Flaky metal powder production process

A production process and technology of metal powder, applied in the field of metal powder production process, can solve problems such as complicated procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

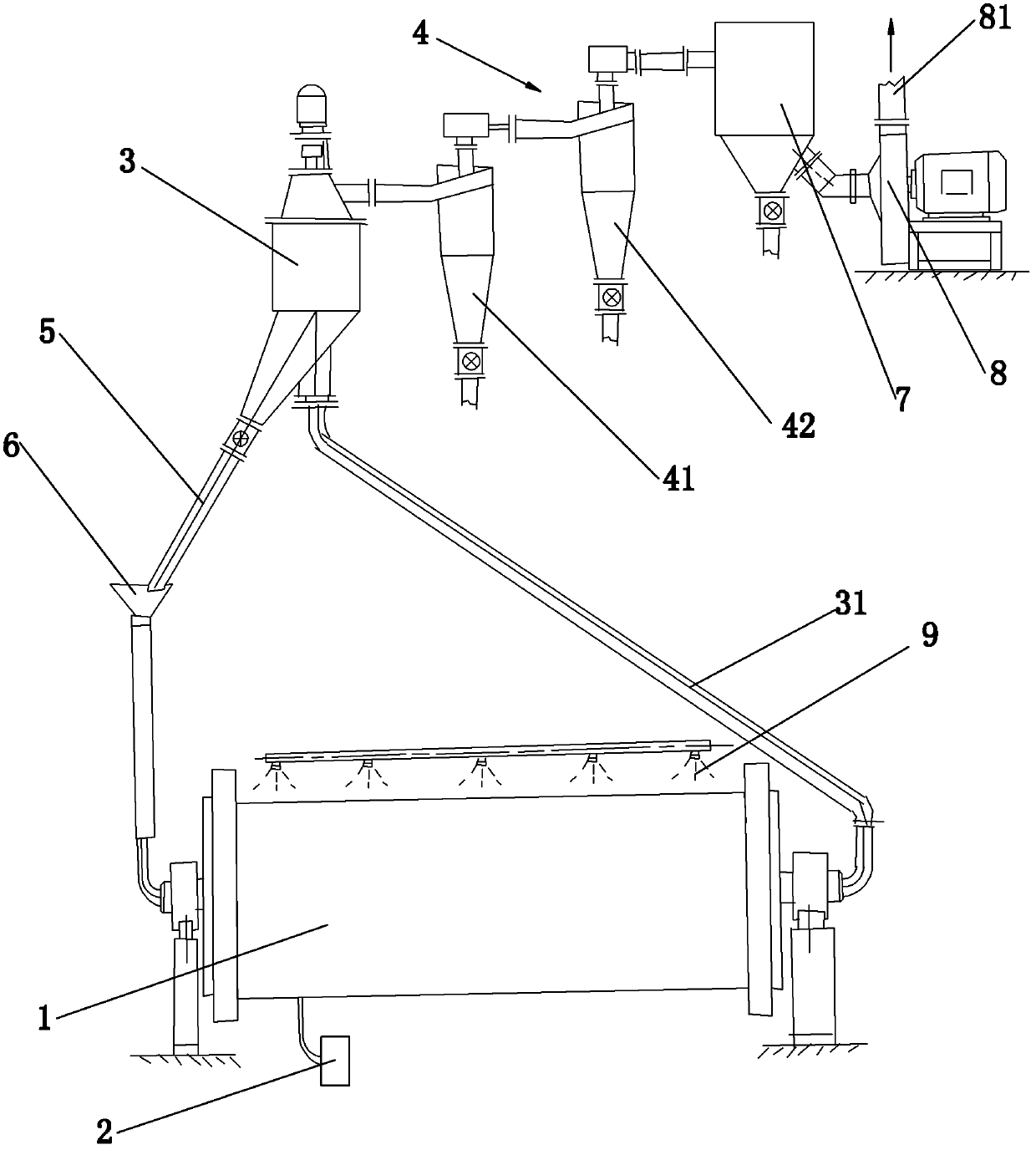

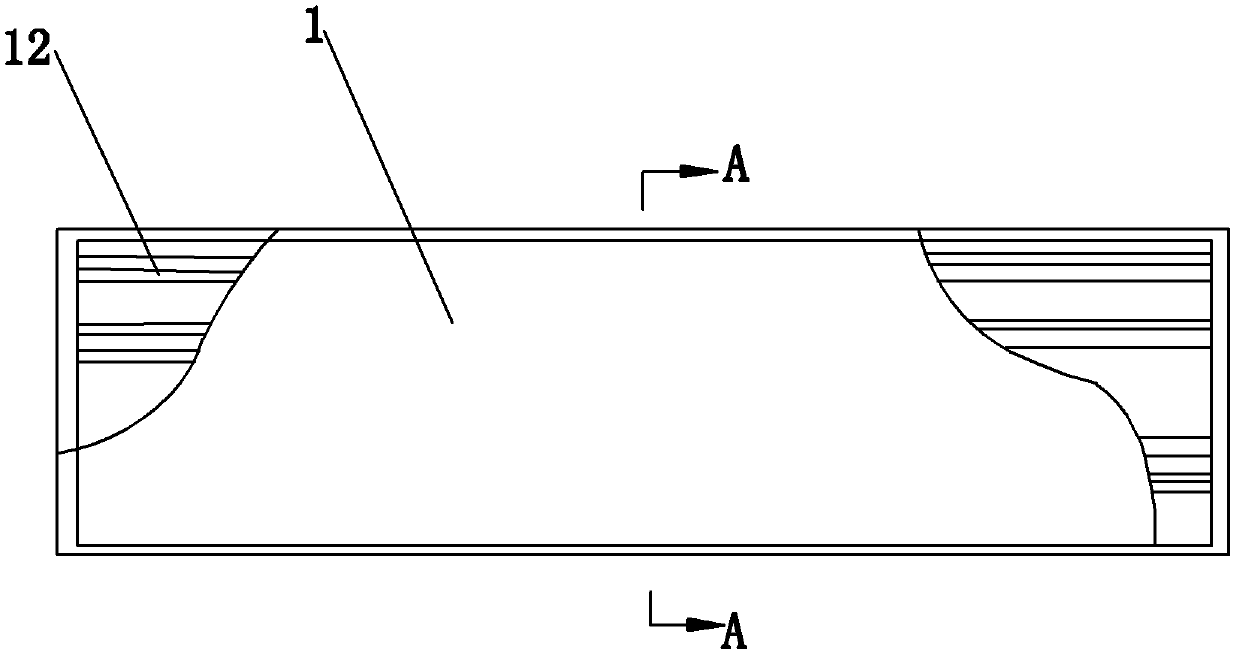

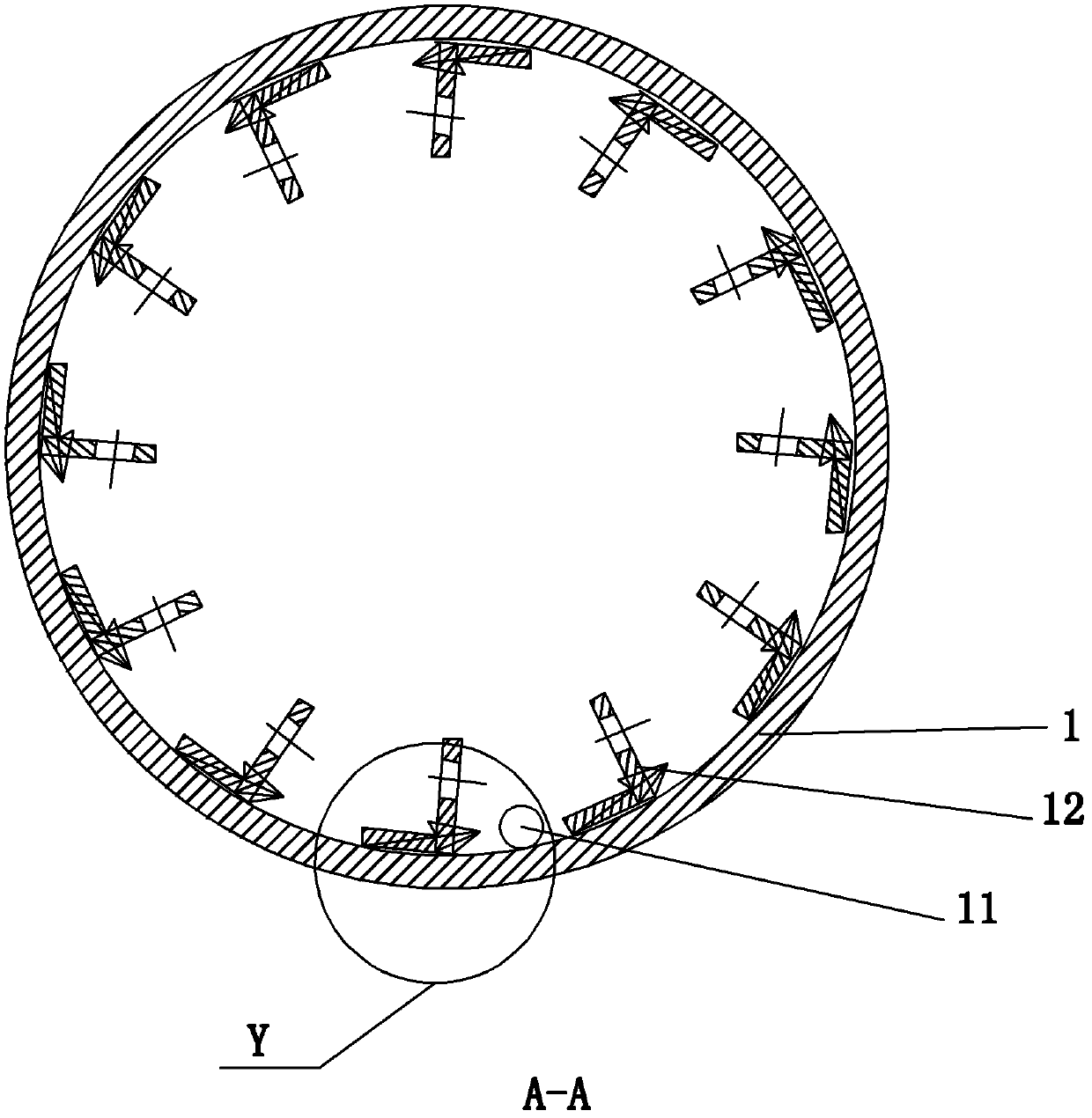

[0028] refer to Figure 1 to Figure 4 The embodiment of the production process of the scaly metal powder of the present invention will be further described.

[0029] The cylindrical ball mill 1 is provided with steel balls 11 (it should be noted here that the ratio of the total mass of the steel balls 11 to the total mass of the powder is 1:8 to 1:10) and 8 to 12 Lifting bars 12, the lifting bars 12 are distributed in a uniform circumferential structure, and the steel balls 11 are placed between the two lifting bars 12. Due to the rotation of the cylindrical ball mill 1 (it should be noted here that the cylindrical ball mill The rotational speed of the cylindrical ball mill 1 is adjustable, and its adjustment is adjusted by the frequency converter 2, which can change the rotational speed of the cylindrical ball mill 1 according to the particle size and production specifications of the metal powder, so as to achieve the crushing and grinding capacity conversion), the steel bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com