Blade structure for centrifugal fans

A technology of blade structure and centrifugal fan, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the problems of failure to achieve, affect the efficiency of the fan, and the installation angle destroys the uniform arrangement of the circumferential angle of the blade, so as to reduce the The effect of airflow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

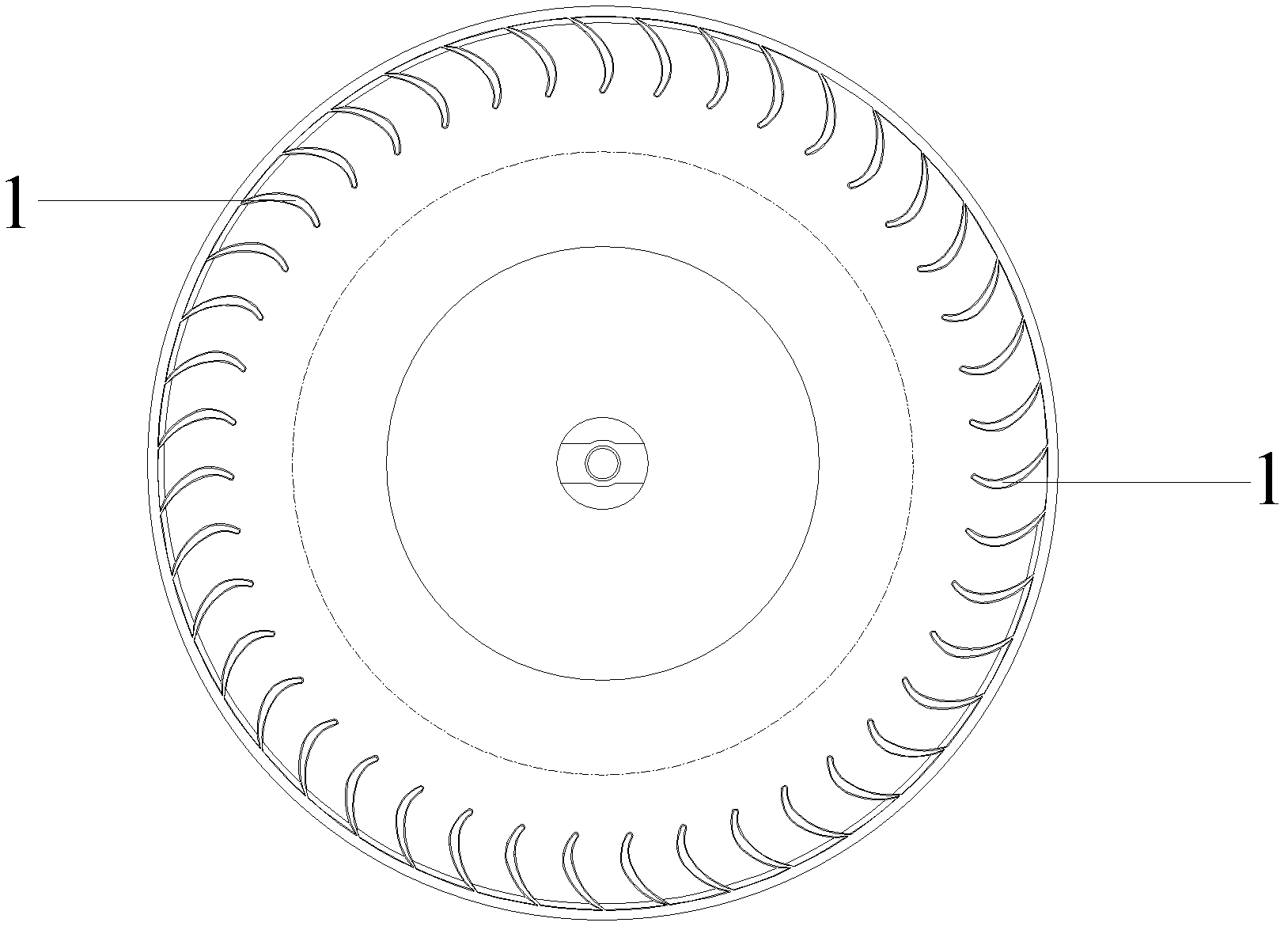

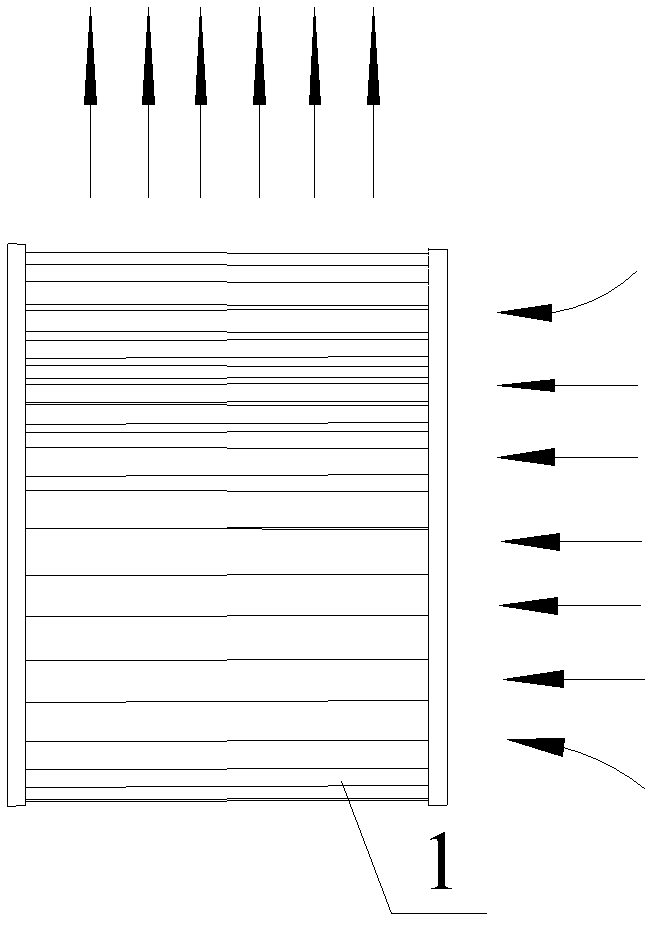

[0023] See Figure 5 and Figure 6 , Figure 5 It is a structural schematic diagram of the blade structure of the centrifugal fan in Embodiment 1 of the present invention; Figure 6 for Figure 5 A schematic diagram of the blade structure of the centrifugal fan in Example 1.

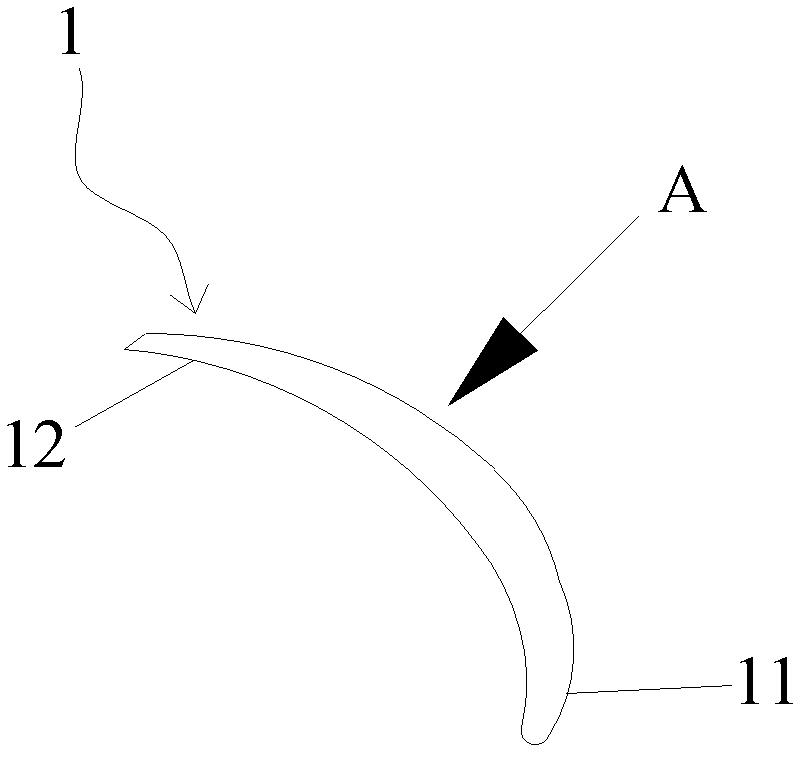

[0024] The blade structure of the centrifugal fan provided in this embodiment includes a blade leading edge 12 and a blade trailing edge 11. The blade trailing edge 11 is a sawtooth structure, and the sawtooth structure includes a tooth groove 111 and a crest 112. The teeth in the sawtooth structure of the blade trailing edge 11 are The ratio of the height a of the groove 111 to the width of the blade 1 is 25%; the angle a of the tooth groove 111 in the sawtooth structure of the blade trailing edge 11 is 60°; the outer surface of the side where the blade trailing edge 11 is located is provided with a small pit 113 ; The shape of the small pit 113 is one or more of circular, square or triangular. The...

Embodiment 2

[0028] The blade structure of the centrifugal fan provided by this embodiment includes a blade leading edge and a blade trailing edge, the blade trailing edge is a sawtooth structure, and the sawtooth structure includes tooth grooves and tooth tops, and the height of the tooth grooves in the sawtooth structure of the blade trailing edge is the same as that of the blade. The width ratio is 30%; the angle a of the tooth groove in the sawtooth structure of the trailing edge of the blade is 90°; the outer surface of the side where the trailing edge of the blade is located is provided with small pits; the shape of the small pits is circular, square or triangular one or more of. In the sawtooth structure, the tooth top is in the shape of a pointed tooth top.

[0029] The leading edge of the blade is a sawtooth structure, and the sawtooth structure includes tooth grooves and tooth tops. The ratio of the height of the tooth grooves in the sawtooth structure of the blade leading edge t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com