Prefabrication and construction method of box girder in-situ pedestal

A construction method and pedestal technology, which are applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as a large amount of space for via holes, affecting engineering construction, affecting tunnel construction, etc., to improve the stress effect, easy operation and economical. Outstanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

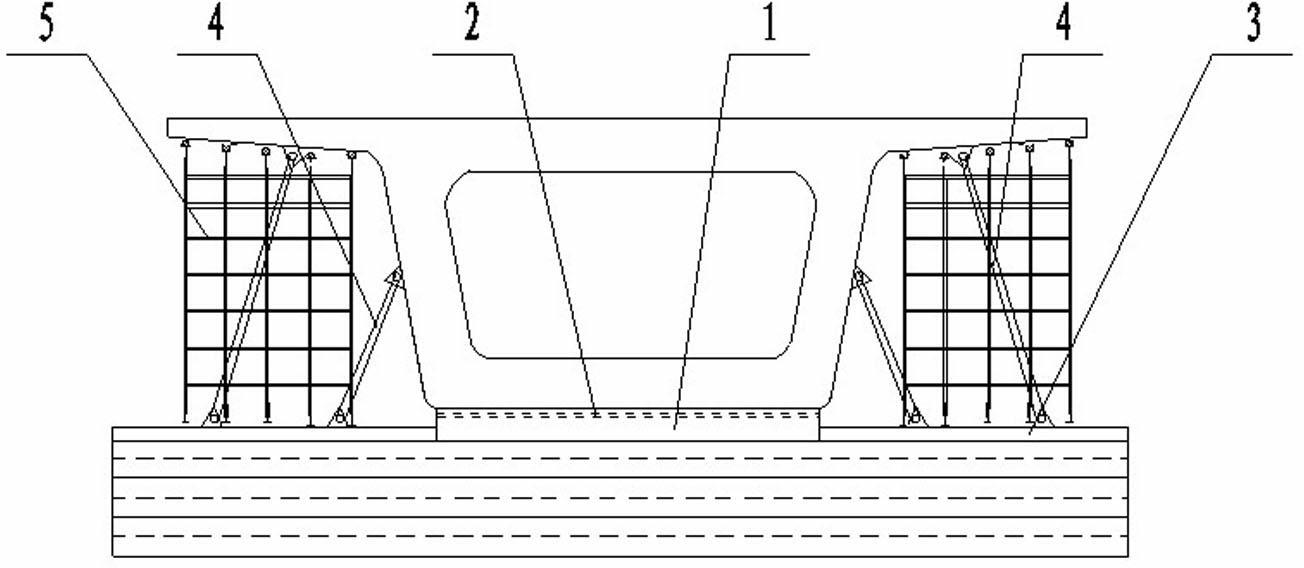

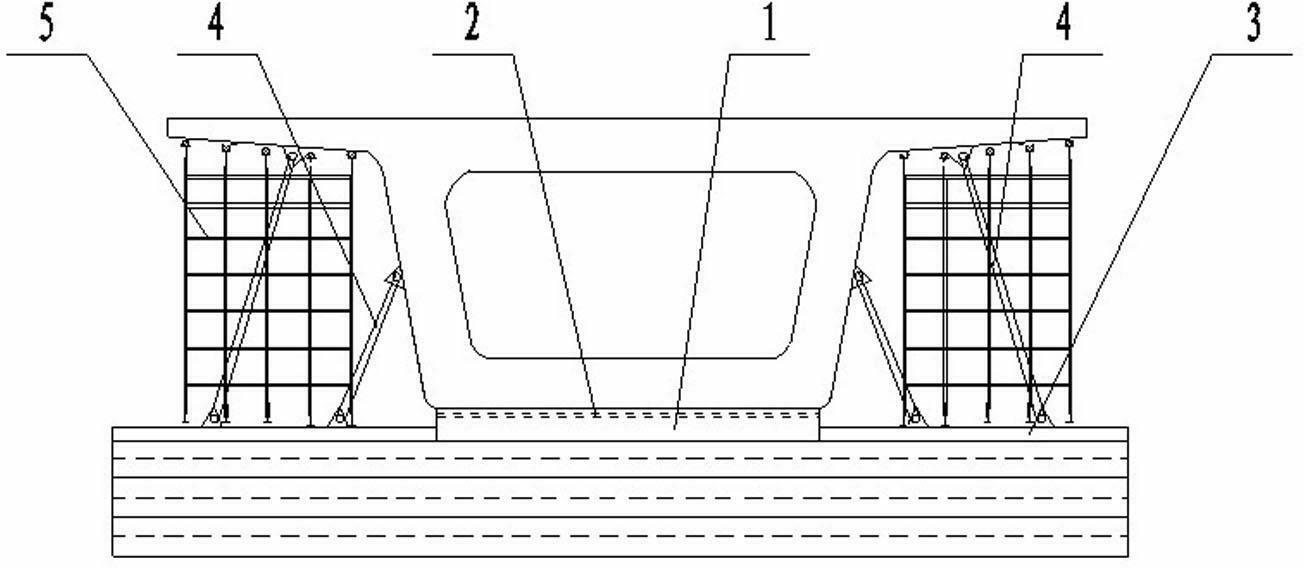

[0009] The prefabricated construction method of the in-situ pedestal of the box girder adopts the following steps: a. Measure and set out, determine the position of the box girder body and the range and height of the foundation treatment, perform replacement, layered rolling, and backfill and tamp around the abutment; b. Concrete pedestal 1 is poured in vertical form as the bottom form, and tie rod holes 2 are reserved under the top surface of pedestal 1, and concrete foundation 3 is poured around pedestal 1; The strut 4 connected to the concrete foundation 3 is used to adjust the elevation of the top of the side form, and the side form is reinforced by the bowl button scaffold 5, and the top of the scaffold 5 is provided with adjustable jacking and square timber; d. Preloading the side form , eliminate the inelastic deformation of the foundation and scaffolding 5, and re-correct the elevation of the foundation and side forms according to the preloading results; e, after instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com