Raw silk quality detection method and system in silk reeling production

A quality inspection method and raw silk technology, applied in weighing, measuring devices, instruments, etc., can solve the problems of inconvenience for enterprise managers to produce information, affect the timeliness of data, and low data accuracy, so as to facilitate timely understanding and mastery , easy operation and maintenance, and the effect of improving the quality of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

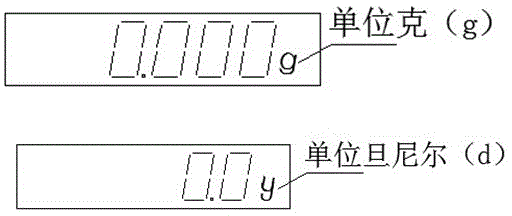

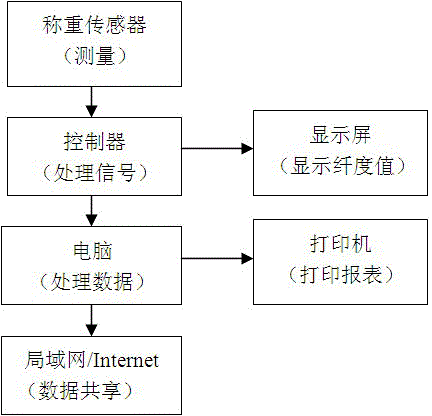

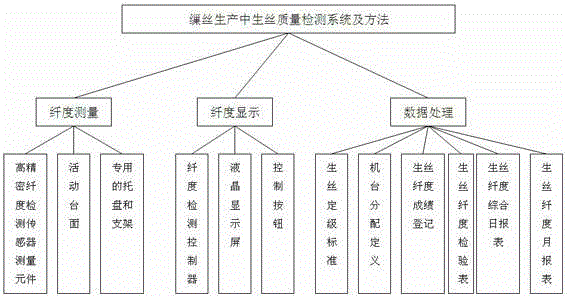

[0064] The general scheme of the present invention is as follows: first, establish a central database of the raw silk fineness automatic detection system, enter the raw silk grading standards and machine allocation definitions involved in the quality detection into the central database, and then the quality inspectors start weighing silk. When weighing, the worker puts a skein of raw silk on the tray, and the fineness detection sensor automatically measures the fineness value of the raw silk, and converts the fineness value information into an electrical signal and displays it through the connecting cable to the controller of the display control part. At the same time, the controller passes through Automatically process the data signal converted into the actual fineness value, through the connection with RS232 or RJ45 interface, automatically read and record into the raw silk fineness automatic detection system of the all-in-one computer, and display it in the registration form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com