Dry-wet combined industrial circulating water cooling system

An industrial circulating water and wet cooling technology, applied in the direction of water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problems that cannot meet industrial production, have not been widely used, and the temperature of circulating water outlet is high. problems, to achieve the effect of less water consumption, low temperature and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

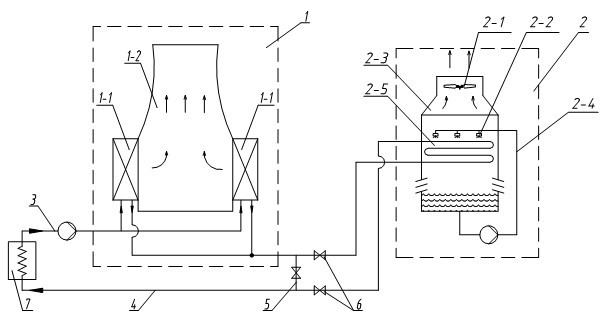

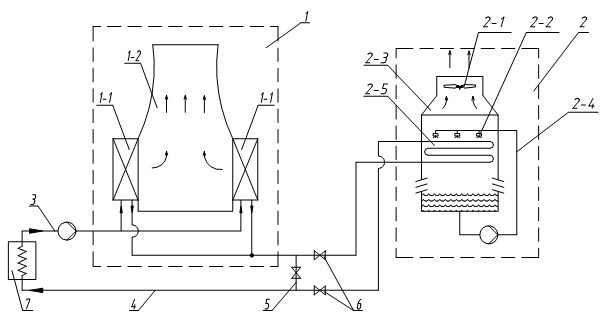

[0017] see figure 1 , figure 1 It is a schematic diagram of Embodiment 1 for implementing the present invention. Depend on figure 1 It can be seen that the dry-wet combined industrial circulating water cooling system of the present invention includes a dry cooling tower 1, a closed wet cooling tower 2, a water inlet pipe 3, a water return pipe 4, a bypass pipe 5 and a valve 6 , the dry cooling tower 1 is composed of a dry cooling tower body 1-2 and an air-cooling radiator 1-1, and the air-cooling radiator 1-1 is arranged in the dry cooling tower body 1-2 or around the tower body, and the closed wet cooling tower 2 is composed of Wet cooling tower body 2-3, cooling fan 2-1, cooling water pipe 2-4, cooling water nozzle 2-2 and cooling coil 2-5, dry cooling tower 1 and closed wet cooling tower 2 are arranged in series, After the industrial circulating water exits the dry cooling tower 1, a bypass pipe 5 connected to the return water main pipe 4 is set on the pipeline before en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com