Automatic electronic microporous leakage detecting machine for flexible bag

A leak detection machine and automatic technology, which is applied in the application of electric devices to test the fluid tightness, etc., can solve the problems of secondary pollution of the liquid medicine in the soft bag, rupture of the diaphragm in the bag cavity, secondary pollution of the liquid medicine, etc., and achieve repeated detection The effect of high precision, high accuracy, and high leak detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

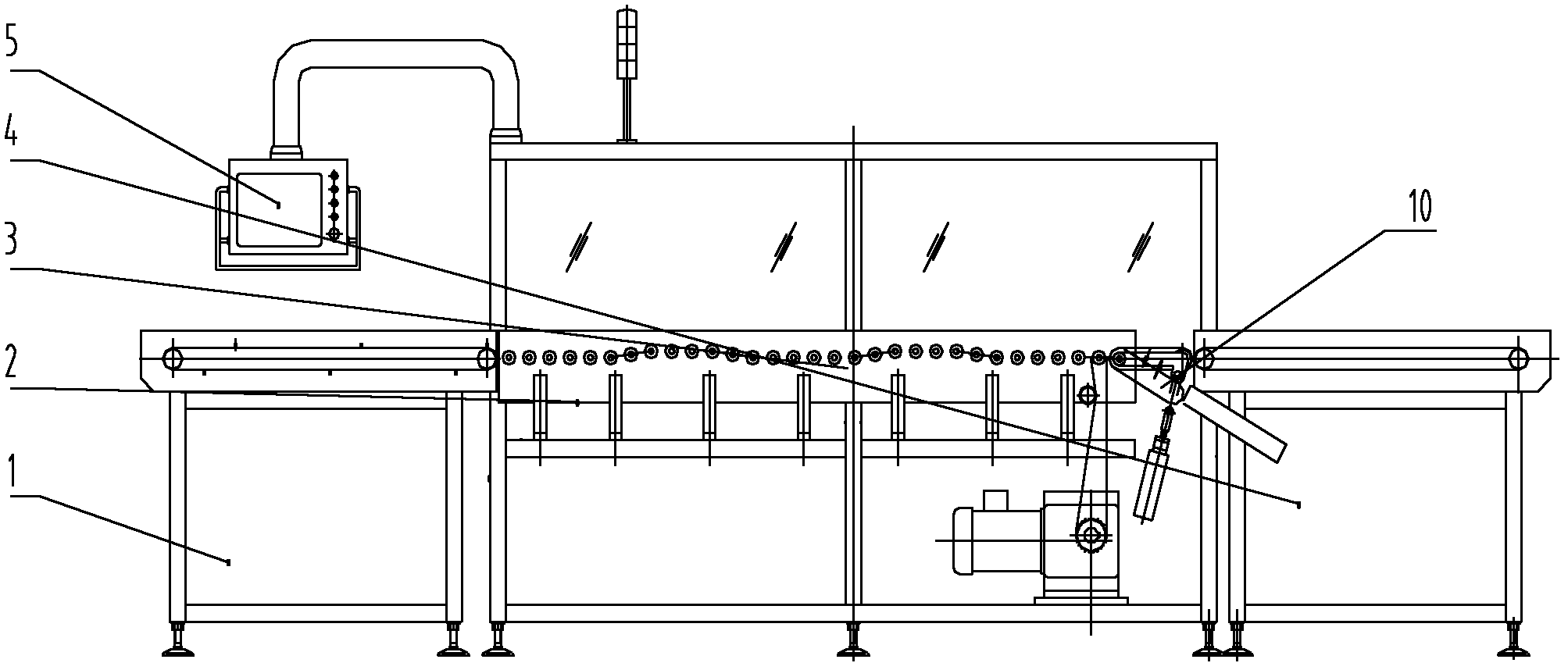

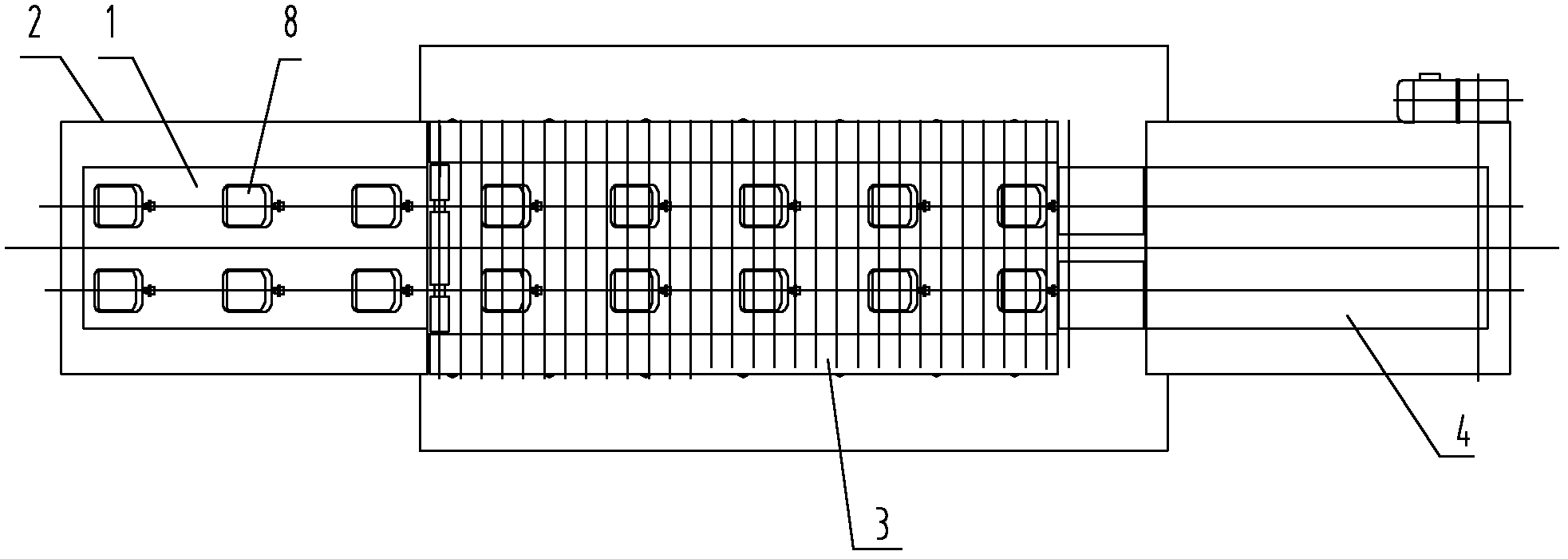

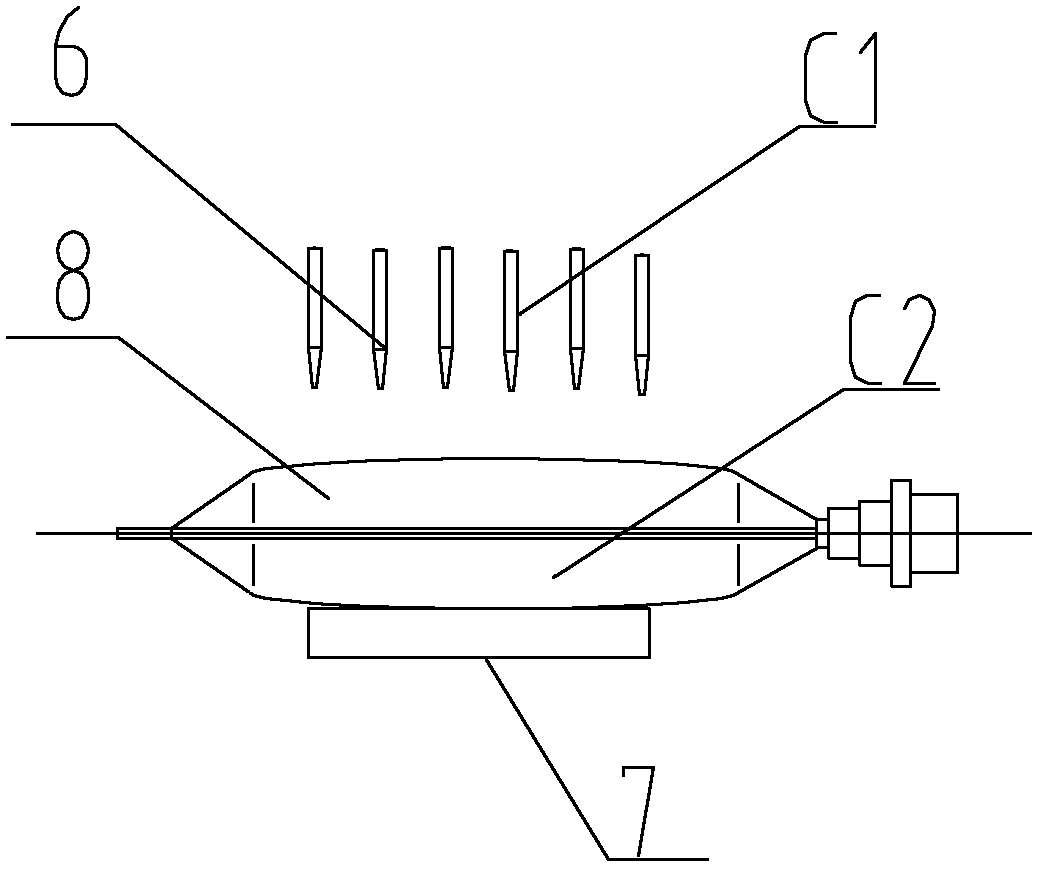

[0026] see figure 1 , figure 2 and image 3 , the front and rear of the frame 2 are respectively provided with a bag-feeding track 1, a waste rejecting mechanism 10, a bag-out track 4, a high-frequency and high-voltage power supply and an electrical control box 5, and the rack 2 is provided with a bag-feeding track 1 and a rejecting track 1. The detection channel 3 between the waste mechanism 10, the bag-in track 1, the detection channel 3 and the bag-out track 4 are conveyed in double rows at equal intervals, and the detection channel 3 is conveyed by rollers, and multiple detection stations are arranged on the detection channel 3 , can detect different positions according to the requirements of different users. Each detection station is equipped with a set of high-frequency and high-voltage leak detection devices. The receiving pole 7 connected to the receiving end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com