Throat-type inlet manifold of electrical control fuel jet-type internal combustion engine

A fuel injection and intake manifold technology, applied in the direction of combustion air/combustion-air treatment, mechanical equipment, engine components, etc., can solve the problems of limited improvement of mixing efficiency, increase of overall structure volume, and increase of mixing time, etc. Achieve the effects of reducing harmful gas emissions, saving fuel and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

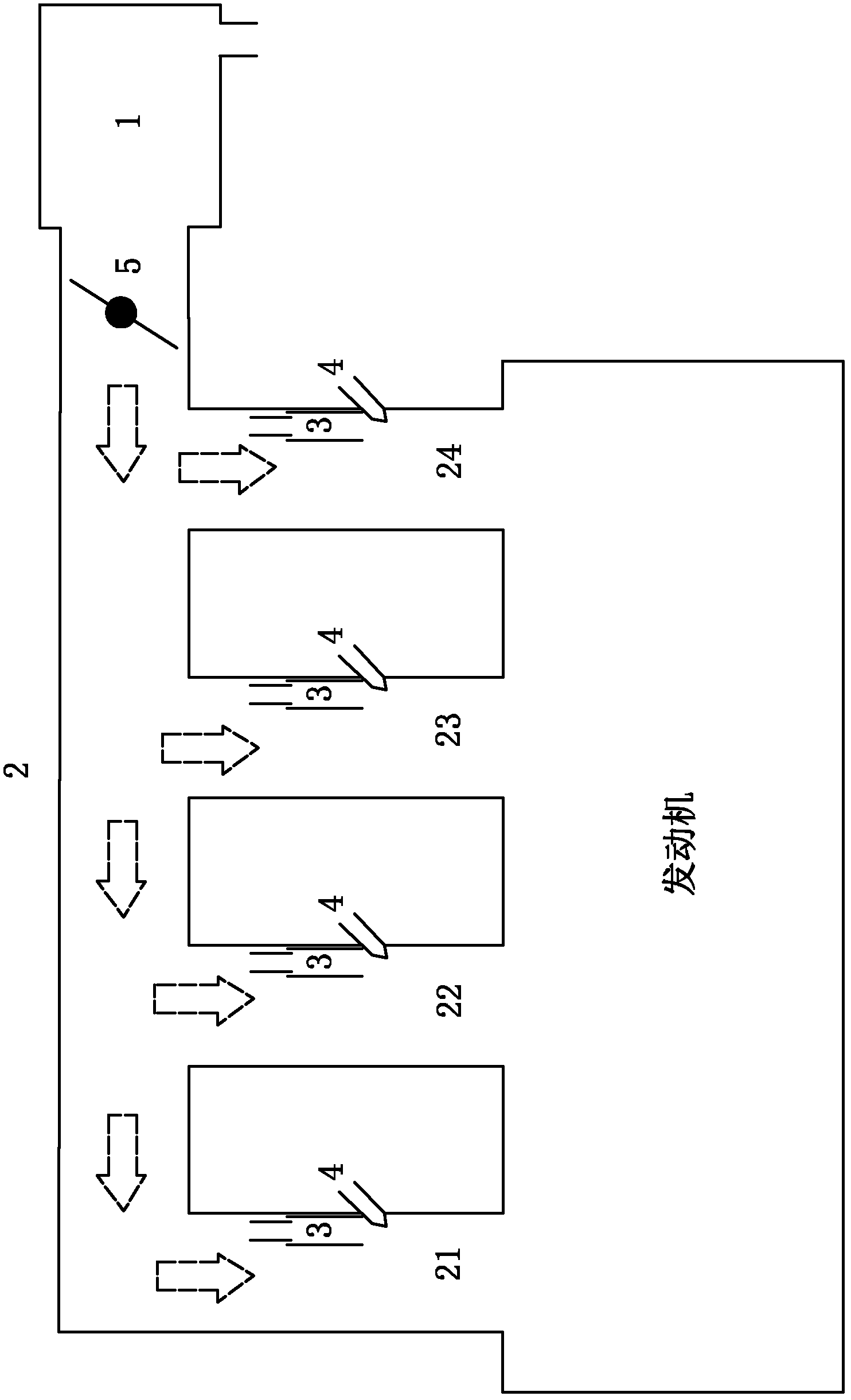

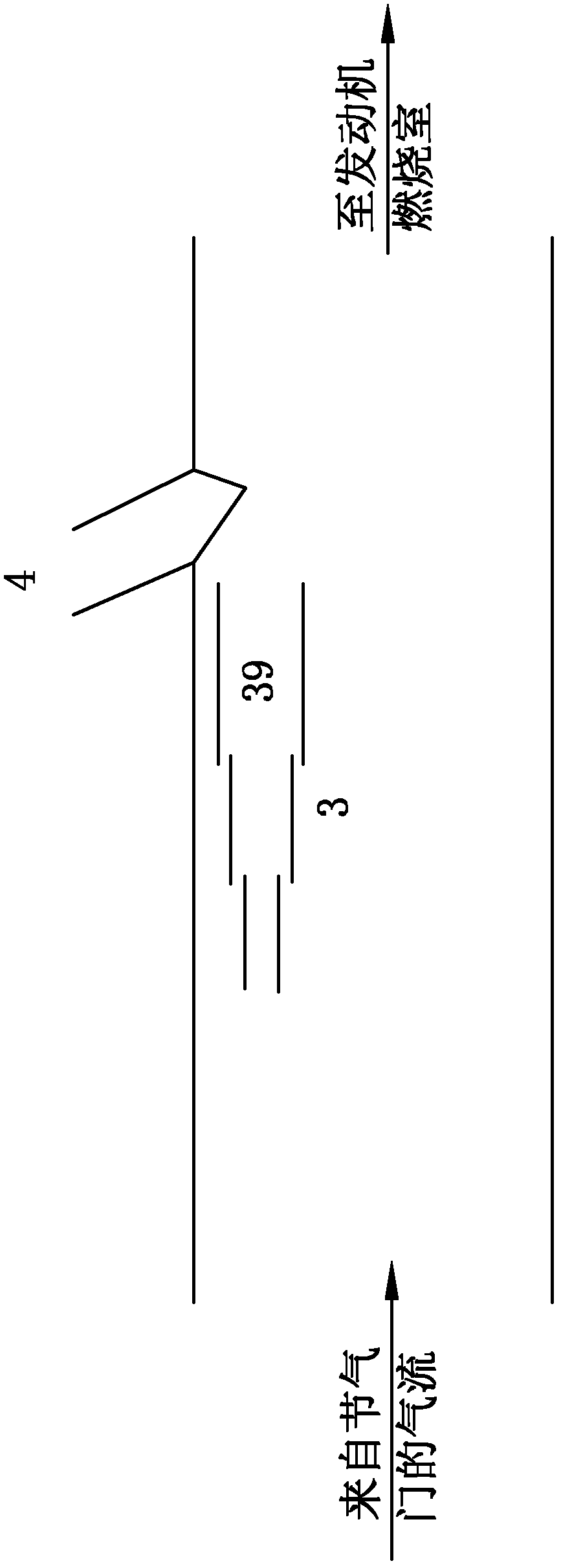

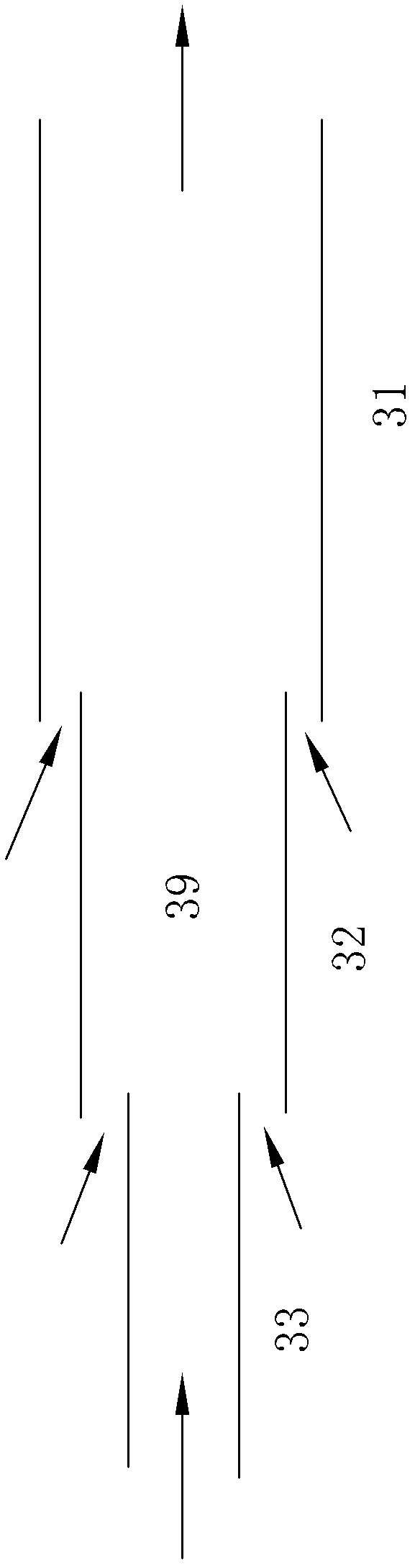

[0031] The electronically controlled fuel injection type internal combustion engine throat type intake manifold of the present invention, as attached figure 1 , attached figure 2 As shown, it includes a body 2, which is provided with several passages 21, 22, 23, 24 communicating with the combustion chamber of the engine, and an oil injector 4 is arranged in the passages 21, 22, 23, 24, and each passage One or more throats 3 are also provided, and the throats 3 have diversion holes 39 , the diversion holes 31 are arranged along the air intake direction and the outlets at the front end thereof are close to the injection ports of the fuel injection nozzles 4 . The cross-section of the diversion hole 31 can be circular, elliptical or other shapes, and the diameter of the outlet end of the diversion hole 31 is larger than the diameter of the inlet end.

[0032] When there are multiple throats 3 , the multiple throats 3 are arranged in a fan shape and surround the fuel injection n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com