Hot melt adhesive particle production line

A production line and hot-melt adhesive technology, applied in the equipment field of hot-melt rubber products, can solve the problems of high labor intensity of workers, no market competitive advantage of products, and low degree of automation, so as to reduce production and operation costs and improve market share. Competitive advantage, the effect of low labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

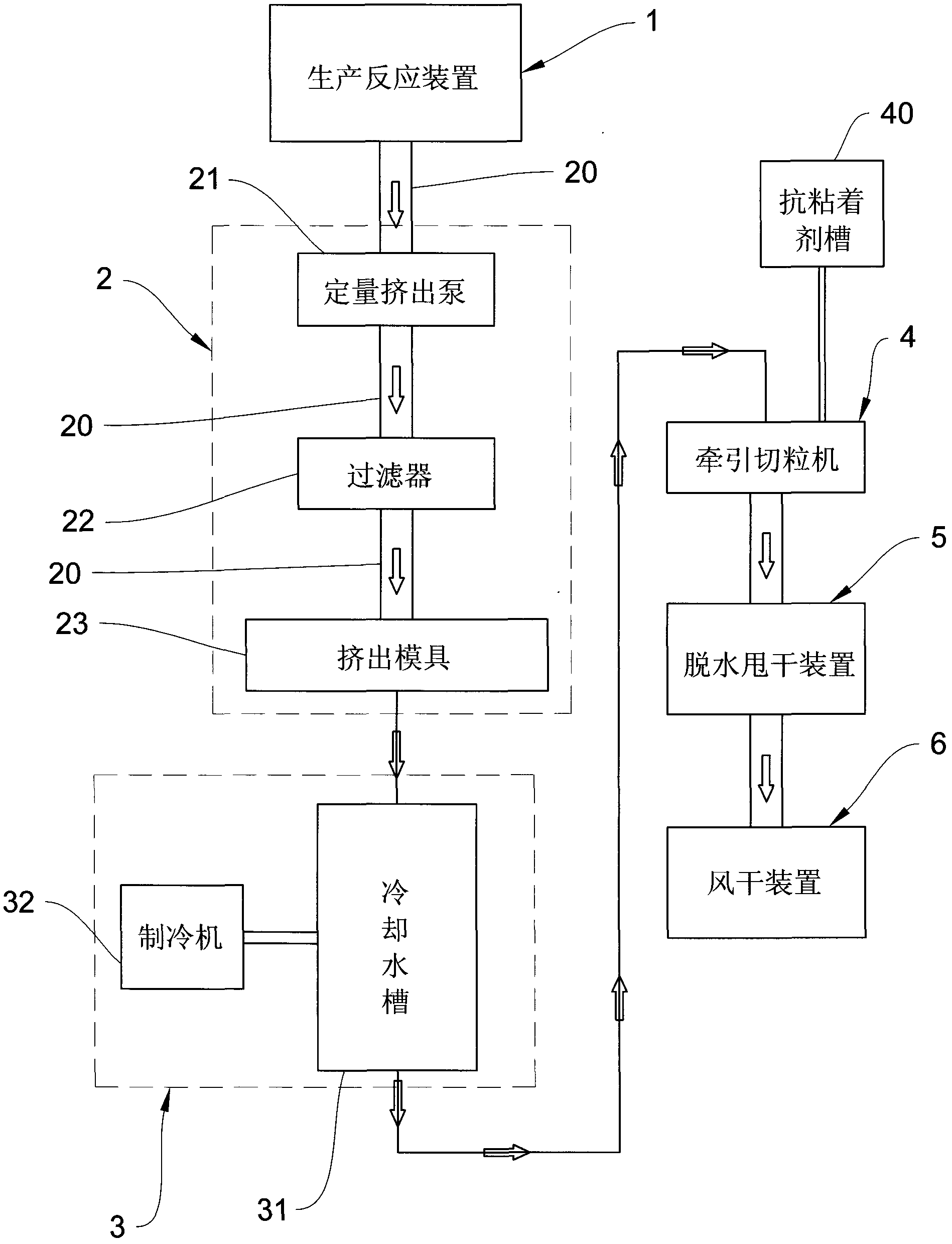

[0017] Such as figure 1 As shown, a kind of hot-melt glue particle production line of the present invention comprises production reaction device 1, extruding device 2, cooling device 3, traction pelletizer 4, dehydration drying device 5 and air-drying device 6, wherein

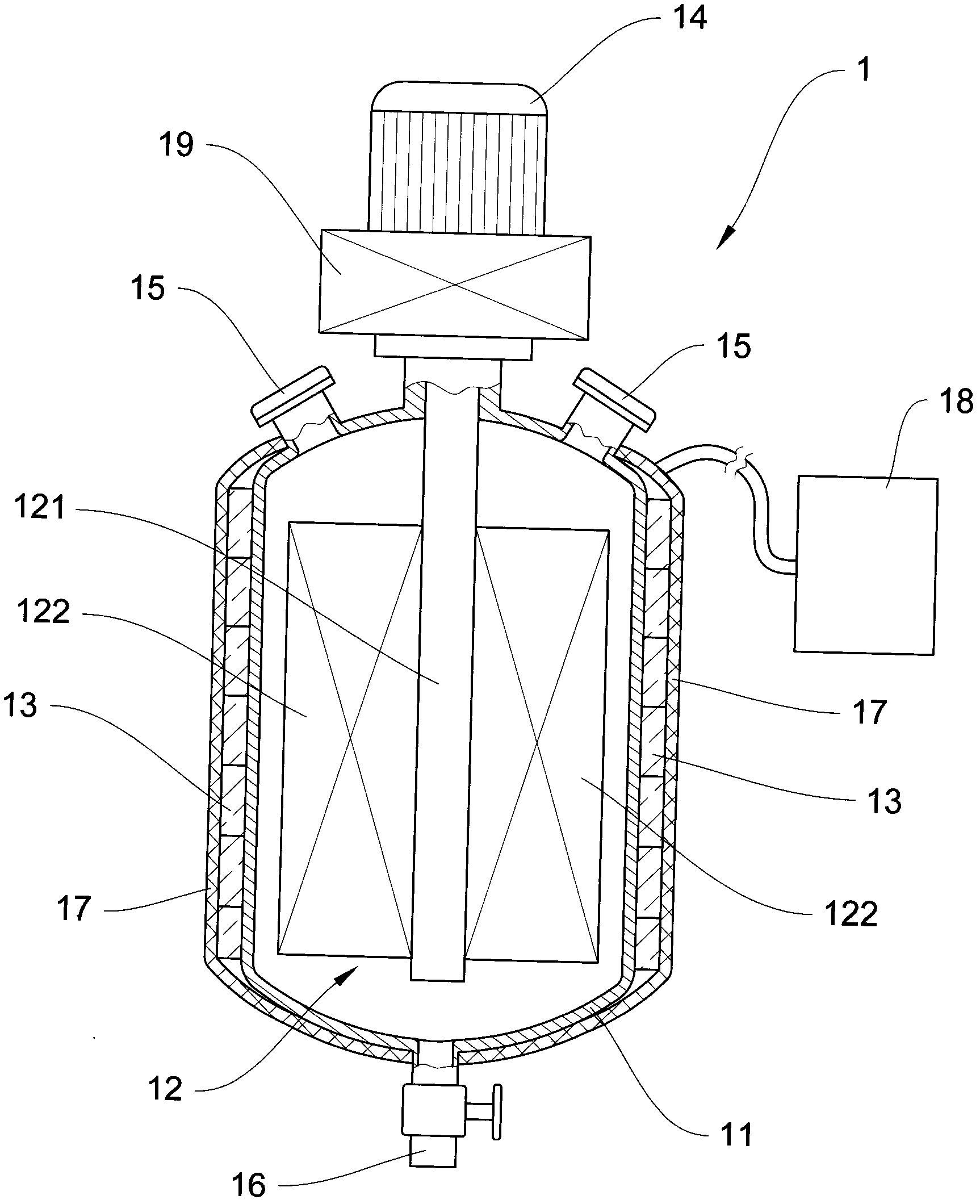

[0018] The production reaction device 1 is mainly used for melting and stirring uniformly the raw materials for producing hot-melt rubber particles before extrusion. Such as figure 2 As shown, the production reaction device 1 includes a reaction vessel 11, a stirrer 12, a far-infrared heating mechanism 13 and a stirring drive motor 14, wherein the reaction vessel 11 is in most cases all made into a container body of a fully enclosed structure, so as to During the production process, the hot melt adhesive products will not directly emit various unpleasant colloidal odors to the workshop or nature, so as to protect the environment and ensure the safety of workshop production. another example figure 2 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com