Yarn dyeing method

A dyeing method and yarn dyeing technology, applied in the field of textile printing and dyeing, can solve the problems of high dosage of fixing agent, staining and high dosage of reactive dyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

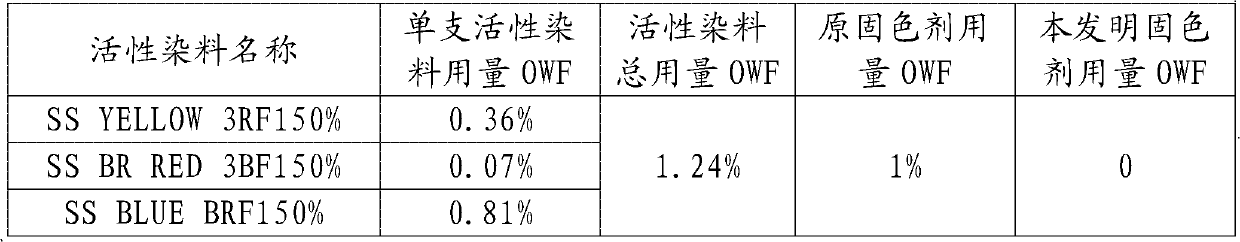

Image

Examples

example 1

[0023] Example 1: 80s / 2 green plain weave

[0024] 1. Process flow:

[0025] Yarn pretreatment→dyeing with reactive dyes→fixation treatment (washing or pickling, fixation, softening, dehydration, drying)→post-treatment (warping→sizing→weaving→singeing→desizing→caustic soda mercerizing→ Liquid ammonia mercerizing→setting→preshrinking→finished product inspection→color fastness test).

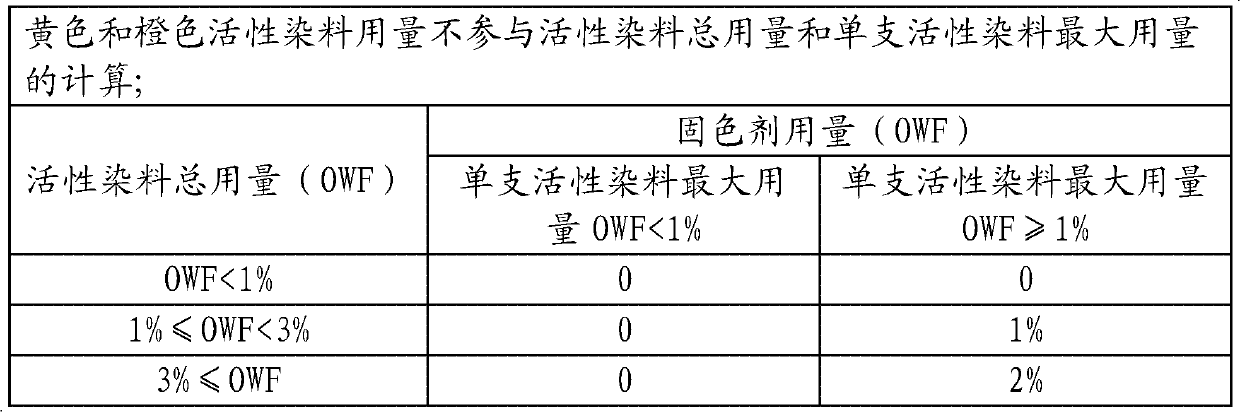

[0026] 2. Reactive dye combination and fixing agent dosage

[0027]

[0028] 3. Fixing process:

[0029] Washed cotton bobbins after dyeing

[0030] ①The amount of color fixing agent DM-2518 is 1%, and it is treated in the dyeing vat for 30 minutes at 50°C and the bath ratio is 1:10.

[0031] ②No color fixation

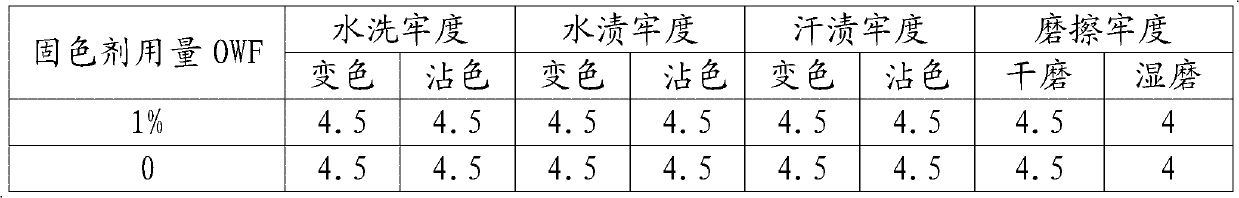

[0032] 4. Color fastness test of finished fabric:

[0033]

[0034] The test method for washing fastness is AATCC 135-2004, the test method for water fastness is AATCC 107-2009, the test method for perspiration fastness is AATCC 15-2009, and the test method for rubbing fastnes...

example 2

[0036] Example 2: 80s / 2 orange twill

[0037] 1. Process flow:

[0038] Yarn pretreatment→dyeing with reactive dyes→fixation treatment (washing or pickling, fixation, softening, dehydration, drying)→post-treatment (warping→sizing→weaving→singeing→desizing→caustic soda mercerizing→ Liquid ammonia mercerizing→setting→preshrinking→finished product inspection→color fastness test).

[0039] 2. Reactive dye combination and fixing agent dosage:

[0040]

[0041] 3. Fixing process:

[0042] Washed cotton bobbins after dyeing;

[0043] ① The amount of color fixing agent DM-2518 is 2%, and it is treated in the dyeing vat for 30 minutes at 50°C and the bath ratio is 1:10.

[0044] ② The amount of color fixing agent DM-2518 is 1%, and it is treated in the dyeing vat for 30 minutes at 50°C and the bath ratio is 1:10;

[0045] 4. Color fastness test of finished fabric:

[0046]

[0047] The test method for washing fastness is AATCC 135-2004, the test method for water fastness is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com