Method and equipment for confirming CT (Computed Tomography) scanning position in dangerous goods inspection system

A CT scanning and inspection system technology, applied in the field of radiation inspection, can solve the problems of radiation residue, heavy equipment, unsuitable automatic and fast inspection, etc., and achieve the effect of improving the detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

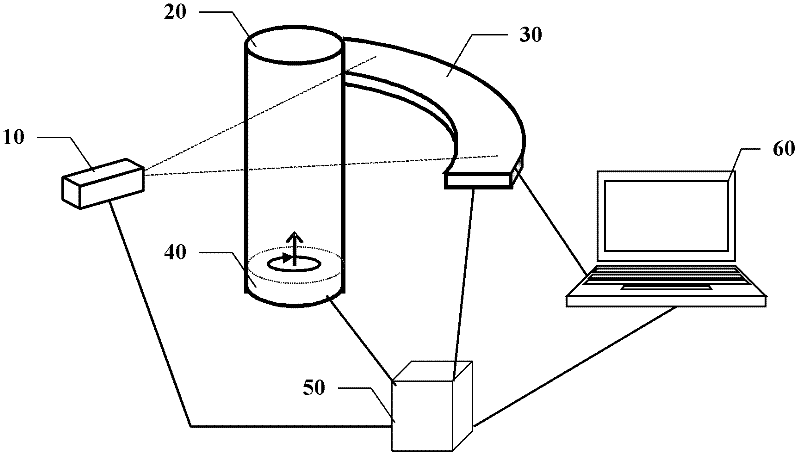

[0087] figure 1 is a schematic structural diagram of an inspection device according to an embodiment of the present invention.

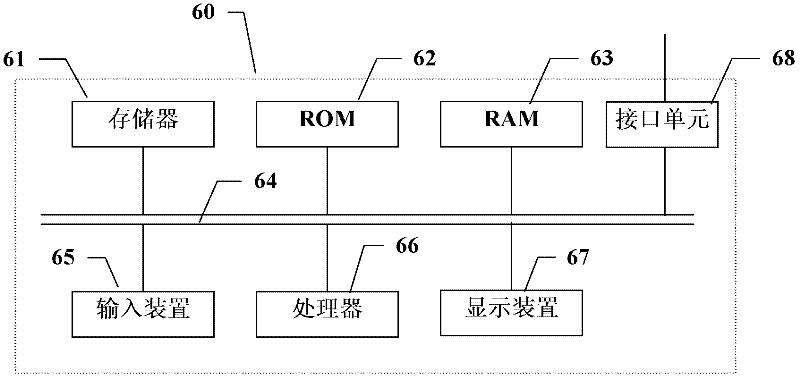

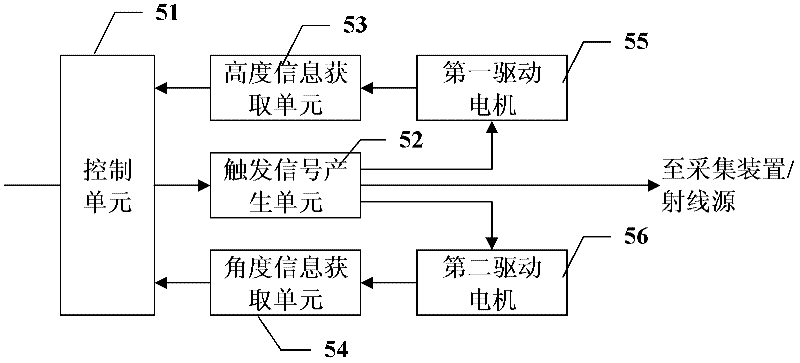

[0088] Such as figure 1 As shown, the inspection equipment according to this embodiment includes: a radiation source 10 that emits dual-energy X-rays for inspection, such as an X-ray machine; Detect the liquid object into the detection area, so that the radiation emitted by the ray source 10 can pass through the liquid object to be inspected; the detection and collection device 30 is a detector and a data collector with an overall module structure, which is used to detect the liquid object to be inspected. The dual-energy ray of the item obtains an analog signal, and converts the analog signal into a digital signal, thereby outputting the scanning data of the liquid item for high-energy X-rays and low-energy X-rays; the controller 50, which is used to control the synchronous work of various parts of the entire system ; and a computer data processor...

no. 2 approach

[0180] The above first embodiment describes the situation of detecting a single liquid item each time, and the operation process of simultaneously detecting multiple liquid items will be described in detail below with reference to FIGS. 15-18 . The difference between the second embodiment and the first embodiment is that because there are many liquid items, after the CT imaging is completed, the position of the imaging result displayed on the display corresponds to the position of the object on the carrying mechanism, so as to facilitate operation The officers figured out that the liquid item was a dangerous item. Figure 15A with Figure 15B A schematic diagram showing a reconstructed CT image in the case of detecting multiple liquid items according to the second embodiment of the present invention.

[0181] For example, the operator observes the object to be inspected on the carrying mechanism by looking down, which requires that the position of each object on the CT image ...

no. 3 approach

[0198] In order to further improve the detection efficiency and prevent the problem that the slender liquid objects to be inspected are directly placed on the carrying mechanism, which may cause instability during the inspection and affect the detection effect, the third embodiment proposes to place multiple objects in the divided bucket.

[0199] Therefore, the difference between the third embodiment and the second embodiment is that a divided bucket is used in the process of inspecting multiple objects. Attached below Figures 19-24 The specific operation process of the detection device according to this embodiment will be described in detail.

[0200] Figure 19 shows a side view of the divided barrel according to the present embodiment, Figure 20 shows a top view of the compartmented barrel, while Figure 21 A bottom view of the compartment bucket is shown.

[0201] Such as Figure 19 As shown, the compartment 70 includes a bottom and side walls coupled to the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com