Assembled continuous lifting jack for finish-rolling threaded steel bar vertical columns

A technology for finishing rolling threads and jacks, which is applied in hoisting devices, buildings, building structures, etc., can solve problems such as inability to universally stretch prestressed steel strands, expensive investment in hoisting equipment, and inability to achieve multiple uses for one machine. The effect of light weight, good strength and rigidity, and low cost of equipment modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

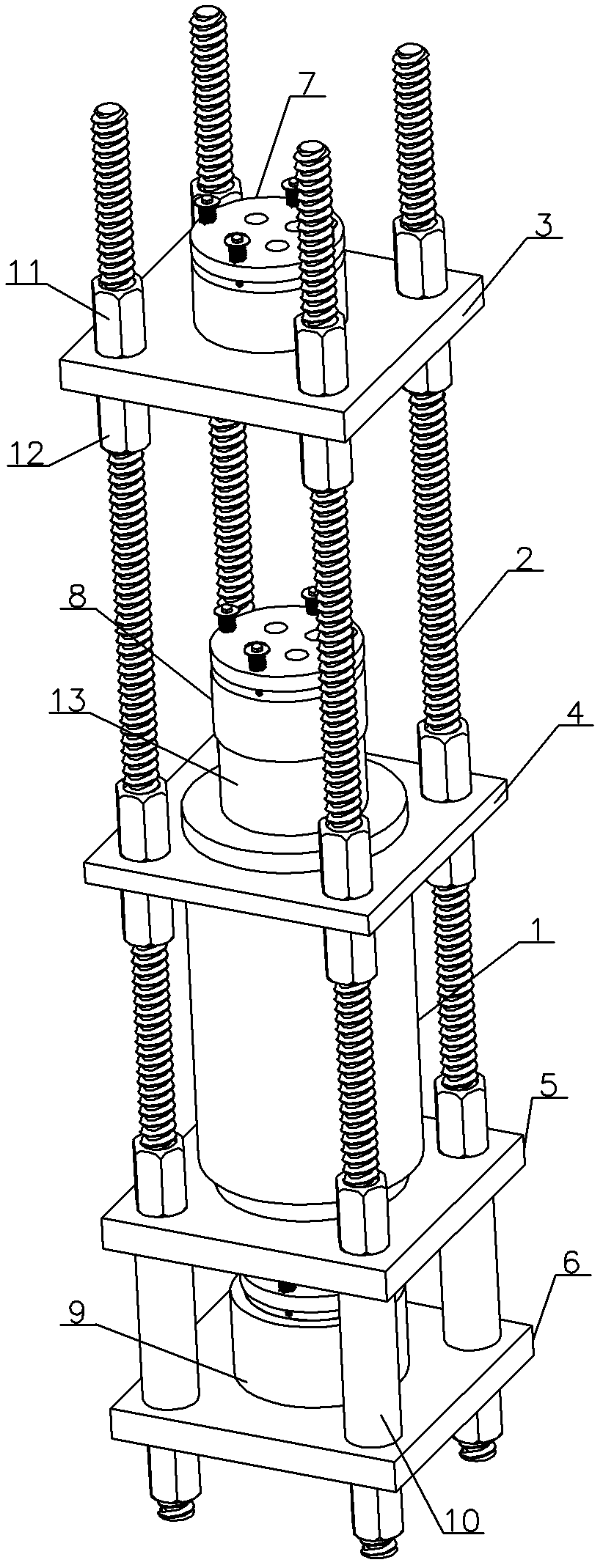

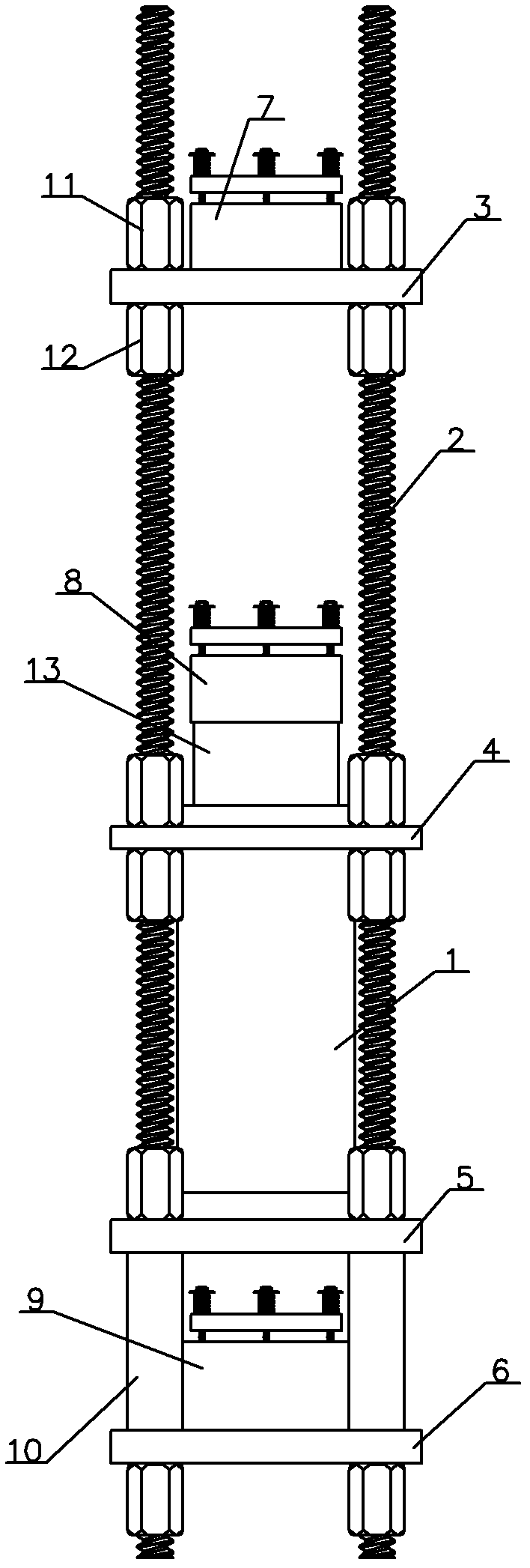

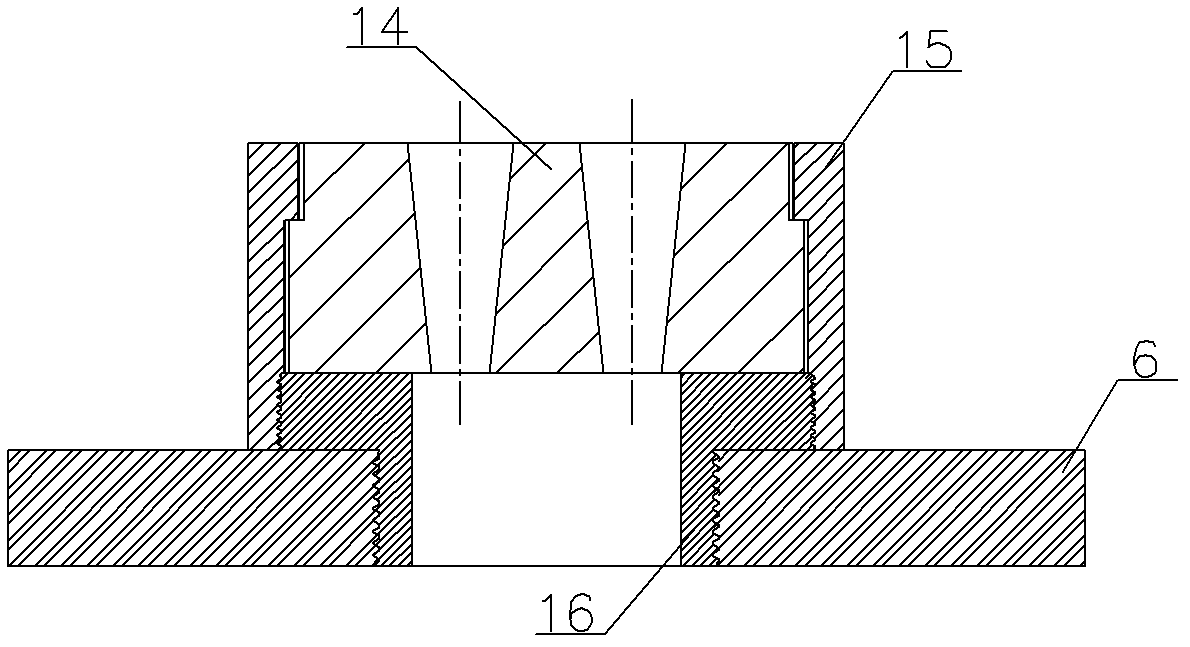

[0018] The fine-rolled threaded steel column assembled continuous lifting jack includes a hydraulic through-hole jack, a column support frame, an upper tool anchor, a lower tool anchor and a guide safety anchor. The hydraulic jack adopts ordinary prestressed tension jack; the column support frame is composed of fine-rolled threaded steel bars, platform steel plates, and threaded sleeves and nuts matched with the finished-rolled threaded steel bars. The platform steel plates are divided into lower tool anchor steel plates, The pressure-bearing steel plate at the bottom of the jack, the clamping plate at the end of the cylinder body of the jack, and the guide safety anchor fix the steel plate; the anchors for the upper tool anchor, the lower tool anchor and the guide safety anchor for anchoring the hoisting steel strand use a strip steel hinge clip top pressure spring The automatic tool anchor, and the elastic coefficient of the pressure spring of the steel strand clip of the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com