Preparation method of tobacco sheet

A technology of tobacco sheet and cigarette sheet, which is applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problems of lack of preparation technical scheme, lack of comprehensive consideration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The tobacco stems and tobacco dust used in the experiment were provided by Guangdong China Tobacco Industry Co., Ltd., which were conventional commercially purchased tobacco stems and tobacco dust. The tobacco stems and tobacco dust were refrigerated at 4°C and packed into bags to balance the moisture for later use.

[0025] Single-stage immersion extraction: the experiment of single-stage immersion extraction of tobacco stems and tobacco dust was carried out in a digital constant temperature water bath (Jinyi HHS water bath was used in this example). First put the tobacco stems and tobacco powder into a polyethylene sealed bag, add a certain volume of distilled water, and put them into water baths that have been raised to different temperatures to keep warm. During the immersion extraction, rub it every 10 minutes to make the reaction even. After the single-stage immersion extraction is completed, it is squeezed and dehydrated in a 120-mesh polyester net, and the extra...

Embodiment 2

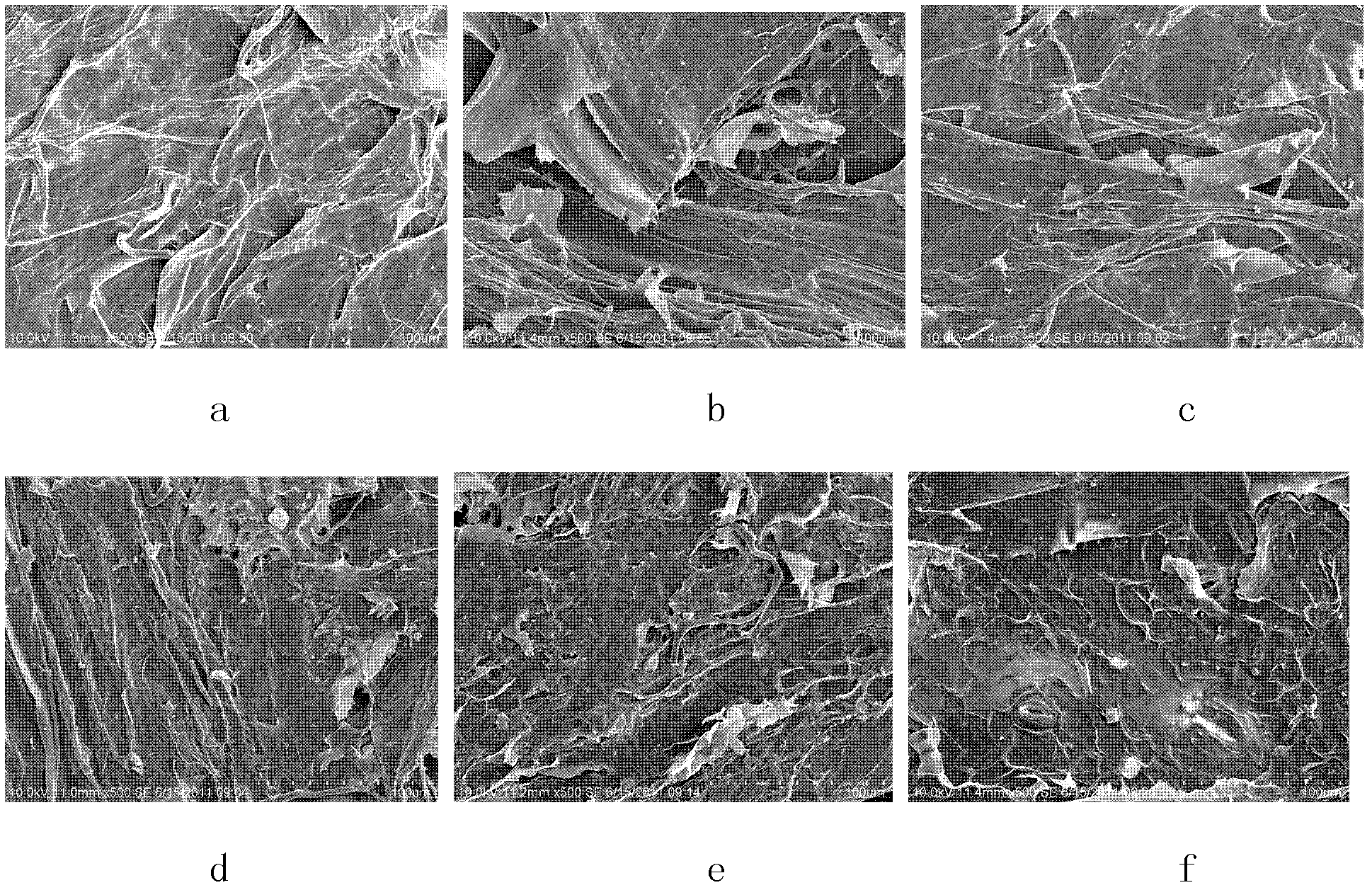

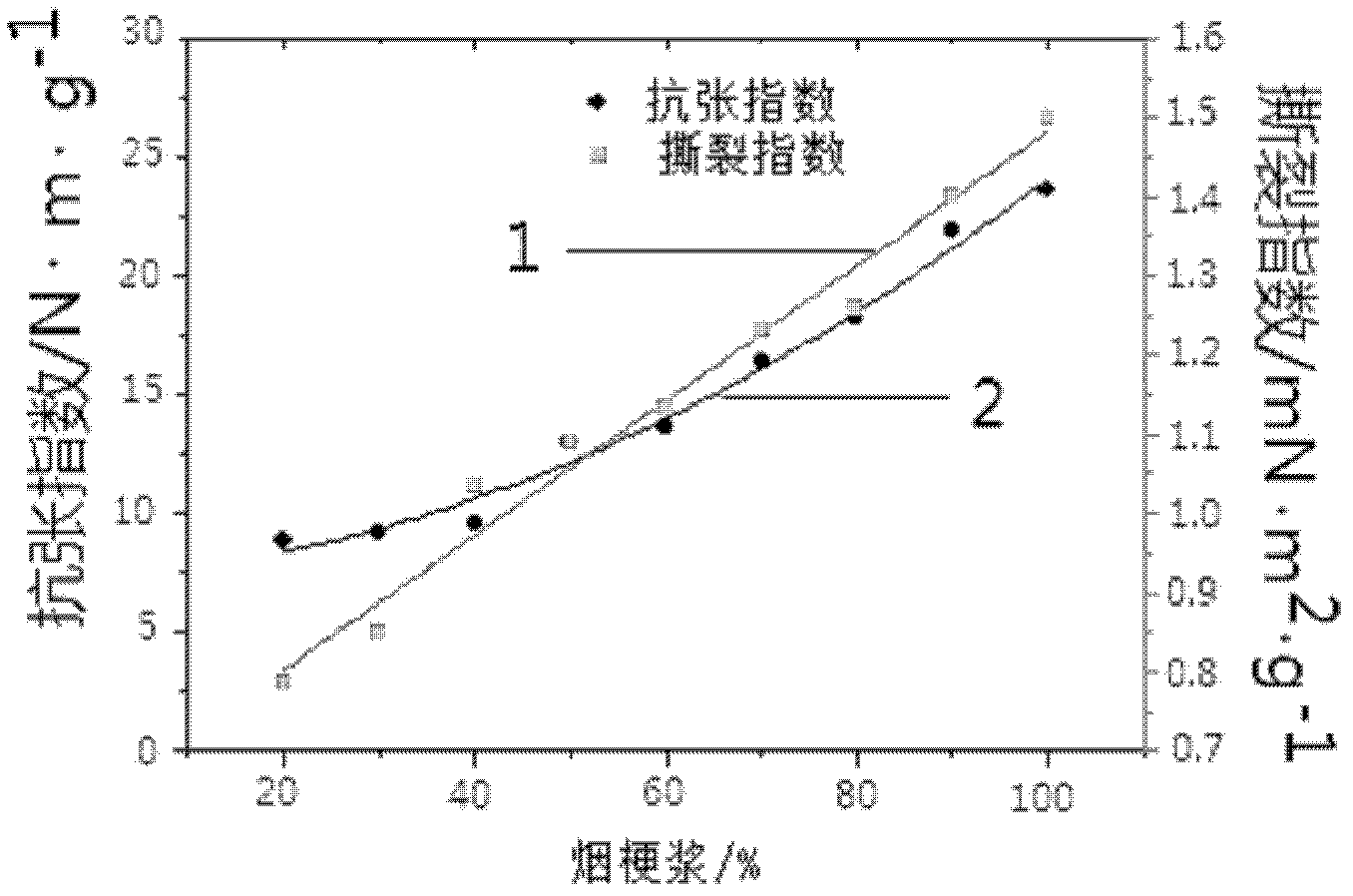

[0085] Example 2 Effect of the Proportion of Tobacco Stem and Tobacco Powder on the Properties of Tobacco Sheet Paper Base

[0086] The tobacco stems and tobacco powder used in the experiment were provided by Guangdong China Tobacco Industry Co., Ltd., which were commercially available tobacco stems and tobacco powder. Refrigerate the tobacco stems and tobacco powder at 4°C, and pack them into bags to balance the moisture for later use.

[0087] (1) Dipping extraction

[0088] In this example, the single-stage immersion extraction experiment of tobacco stems and tobacco powder was carried out in an electric cooking pot (ordinary type) ZT1-00 / 15L (produced by Xingping Zhongtong Experimental Equipment Co., Ltd.). Tobacco stem extraction: The amount of tobacco stems in the pot is 1500g. First add about 10000mL of water into the cooking pot according to the liquid ratio of 1:7 (mass ratio), preheat to 60°C, add the tobacco stems, cover the pot and carry out rotary cooking, keep ...

Embodiment 3

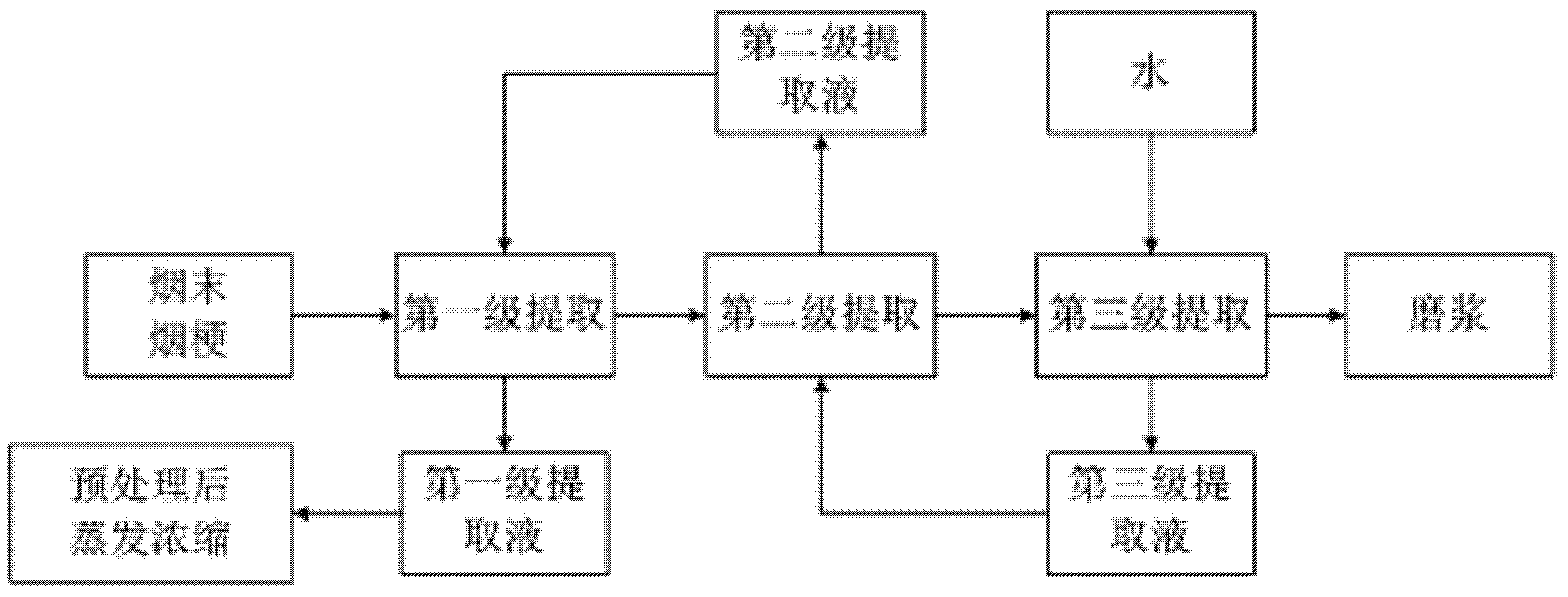

[0123] The preparation technology optimization experiment of embodiment 3 steeping extract

[0124] Tobacco stems and tobacco powder materials are the same as in Example 2 and Example 3.

[0125] (1) Single-stage immersion extraction method: The single-stage immersion extraction experiment of tobacco stems and tobacco dust was carried out in a digital display constant temperature water bath (Jinyi HHS type). First put the tobacco stems and tobacco powder into polyethylene sealed bags respectively, add a certain volume of distilled water according to the experimental conditions, put them in a water bath that has been raised to the required temperature, and keep warm for a specified time. During the immersion extraction, rub it every 10 minutes to make the reaction even. After the single-stage immersion extraction is completed, it is squeezed and dehydrated in a 120-mesh polyester net, and the extract is collected for corresponding chemical analysis.

[0126] (2) Three-stage c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com