Method for directly leaching zinc and recovering gallium, germanium and indium from zinc sulfide concentrate

A zinc sulfide concentrate and leaching technology, applied in the field of hydrometallurgy, can solve the problems of large amount of leaching slag and difficult separation, and achieve the effect of less leaching slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

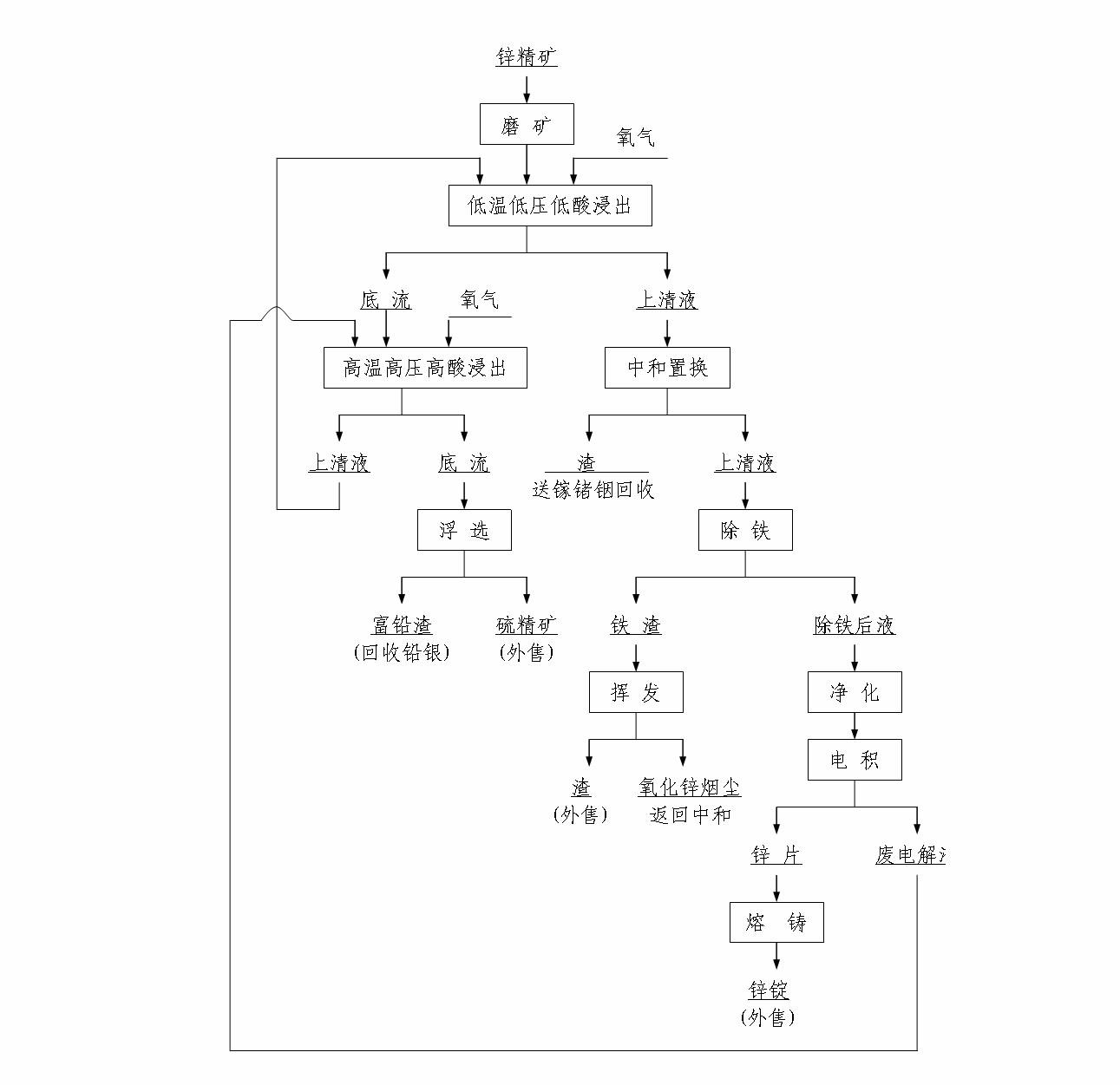

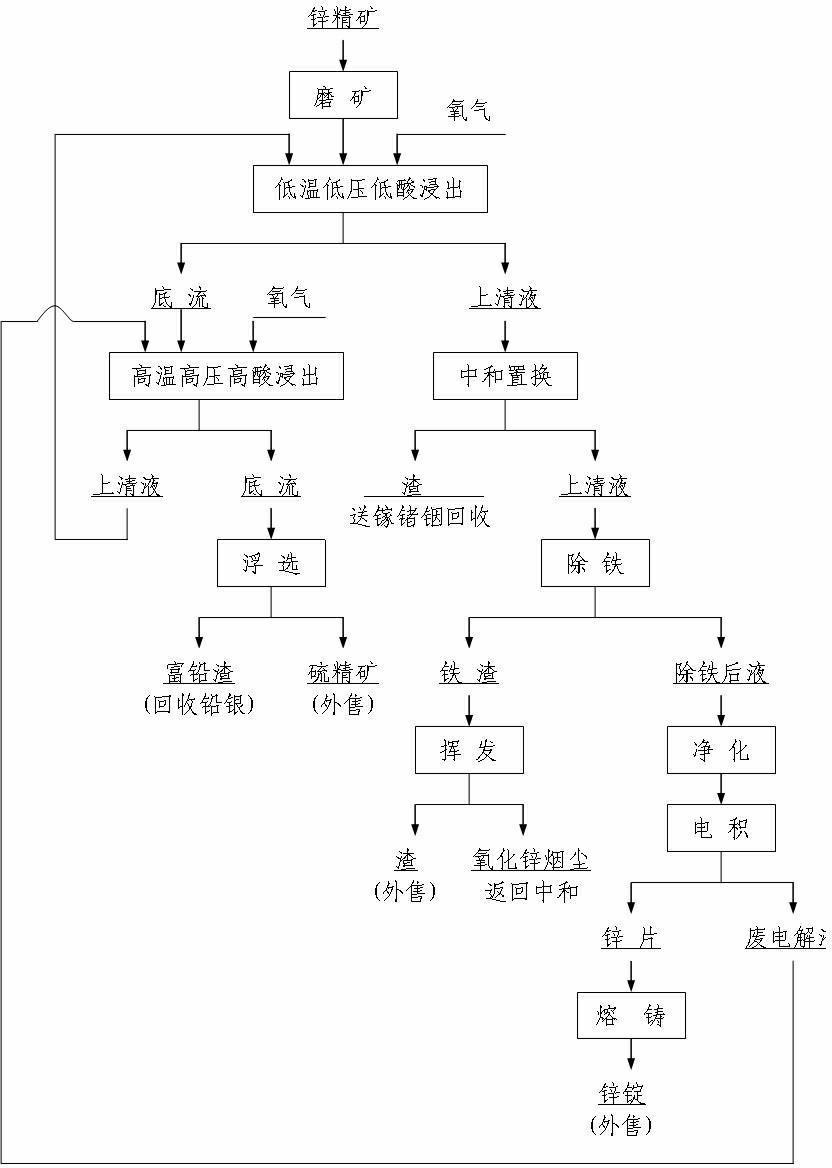

[0031] From figure 1 Can find out that technological process of the present invention, its concrete implementation steps are:

[0032] (1) After the zinc concentrate is ground, the particle size is about 25-40 μm. It will be pumped into the first-stage reactor, and oxygen with a concentration of more than 98% will be introduced. It will be leached with low-temperature, low-pressure and low-acid, and the temperature will be within the range of 105-120°C. The pressure is in the range of 200-350kPa, and the acidity is in the range of 10-20g / l. The temperature used in this embodiment is 110° C., the pressure is 300 kPa, and the acidity is 15 g / l. In this way, the sulfur in the zinc sulfide is oxidized to elemental sulfur, and the zinc becomes soluble zinc sulfate. After the leached pulp is cooled and pressure-reduced in the flash tank, it is sent to a thickener for separation, and the supernatant of the first stage is leached into the zinc sulfate solution.

[0033] (2) Pump th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com