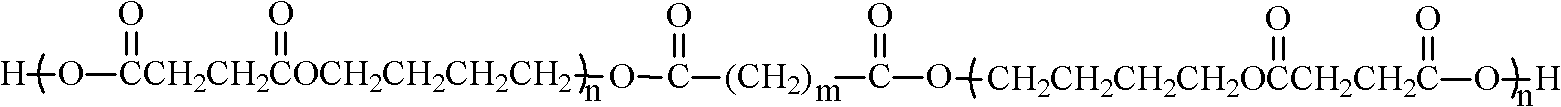

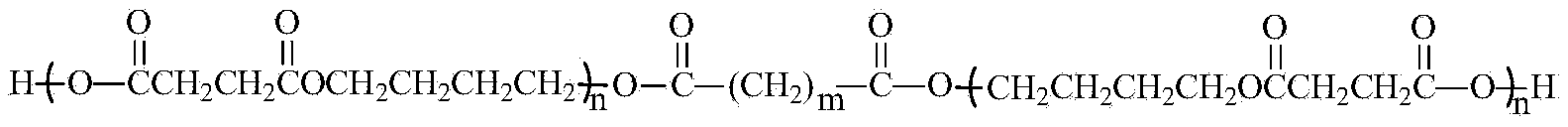

Poly(butylene succinate) and preparation method thereof

A technology of polybutylene succinate and succinic acid is applied in the field of high molecular weight polybutylene succinate and its preparation, which can solve the problems such as limiting the application scope of the product, and achieves low cost, short time, and low cost. Less side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Solution esterification stage: Add succinic acid, 1,4-butanediol, toluene, stannous chloride and p-toluenesulfonic acid into the reflux water separation reaction device, stir and heat up, and reflux water separation at 140°C After 60 minutes, the toluene was evaporated, and the succinic acid: 1,4-butanediol: tin protochloride: the mol ratio of p-toluenesulfonic acid was 1: 1.1: 0.002: 0.001, every time 1 mole of succinic acid was added Then correspondingly add 500 milliliters of toluene; (2) melt polycondensation stage: after steaming out the toluene, change the reflux water separation device to a vacuum device, protect with nitrogen, stir and heat up, and melt and polycondense for 60 minutes at 230° C. and 5 mmHg vacuum degree; 3) Dibasic acid chloride chain extension stage: return to normal pressure after step (2), lower the temperature to 130°C, install a gas absorption device, pass nitrogen protection, and then add chain extender dibasic acid chloride under rapid...

Embodiment 2

[0024] (1) Solution esterification stage: Add succinic acid, 1,4-butanediol, toluene, stannous chloride and p-toluenesulfonic acid into the reflux water separation reaction device, stir and heat up, at 145 ° C, reflux separation After 120 minutes of water, the toluene was evaporated, and the succinic acid: 1,4-butanediol: tin protochloride: the mol ratio of p-toluenesulfonic acid was 1: 1.1: 0.002: 0.001, every time 1 mole of butanediol was added Add 500 ml of toluene to the acid; (2) melt polycondensation stage: change the reflux water separation device to a vacuum device after steaming out the toluene, protect with nitrogen, stir and heat up, and melt and polycondense at 230 ° C and 5 mmHg vacuum for 120 minutes; (3) Dibasic acid chloride chain extension stage: After step (2), return to normal pressure, lower the temperature to 150°C, install a gas absorption device, pass nitrogen protection, and then add chain extender dibasic acid chloride under rapid stirring to react at n...

Embodiment 3

[0026] (1) Solution esterification stage: Add succinic acid, 1,4-butanediol, toluene, stannous chloride and p-toluenesulfonic acid into the reflux water separation reaction device, stir and heat up, and reflux water separation at 150°C After 90 minutes, the toluene was evaporated, and the succinic acid: 1,4-butanediol: tin protochloride: the mol ratio of p-toluenesulfonic acid was 1: 1.1: 0.002: 0.001, every time 1 mole of succinic acid was added Then correspondingly add 500 milliliters of toluene; (2) melt polycondensation stage: after steaming out the toluene, change the reflux water separation device to a vacuum device, protect with nitrogen, stir and heat up, and melt and polycondense for 90 minutes at 230° C. and 5 mmHg vacuum degree; 3) Dibasic acid chloride chain extension stage: return to normal pressure after step (2), lower the temperature to 170°C, install a gas absorption device, pass nitrogen protection, and then add chain extender dibasic acid chloride under rapid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com