Waste brick recycled concrete building material and manufacturing method thereof

A technology of recycled concrete and production methods, which is applied in the field of building materials, can solve the problems of waste and old bricks from construction waste and environmental problems, the effects of waste bricks are not fully utilized, and the composition of binders is too large, so as to alleviate the shortage of building materials supply and the production method Reliable, effective in addressing governance and environmental concerns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

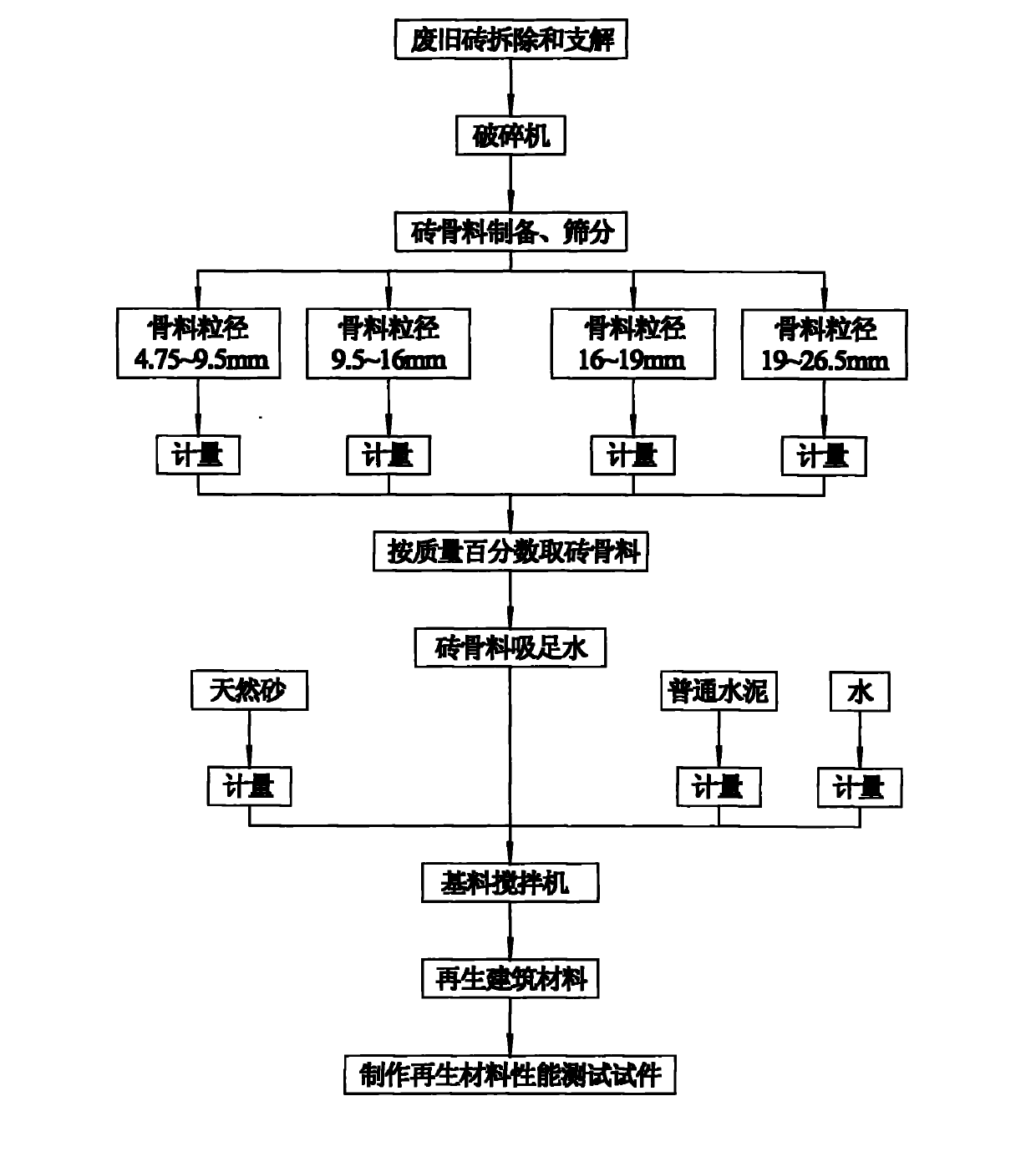

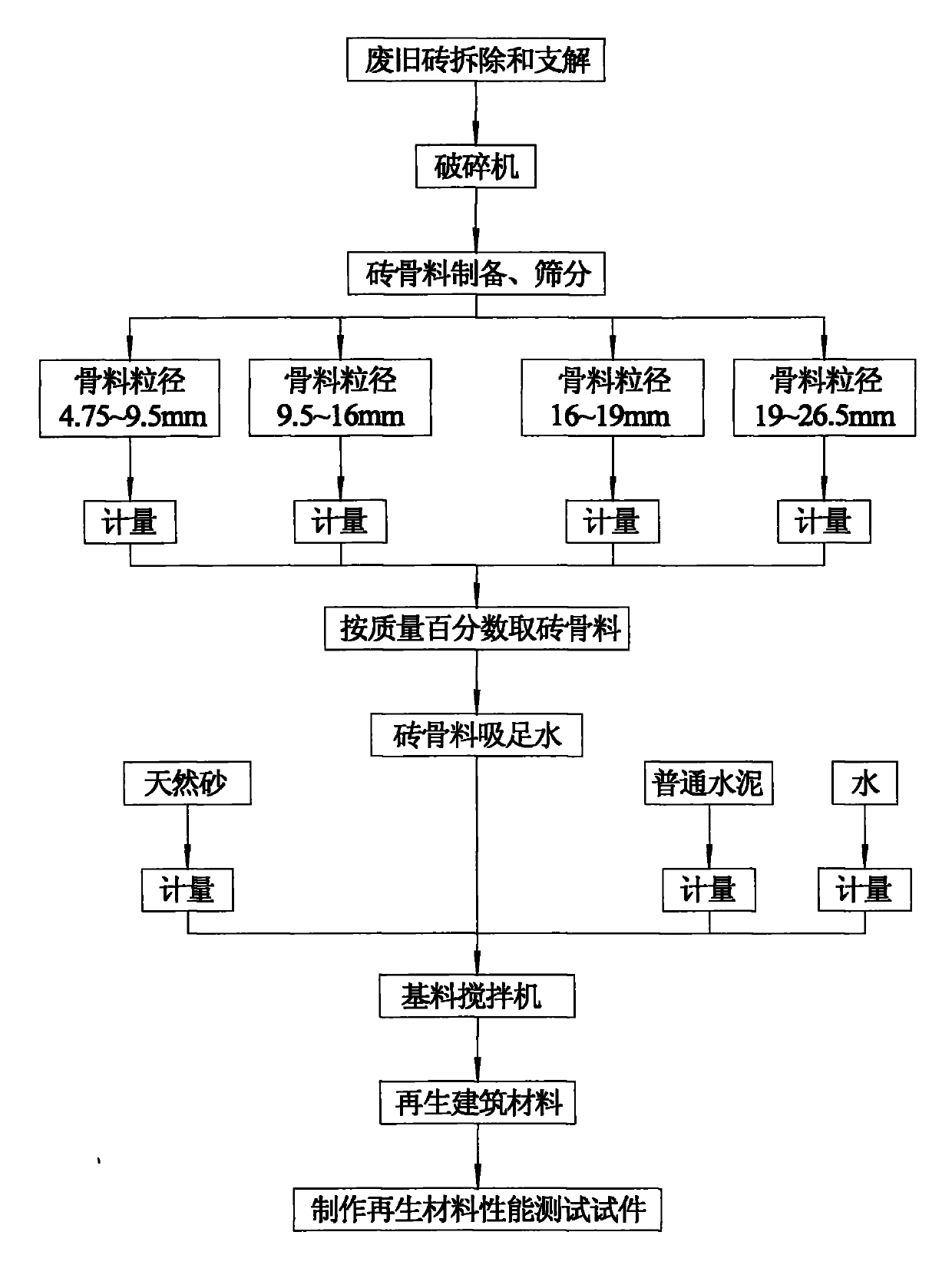

Method used

Image

Examples

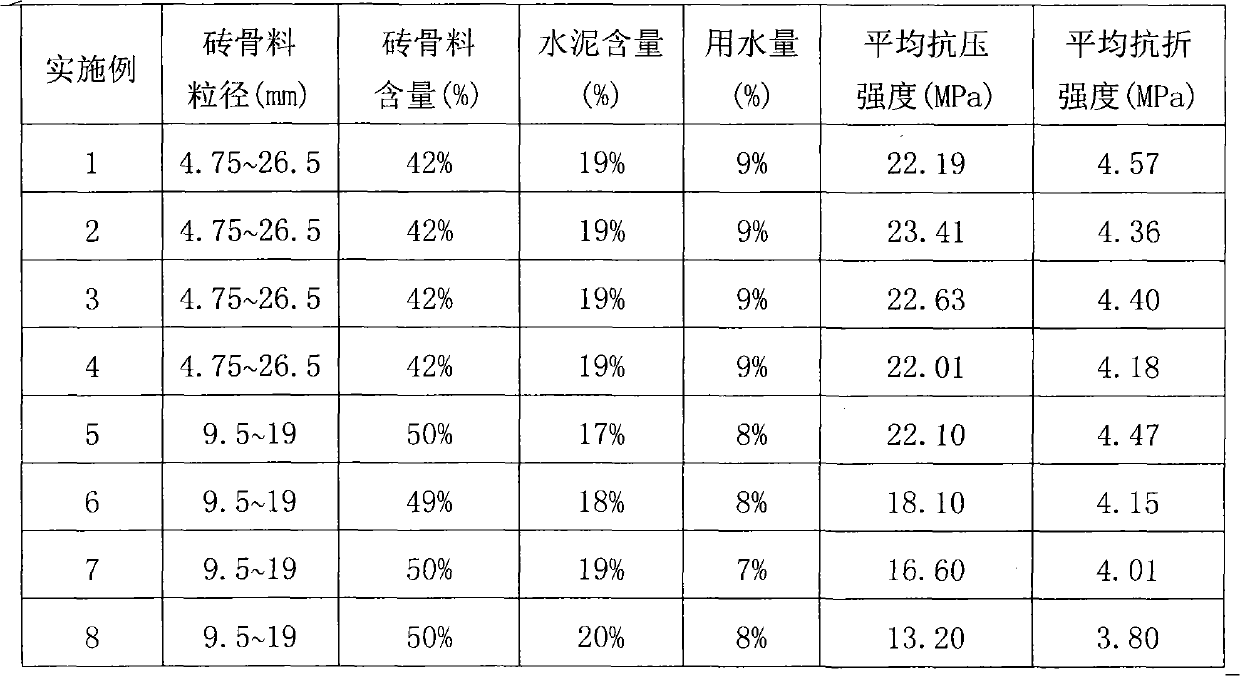

Embodiment 1

[0024] Raw material composition and weight percentage thereof are as follows:

[0025] Brick aggregate: 42%

[0026] Sand: 30%

[0027] Cement: 19%

[0028] Water: 9%

[0029] Among them: the weight percentage distribution of brick aggregates with different particle sizes is as follows: particle size 4.75-9.5mm accounts for 10%, particle size 9.5-16mm accounts for 20%, particle size 16-19mm accounts for 20%, particle size 19-26.5mm accounts for 50% .

[0030] The manufacturing method steps of the present embodiment are as follows:

[0031] (1) Brick aggregate preparation

[0032] After dismantling and dismantling the waste bricks or broken bricks, clean up the surface impurities; crush the bricks into aggregates through a crusher, and pay special attention to improving the utilization rate of bricks during the process of breaking into aggregates. The particle size range of aggregates is selected as 4.75mm~26.5mm; Put the brick aggregate in water for a period of time to e...

Embodiment 2

[0038] Raw material composition and weight percentage thereof are as follows:

[0039] Brick aggregate: 42%

[0040] Sand: 30%

[0041] Cement: 19%

[0042] Water: 9%

[0043] Among them: the weight percentage distribution of brick aggregates with different particle sizes is as follows: particle size 4.75-9.5mm accounts for 10%, particle size 9.5-16mm accounts for 20%, particle size 16-19mm accounts for 50%, particle size 19-26.5mm accounts for 20% .

[0044] The manufacturing method steps of the present embodiment are as follows:

[0045] (1) Brick aggregate preparation

[0046] With embodiment 1.

[0047] (2) Raw material preparation

[0048] With embodiment 1. Features of this embodiment: among the particle size contents of the four gradations, the particle size 16-19mm and the particle size 19-26.5mm account for 50% and 20% respectively, and the other particle size contents are the same as in Example 1.

[0049] (3) Production and molding of recycled materials

...

Embodiment 3

[0052] Raw material composition and weight percentage thereof are as follows:

[0053] Brick aggregate: 42%

[0054] Sand: 30%

[0055] Cement: 19%

[0056] Water: 9%

[0057] Among them: the weight percentage distribution of brick aggregates with different particle sizes is as follows: particle size 4.75-9.5mm accounts for 20%, particle size 9.5-16mm accounts for 50%, particle size 16-19mm accounts for 20%, particle size 19-26.5mm accounts for 10% .

[0058]The manufacturing method steps of the present embodiment are as follows:

[0059] (1) Brick aggregate preparation

[0060] With embodiment 1.

[0061] (2) Raw material preparation

[0062] With embodiment 1. Features of this embodiment: in the particle size content of four kinds of gradations, particle size 4.75~9.5mm, particle size 9.5~16mm, particle size 16~19mm and particle size 19~26.5mm respectively account for 20%, 50%, 20% and 10%.

[0063] (3) Production and molding of recycled materials

[0064] With em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com