Rotational moulding machine

A molding machine and heating chamber technology, which is applied in the direction of coating, hollow objects, household appliances, etc., can solve the problem that the mold cannot be effectively guaranteed to be heated quickly and evenly, and the quality accuracy of the product surface texture is not high, and it is difficult to realize the mold heating and other problems to achieve the effect of ensuring rapid heating, compact structure and easy improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

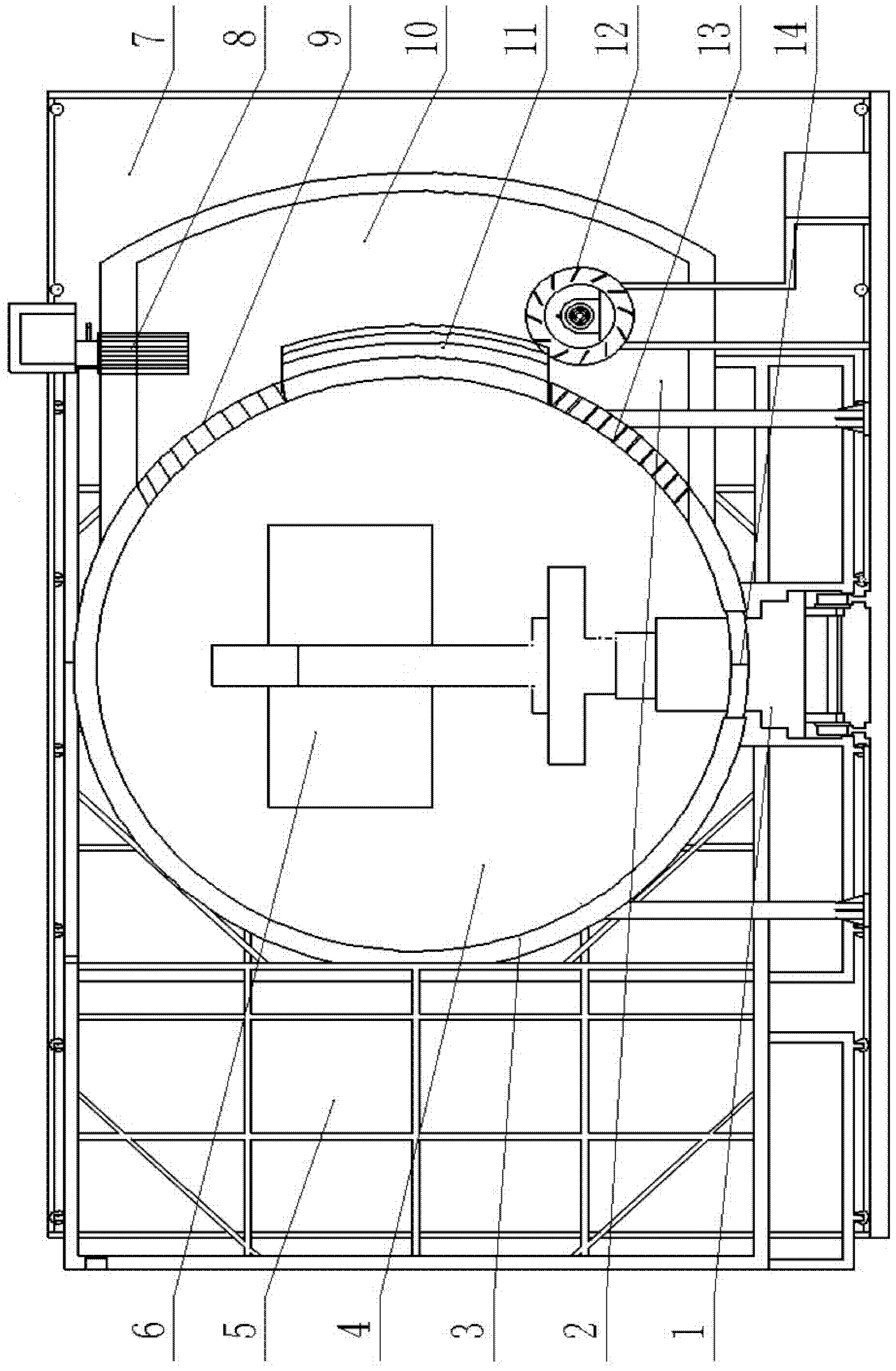

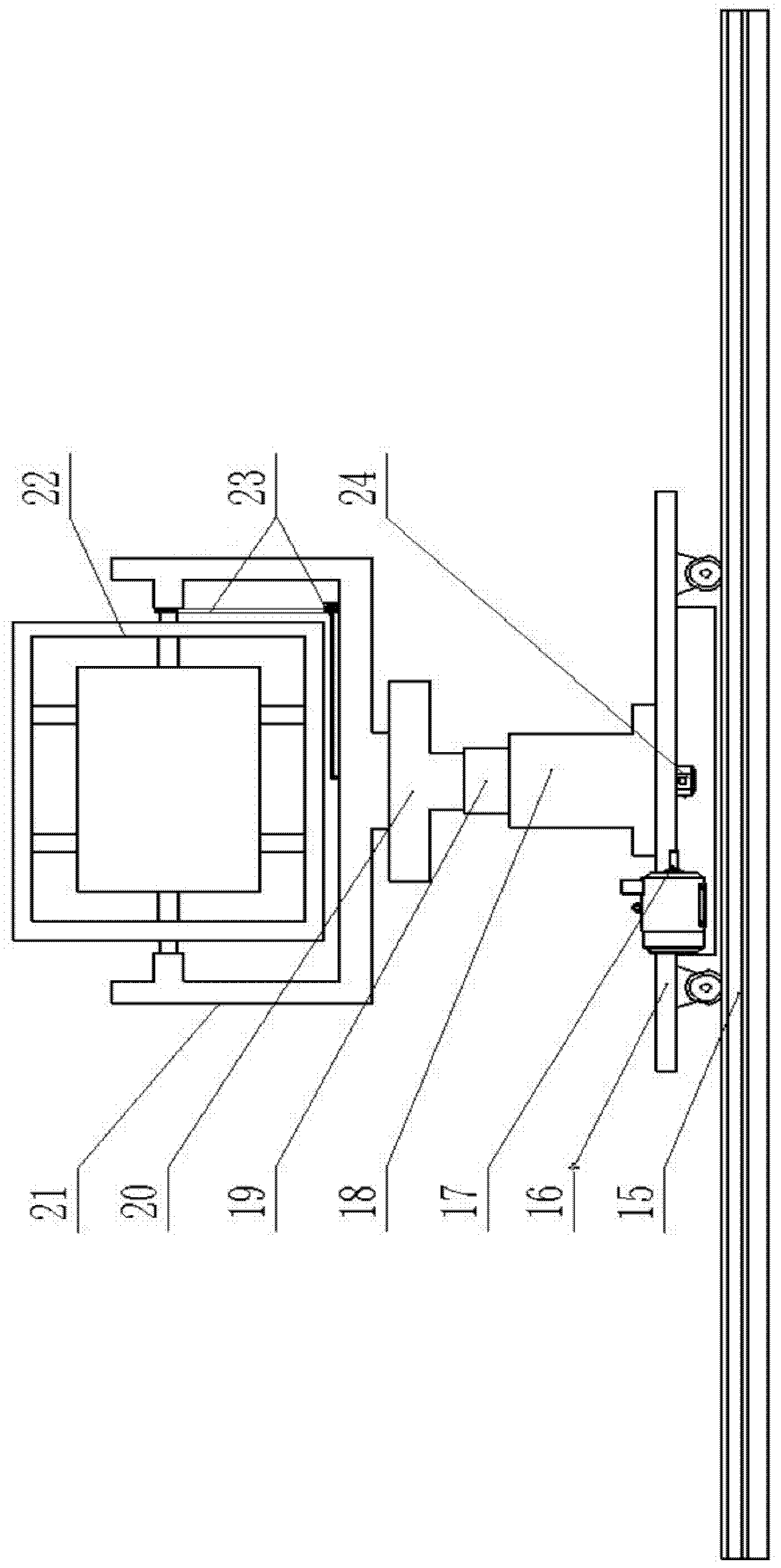

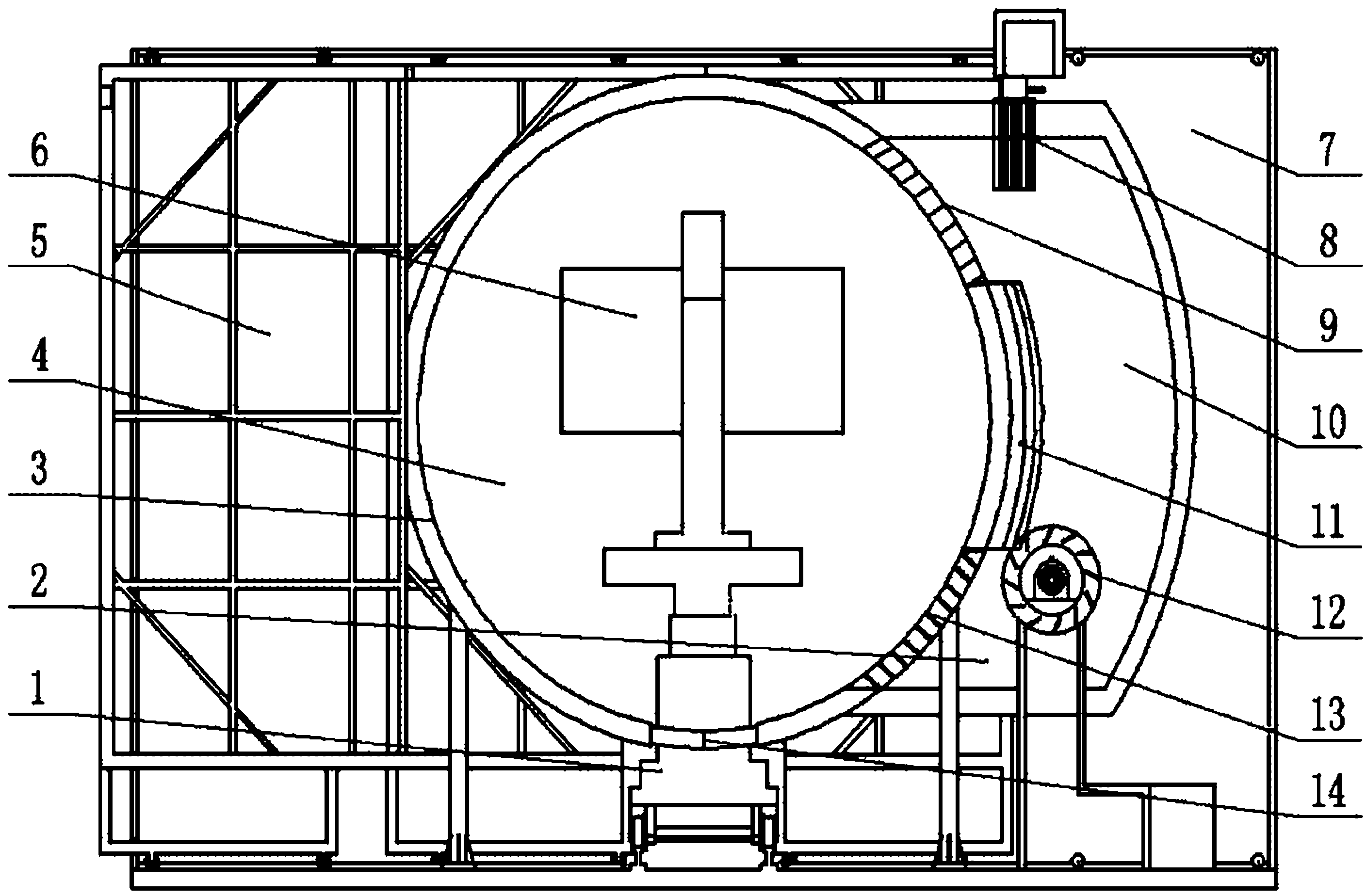

[0014] A kind of rotational molding machine of the present invention, as figure 1 with figure 2 As shown, it mainly includes a support system 1, a heating system 2, a heating chamber 4, and a track 15. The heating chamber 4 is surrounded by an oven wall 3, a front side door 5, a rear side door 7, and a bottom baffle 14. Located at the bottom of the oven wall 3, when the bracket system 1 moves into the heating chamber 4, it blocks the bottom opening of the oven wall 3, and the front side door 5 and the rear side door 7 can be opened to facilitate the bracket system 1 to move in and out of the heating chamber 4. The bracket system 1 includes Vehicle frame 16, driving motor 17, lifting column one 18, lifting column two 19, rotating disk 20, mold frame one 21, mold frame two 22, transmission shaft 23, rotating motor 24, mold 6 is installed on the mold frame two 22, Die frame two 22 is installed on mold frame one 21, and mold frame one is installed on the rotating disc 20. The ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com