Production method for pure cotton single direction wet guiding functional nonwovens

A non-woven, functional technology, used in textiles and papermaking, fiber processing, plant fibers, etc., can solve the problems of difficult droplet ordering, loss of water repellency on one side of non-woven fabrics, etc. The effect of large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

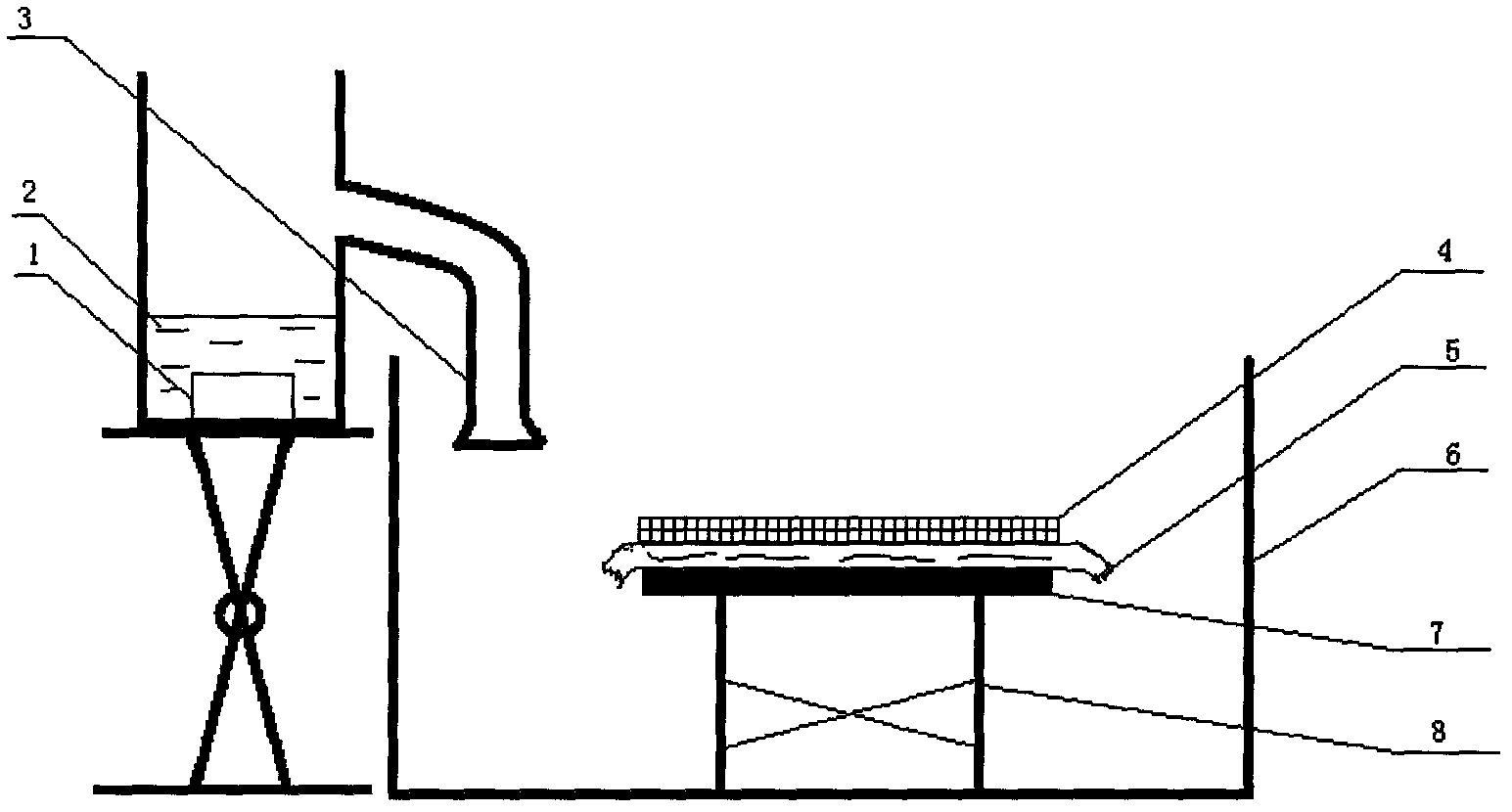

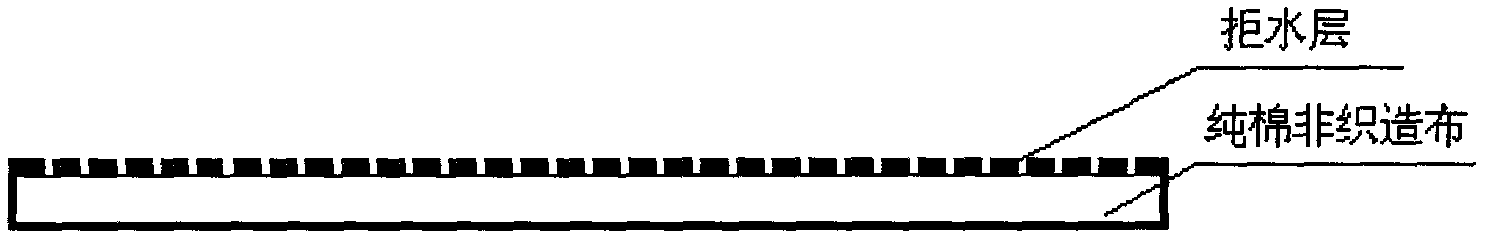

[0033] A method for preparing pure cotton unidirectional moisture-conducting functional nonwoven fabric, characterized in that: the preparation method of pure cotton unidirectional moisture-conducting functional nonwoven fabric is as follows:

[0034] A Preparation of fluorine-containing water-repellent finishing agent solution 2

[0035] Dissolve the fluorine-containing water-repellent finishing agent in distilled water, and stir until it is uniformly dispersed to prepare a mixed solution with a mass fraction of the fluorine-containing water-repellent finish agent of 1% to 30%, and then add penetrant to the mixed solution, the penetrant The mass is 1 to 3 times that of the fluorine-containing water-repellent finishing agent, and the type is sodium α-alkenyl sulfonate or fatty alcohol polyoxyethylene ether or sulfated castor oil or sodium alkyl sulfonate or sodium alkylbenzene sulfonate or sodium alkylsulfate, sodium secondary alkylsulfonate, sodium secondary alkylsulfate, sod...

Embodiment 1

[0043] A Dissolve 1g of AG-XF fluorine-containing water repellent in 99g of distilled water, stir well until it is evenly dispersed, and make AG-XF

[0044] A mixed solution with a mass fraction of fluorine-containing water-repellent agent of 1%, and then 1 g of sodium α-olefin sulfonate penetrant was added to the mixed solution to obtain an AG-XF fluorine-containing water-repellent solution to be ultrasonically atomized.

[0045] B Place the ultrasonic nebulizer in the AG-XF fluorine-containing water repellent solution for ultrasonic atomization to prepare AG-XF fluorine-containing water repellent atomized microbeads, the particle size of which is 10 μm.

[0046] C Place the pure cotton non-woven fabric on a glass plate, lay a 20-mesh screen on the upper surface of the pure cotton non-woven fabric, and place it in a container through a bracket to make the pure cotton non-woven fabric The woven cloth is in the middle of the container, and the AG-XF fluorine-containing water-re...

Embodiment 2

[0048] A Dissolve 1g of AG-XF fluorine-containing water repellent in 99g of distilled water, stir well until it is uniformly dispersed, and make a mixed solution of AG-XF fluorine-containing water repellent with a mass fraction of 1%, and then add 2g of fat to the mixed solution Alcohol polyoxyethylene ether to obtain AG-XF fluorine-containing repellent solution to be ultrasonically atomized.

[0049] B Place the ultrasonic nebulizer in the AG-XF fluorine-containing water repellent solution for ultrasonic atomization to prepare AG-XF fluorine-containing water repellent atomized microbeads, the particle size of which is 10 μm.

[0050] C Place the pure cotton non-woven fabric on a glass plate, lay a 30-mesh screen on the upper surface of the pure cotton non-woven fabric, and place it in a container through a bracket to make the pure cotton non-woven fabric The cotton non-woven fabric is in the middle of the container, and the AG-XF fluorine-containing water repellent atomized b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com