Quick metal cutting strip by means of combustion

A technology for cutting strips and metals, applied in the burner, combustion method, combustion type, etc., can solve the problems of cutting depth limitation, high price, complex structure, etc., and achieve the effect of reducing gas resistance, low production cost and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

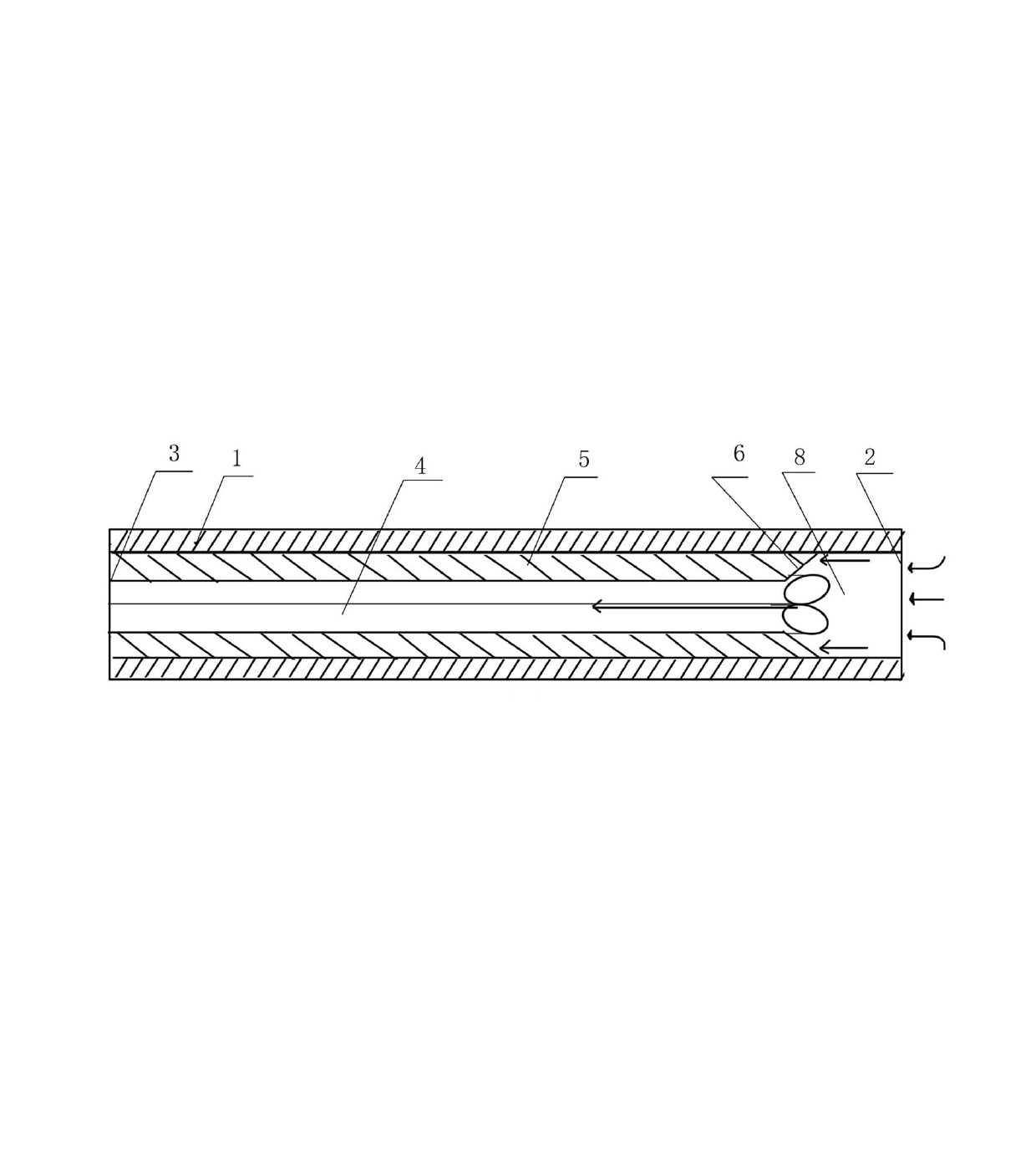

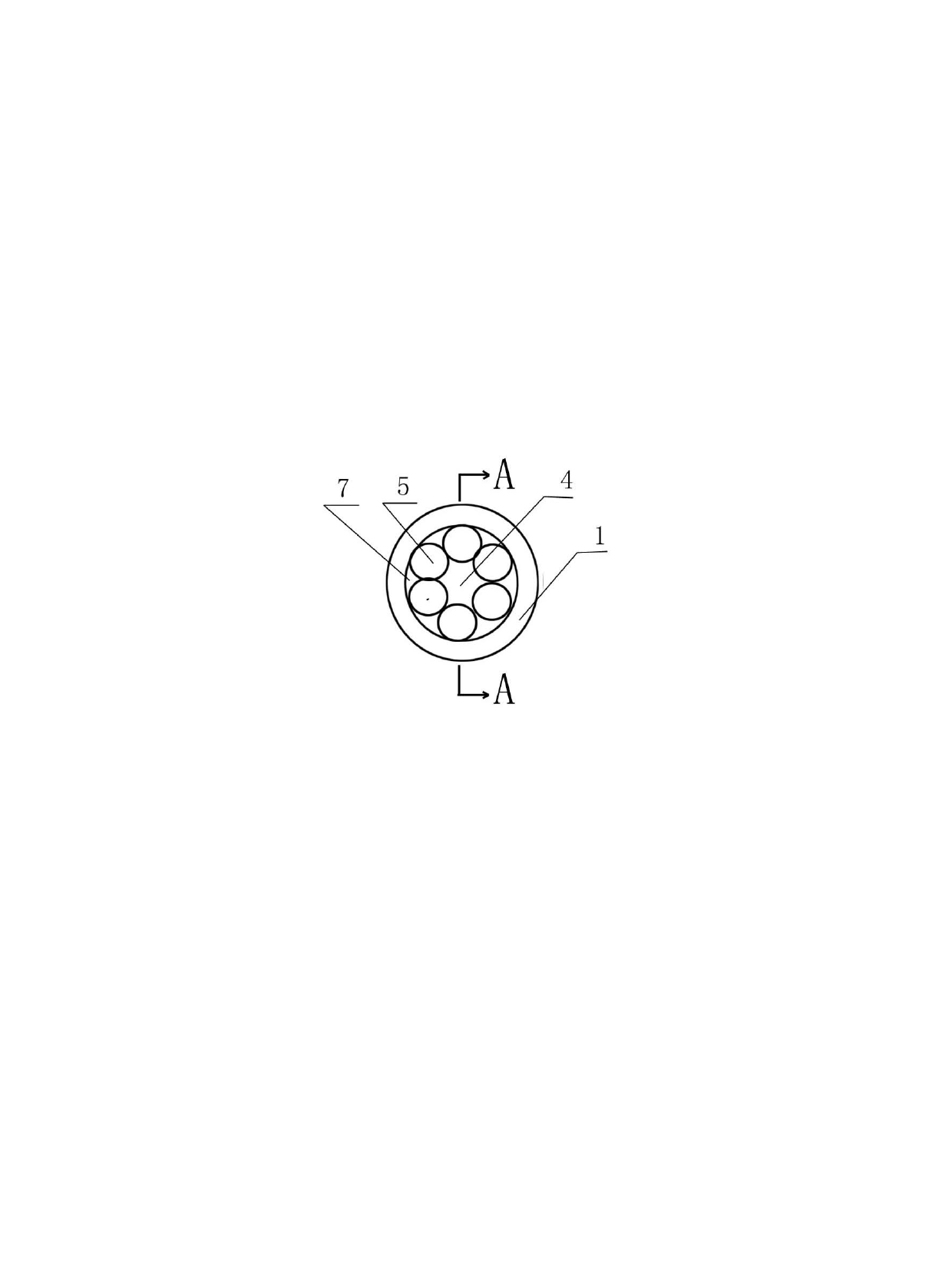

[0009] exist figure 1 and figure 2 Among them, the present invention is a kind of burning metal quick cutting strip, it comprises iron pipe 1, and the diameter of iron pipe 1 is less than 70MM, and this embodiment adopts 8.15MM, and one end of iron pipe 1 is air inlet end 2, and the other end is air outlet end 3. The center of the iron pipe 1 is set as an air path I4, and several coated iron wires 5 are evenly inserted in the iron pipe 1. In this embodiment, six coated iron wires 5 are inserted, and the coated iron wires 5 are set as galvanized iron wires, copper-plated iron wires, Nickel iron wire or chromium-plated iron wire, the diameter of the coated iron wire 5 is greater than 2MM and less than 10MM. This embodiment adopts 2.15MM. On the inner wall of the iron pipe 1, the inside of each coated iron wire 5 surrounds the gas path I4, and a gap 6 is provided between the outer sides of the coated iron wire 5, and an independent gas path II7 is formed between each gap 6 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com