Roadbed dynamic response in-situ test system and roadbed dynamic response in-situ test method

A technology of subgrade dynamics and in-situ testing, applied in the field of subgrade testing, to achieve the effect of actively controlling test conditions and realizing on-site prototype testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

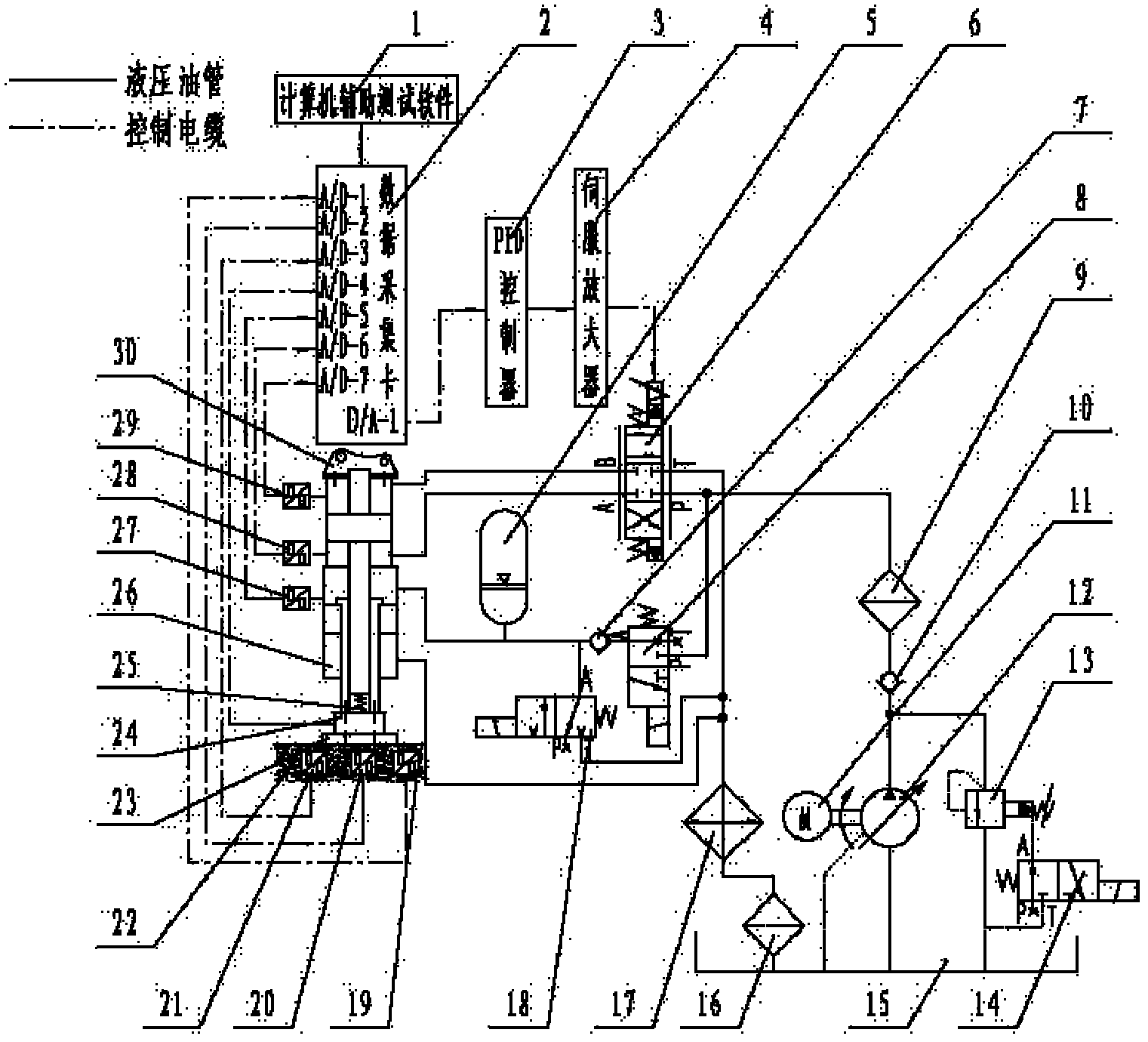

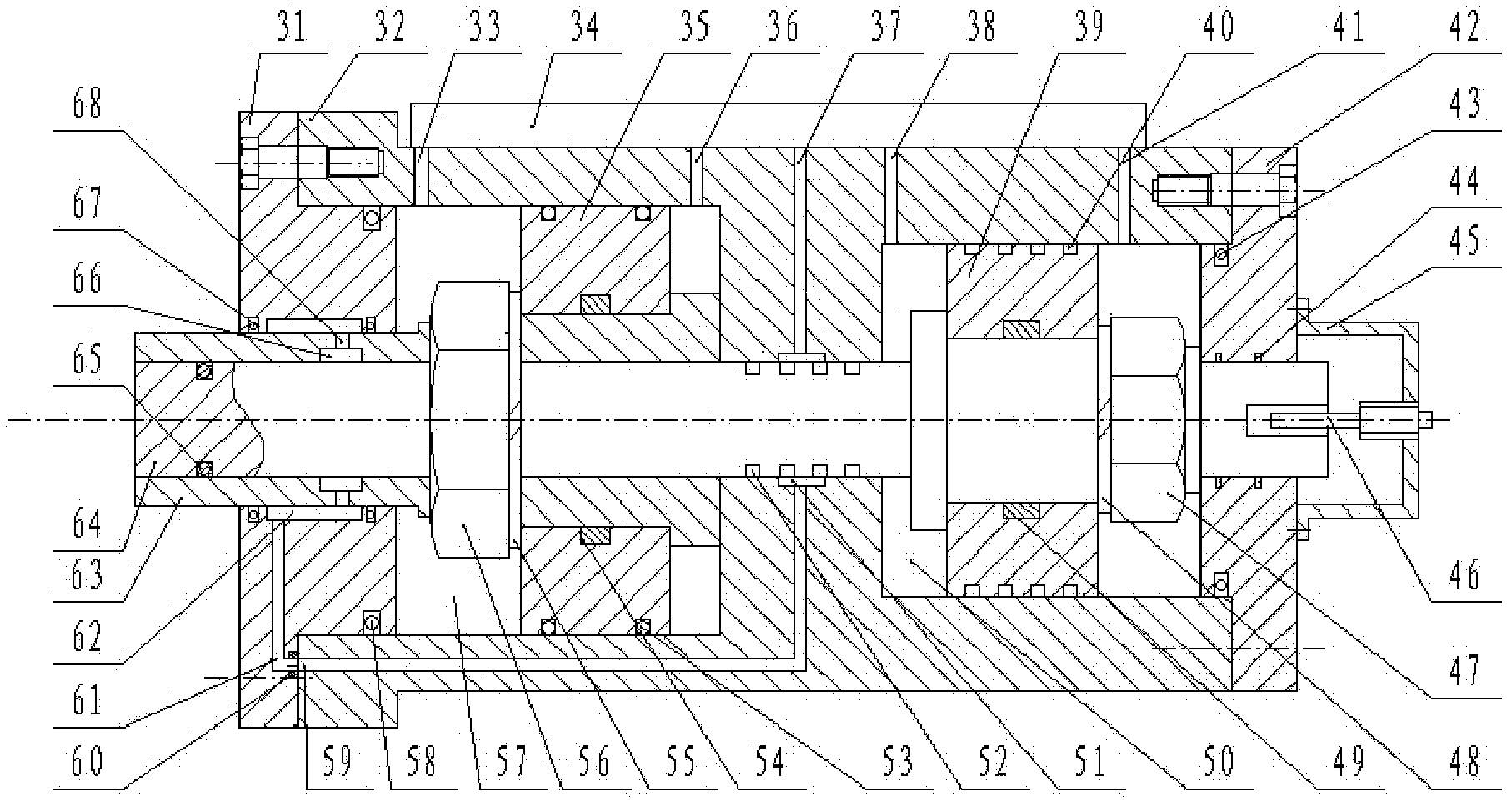

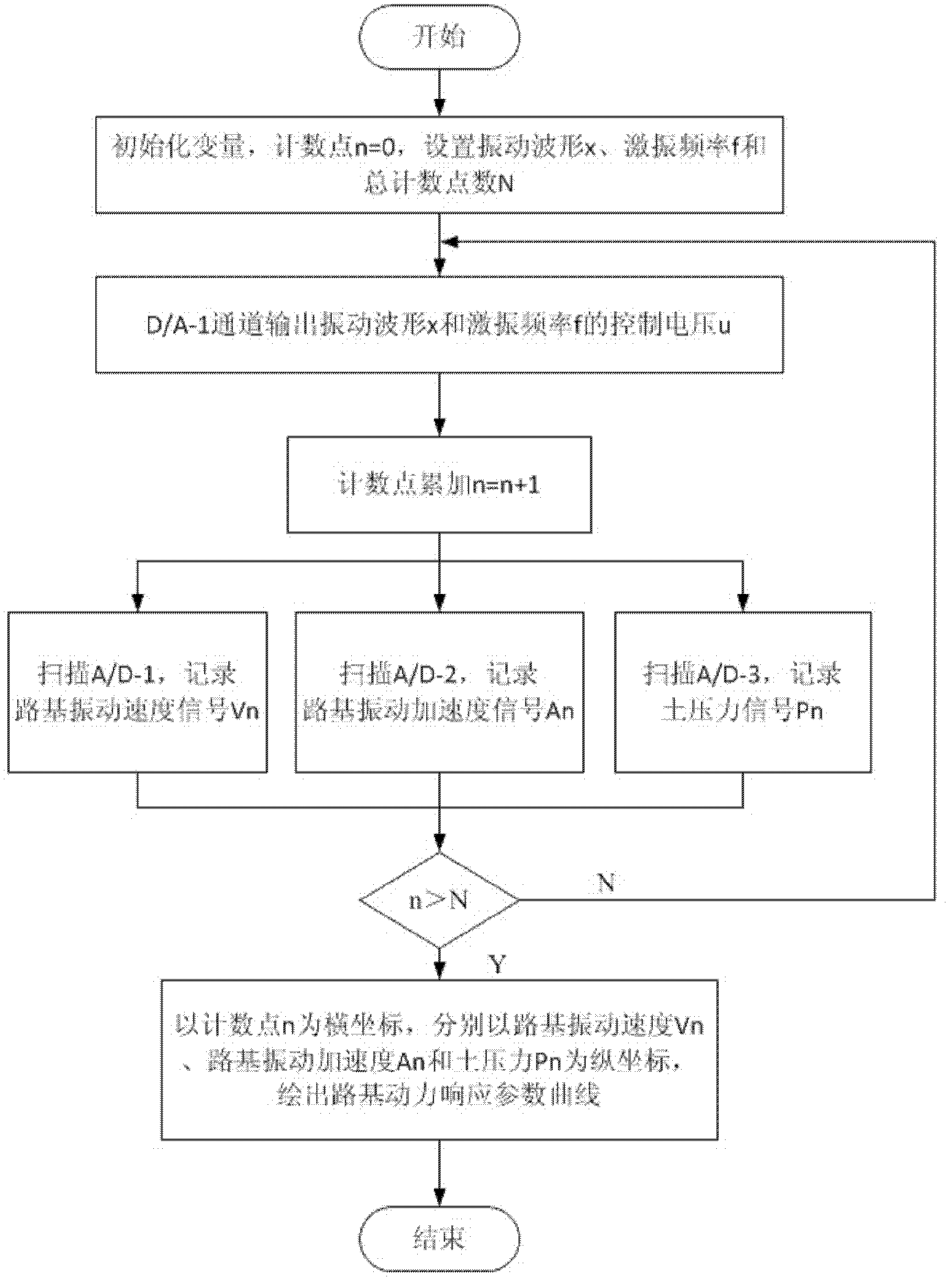

[0049] An in-situ test system and test method for roadbed dynamic response. The test system described is figure 1 As shown: the oil pump 12 is coaxially connected with the motor 11, the oil suction port of the oil pump 12 communicates with the oil tank 15 through the oil pipe, and the oil pressure port of the oil pump 12 connects with the oil inlet of the relief valve 13 and the inlet of the first check valve 10 through the oil pipe. The oil ports communicate with each other, the oil outlet of the relief valve 13 communicates with the oil tank 15 through the oil pipe, the control port of the relief valve 13 communicates with the A port of the second electromagnetic reversing valve 14, and the T port of the second electromagnetic reversing valve 14 Communicate with the oil tank 15 through the oil pipe, and the P port of the second electromagnetic reversing valve 14 is blocked; The oil outlet communicates with the P port of the electro-hydraulic servo valve 6 and the P port of ...

Embodiment 2

[0082] An in-situ test system and test method for roadbed dynamic response. Except following technical parameter, all the other are with embodiment 1.

[0083] The soil pressure sensor 21, acceleration sensor 20 and speed sensor 19 buried in the roadbed 22 means that the earth pressure sensor 21, acceleration sensor 20 and speed sensor 19 are placed at a depth of 200-1000 mm from the surface of the roadbed 22;

[0084] The outer wall of the dynamic pressure piston 39 is provided with 4 to 5 first balance grooves 40, and there are 5 to 6 first balance grooves 40 on the dynamic pressure piston rod 64 at the contact part of the central through hole of the cylinder partition wall. a second balance tank 52;

[0085] The width of the first leakage oil annular groove 62 is 1.5-2.0 times of the stroke of the static pressure piston 35 .

[0086] Owing to adopting above-mentioned technical scheme, this specific embodiment has following positive effect:

[0087] 1. This specific embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com