Production method of instant nutritional paste food easy to mix

A kind of paste food, technology of production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

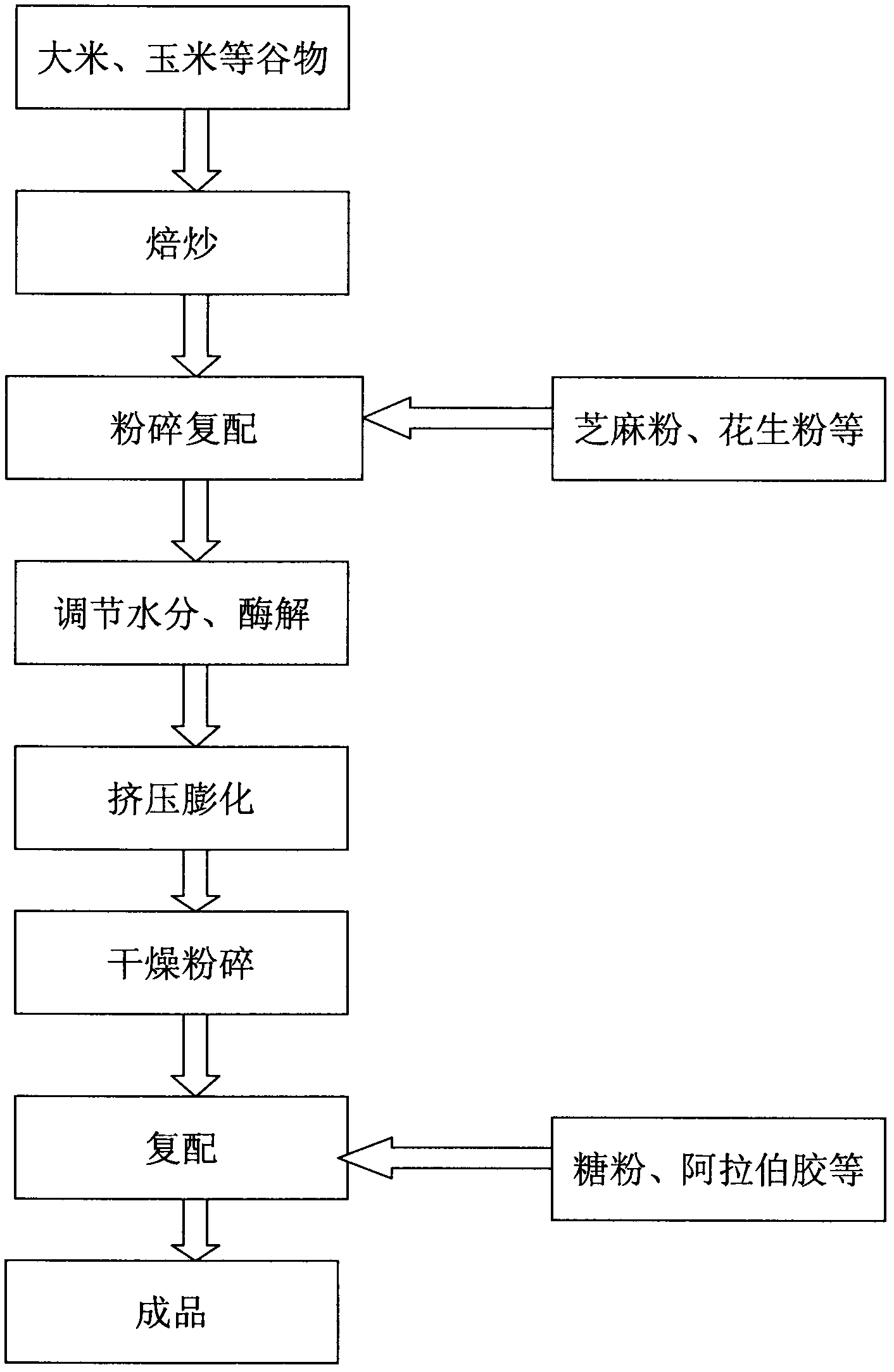

Image

Examples

Embodiment 1

[0019] Weigh 2Kg of barley and 2Kg of rice for roasting, then crush to 60 mesh, add 1Kg of peanut powder and 0.5Kg of sesame powder, and mix well. Use water containing medium-temperature α-amylase, adjust the moisture content to 20%, the enzyme content to 100u / g raw materials, mix well, and let stand for 4 hours, then extrude and expand on a twin-screw extruder, and the condition is set at a speed of 120r / min, outlet temperature 140°C. After the puffed material is extruded from the die hole, it is dried in a fluidized bed to a moisture content of 5-8%, and crushed to 60 mesh. In addition, 0.5kg of sucrose powder and 5g of gum arabic were weighed and mixed to obtain a ready-to-eat nutritional paste.

Embodiment 2

[0021] Weigh 2.5kg of corn, 2.5kg of millet, and 1Kg of soybeans, roast them separately, mix them well and crush them to 60 mesh, use water containing medium-temperature α-amylase, adjust the moisture content to 22%, and the enzyme content to 150u / g raw materials, mix Uniformity, and stand still for 4 hours, then carry out extrusion puffing on a twin-screw extruder, the conditions are set at a rotational speed of 120r / min and an outlet temperature of 140°C. After the puffed material is extruded from the die hole, it is dried in a fluidized bed to a moisture content of 5-8%, and crushed to 60 mesh. In addition, 0.6kg of sucrose powder and 6g of gum arabic were weighed and mixed to obtain a ready-to-eat nutritional paste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com