Steel ball size detecting device

A detection device, steel ball technology, applied in the direction of mechanical diameter measurement, etc., can solve the problem of CV universal joint product flow to the next process, etc., to eliminate potential risks of automobiles, solve visual fatigue or lack of concentration, and improve detection reliability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

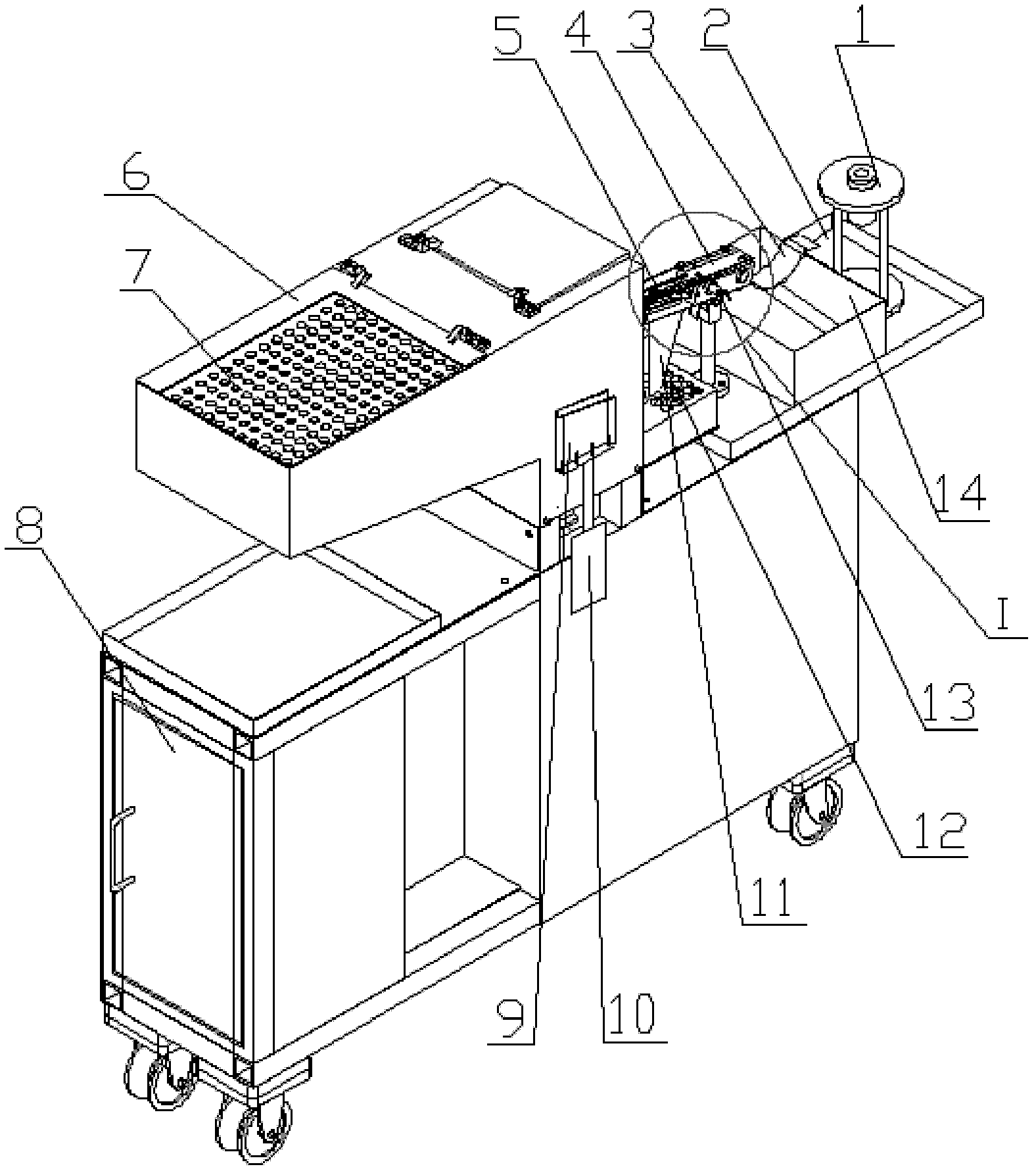

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

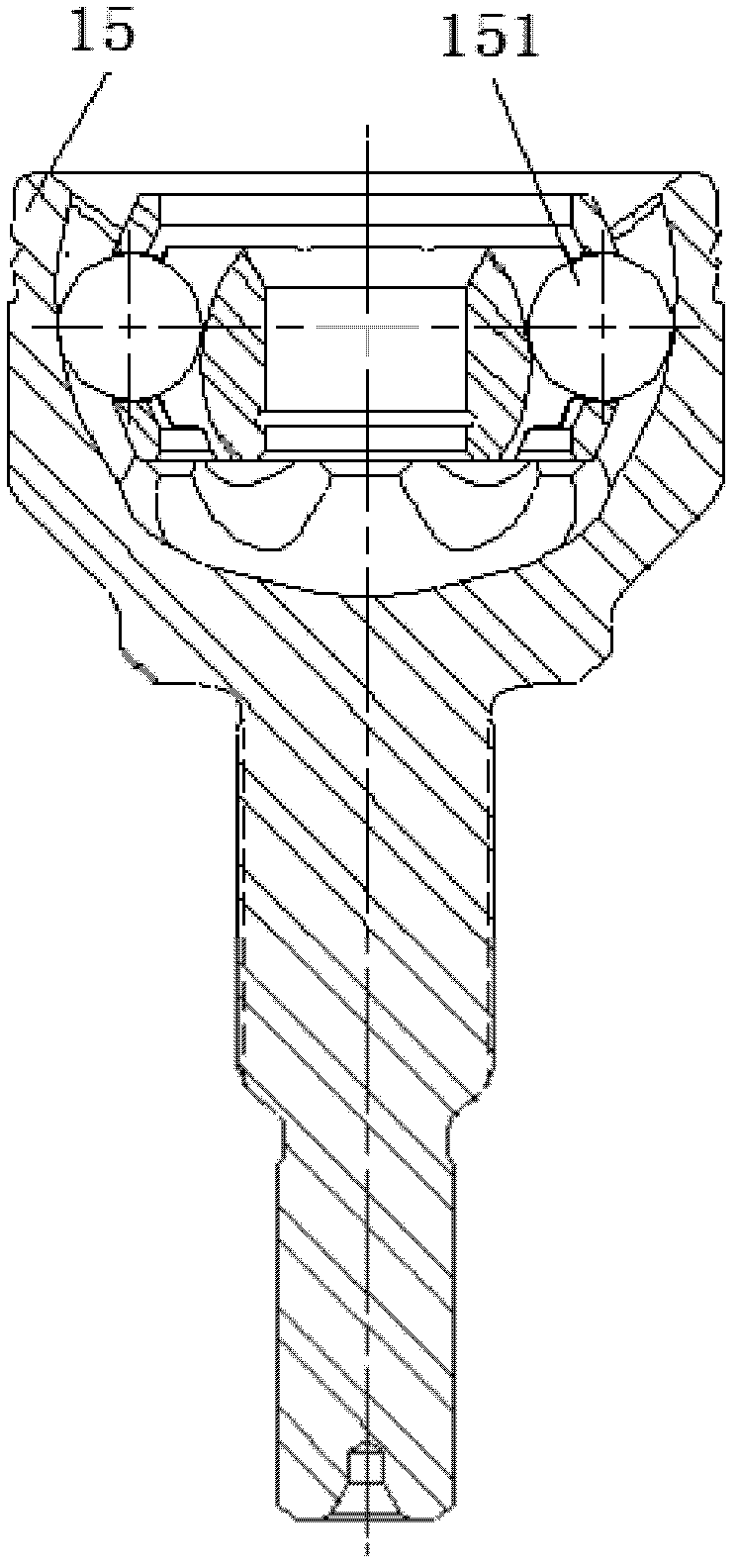

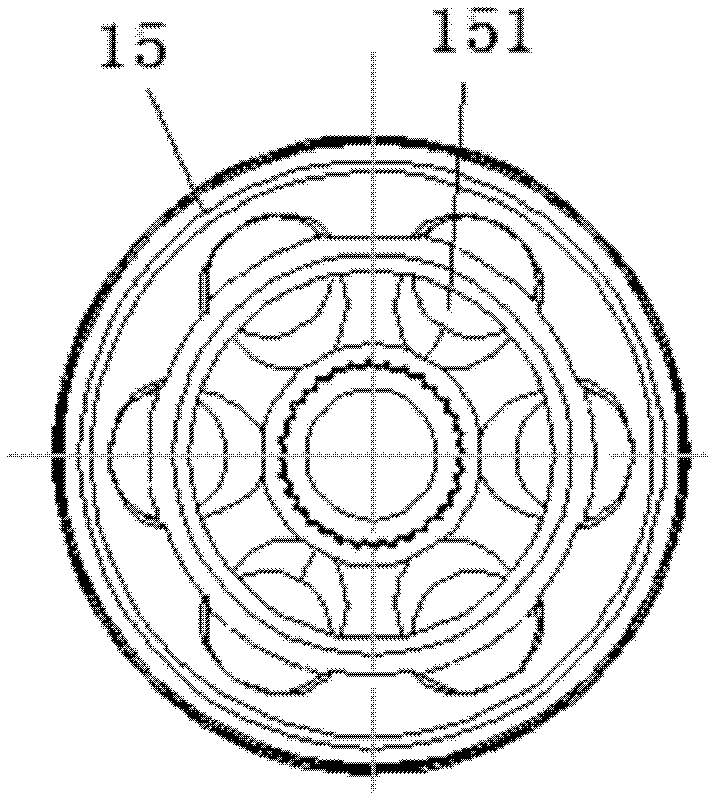

[0023] Such as figure 2 As shown, a steel ball size detection device described in the embodiment of the present invention includes a workbench 2, a storage bin 6, a screen 7, a slideway 5, a discharge port 3, a recycling channel 11 and a recycling box 12 , the storage bin 6 is arranged on the workbench 2, and the screen 7 is arranged on the upper part of the storage bin 6, and the screen 7 is used to screen out steel balls larger than the normal size. The storage bin 6 is used to store steel balls less than or equal to the normal size, and the storage bin 6 is connected to the slideway 5, and the slideway 5 is provided with an oblong groove 51 (see image 3 ), the oblong groove 51 (see image 3 ) width is slightly smaller than the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com