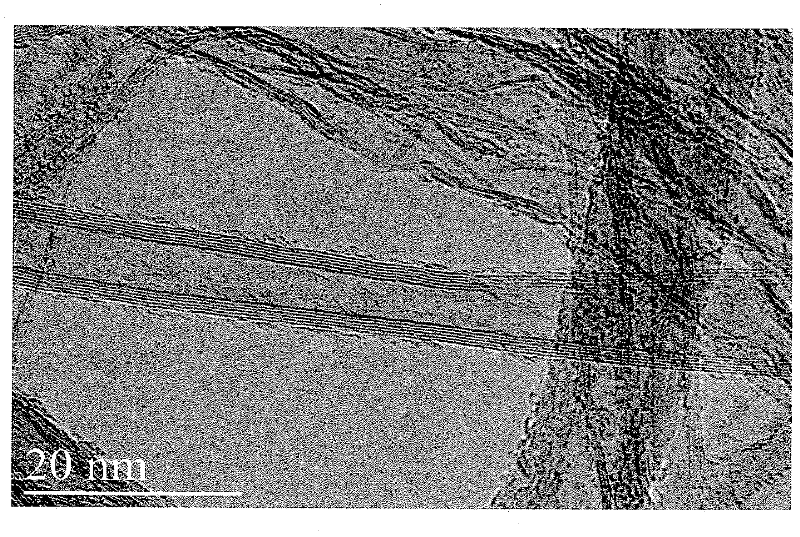

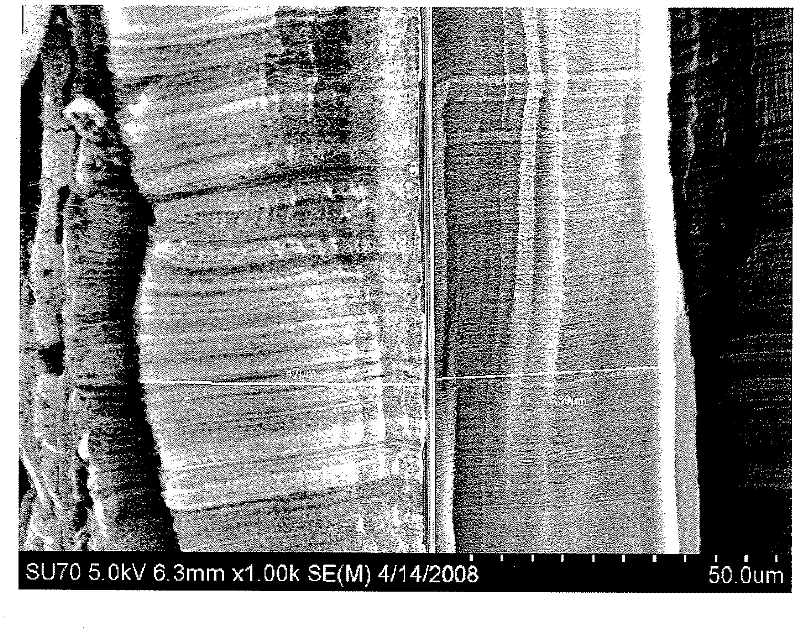

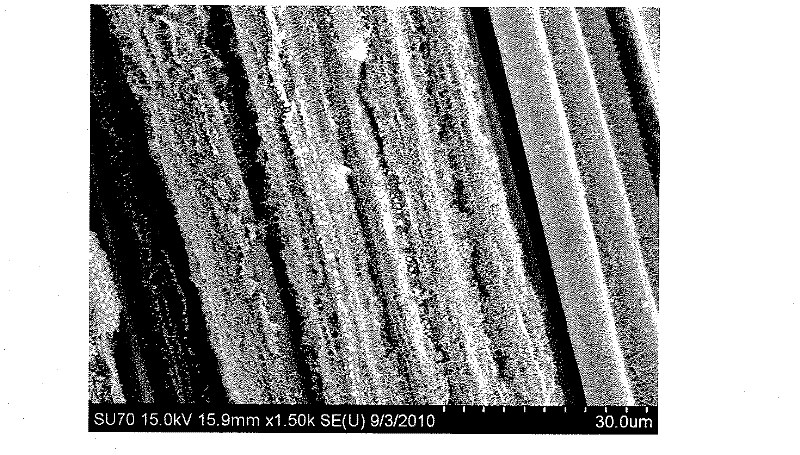

[0134] Example 1: Formation of carbon nanotube-infused carbon fiber ceramic matrix composites. Silicon carbide matrix composites were prepared by colloidal processing of chopped carbon nanotube-infused carbon fibers. Chopped carbon fibers were Grafil, Inc. (Sacramento, CA) 34-700, 12k filaments infused with carbon nanotubes with an average length of 55 μm prepared by the continuous infusion method described above. Fibers were chopped to 3mm length. By mixing a colloidal mixture of silicon carbide nanoparticles and binder (SiC nanoparticles + binder = 50% by weight) with chopped carbon nanotube-infused carbon fibers (50% by weight) , to prepare silicon carbide matrix composites. The resulting mixture of silicon carbide nanoparticles, binder, and carbon nanotube-infused carbon fibers was placed in a test brick press model. To cure the adhesive and produce green ceramic tiles, the mold containing the mixture was heated to 175° C. for 30 minutes under a pressure of 2500 psi. A...

Embodiment 2

[0135] Example 2: Formation of carbon nanotube-infused carbon fiber ceramic matrix composites. Preparation of silicon carbide matrix composites by colloidal processing of chopped carbon nanotube-infused carbon fibers. Chopped carbon fibers were Grafil, Inc. (Sacramento, CA) 34-700, 12k filaments infused with carbon nanotubes with an average length of 55 μm prepared by the continuous infusion method described above. Fibers were chopped to 3mm length. A silicon carbide matrix composite was prepared by mixing a colloidal mixture of silicon carbide nanoparticles and a binder with chopped carbon nanotube-infused carbon fibers. By mixing a colloidal mixture of silicon carbide nanoparticles and binder (SiC nanoparticles + binder = 90% by weight) with chopped carbon nanotube-infused carbon fibers (10% by weight), Preparation of silicon carbide matrix composites. The resulting mixture of silicon carbide nanoparticles, binder, and carbon nanotube-infused carbon fibers was placed in a...

Embodiment 3

[0136] Example 3: Formation of carbon nanotube-infused carbon fiber ceramic matrix composites. Preparation of silicon carbide matrix composites by colloidal processing of chopped carbon nanotube-infused carbon fibers. Chopped carbon fibers were Grafil, Inc. (Sacramento, CA) 34-700, 12k filaments infused with carbon nanotubes with an average length of 55 μm prepared by the continuous infusion method described above. Fibers were chopped to 3mm length. Prepared by mixing a colloidal mixture of silicon carbide nanoparticles and binder (SiC nanoparticles + binder = 75% by weight) with chopped carbon nanotube-infused carbon fibers (25% by weight) Silicon carbide matrix composites. The resulting mixture of silicon carbide nanoparticles, binder, and carbon nanotube-infused carbon fibers was placed in a test brick press model. To cure the adhesive and produce green ceramic tiles, the mold containing the mixture was heated to 175° C. for 30 minutes under a pressure of 2500 psi. Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com