Probability distribution test device for collision by abrasive particles in solid and liquid two-phase flow on wall surface at different positions

A probability distribution and testing device technology, applied in the direction of fluid pressure measurement, analysis of materials, and instruments by changing ohmic resistance, can solve the problem of inability to truly test the impact of abrasive particles on the wall, and achieve the effect of simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

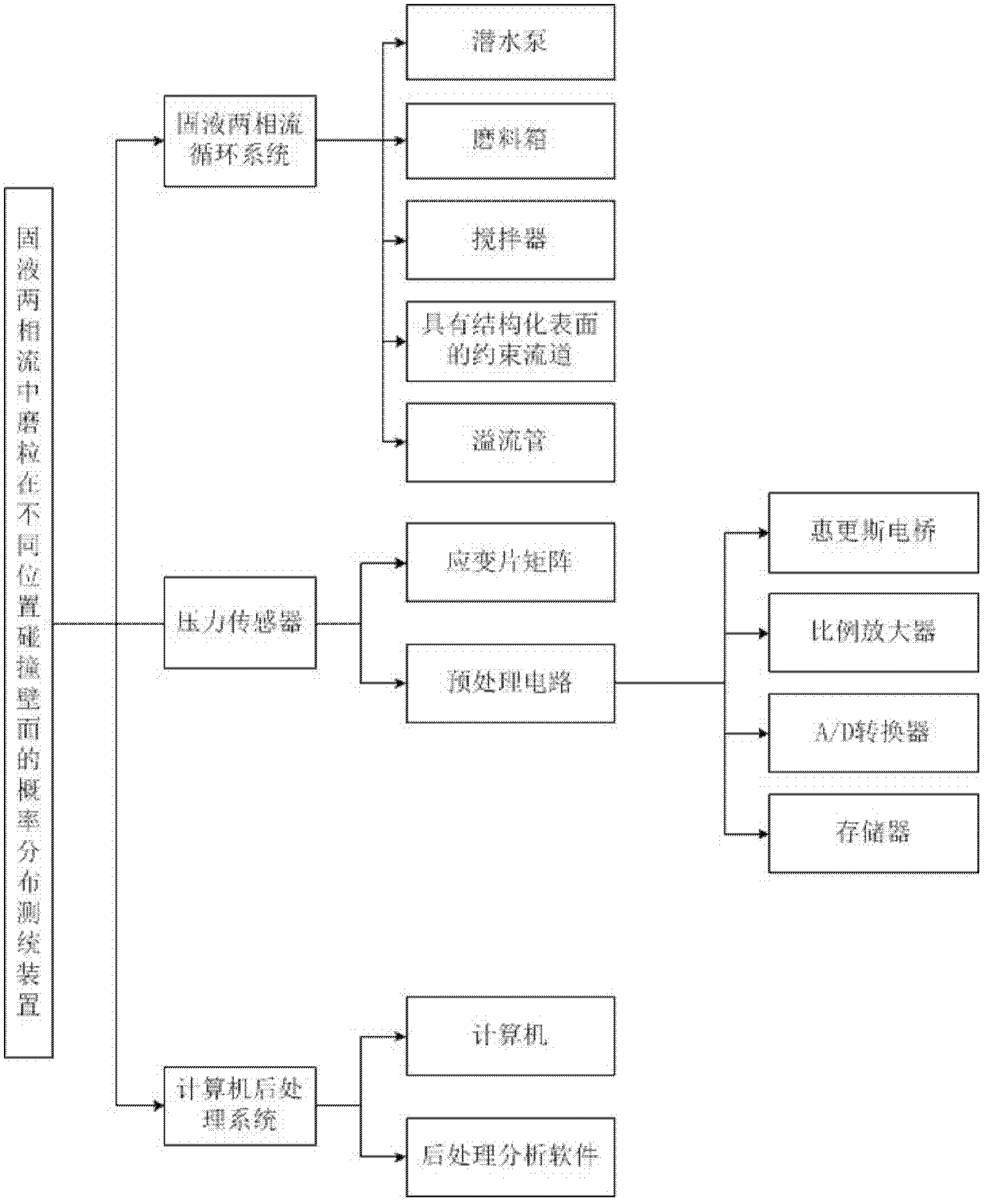

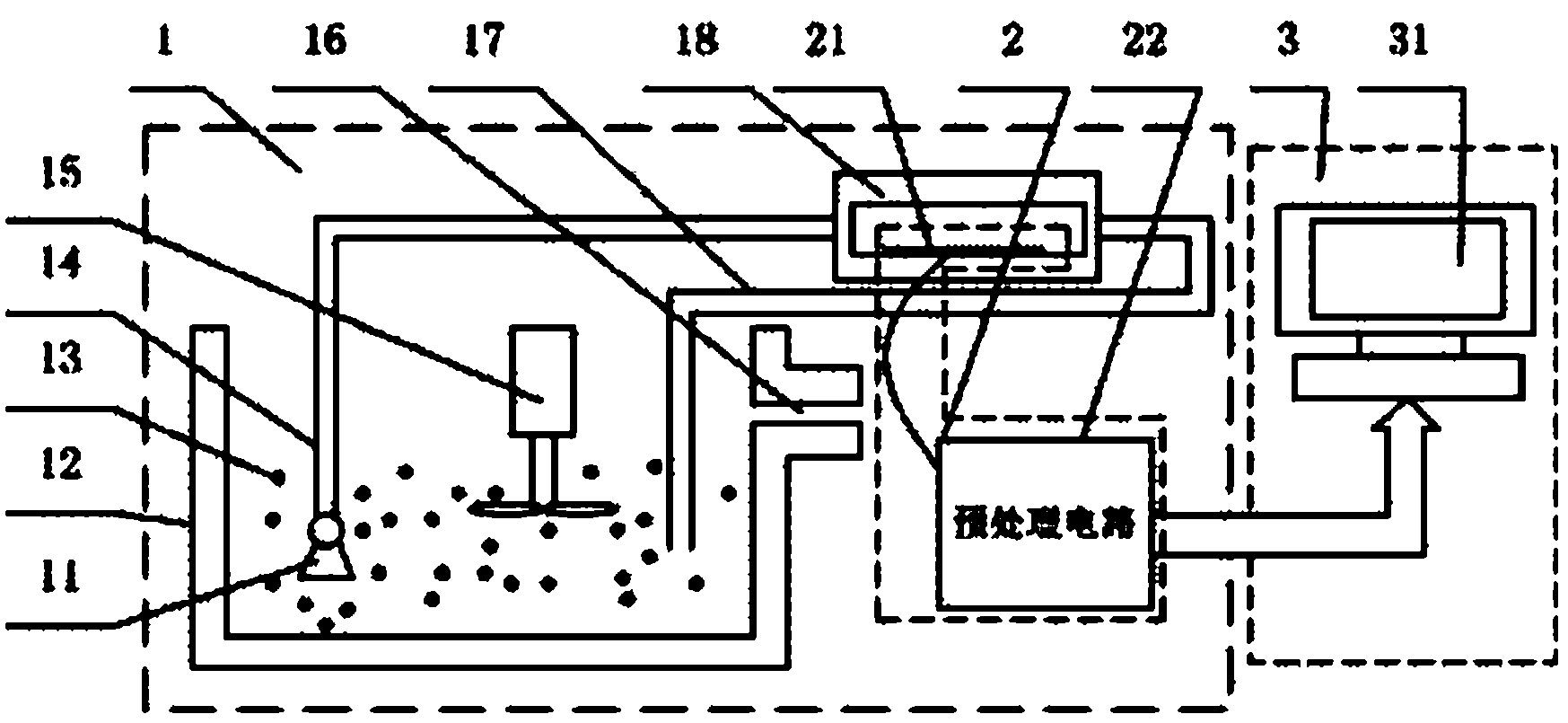

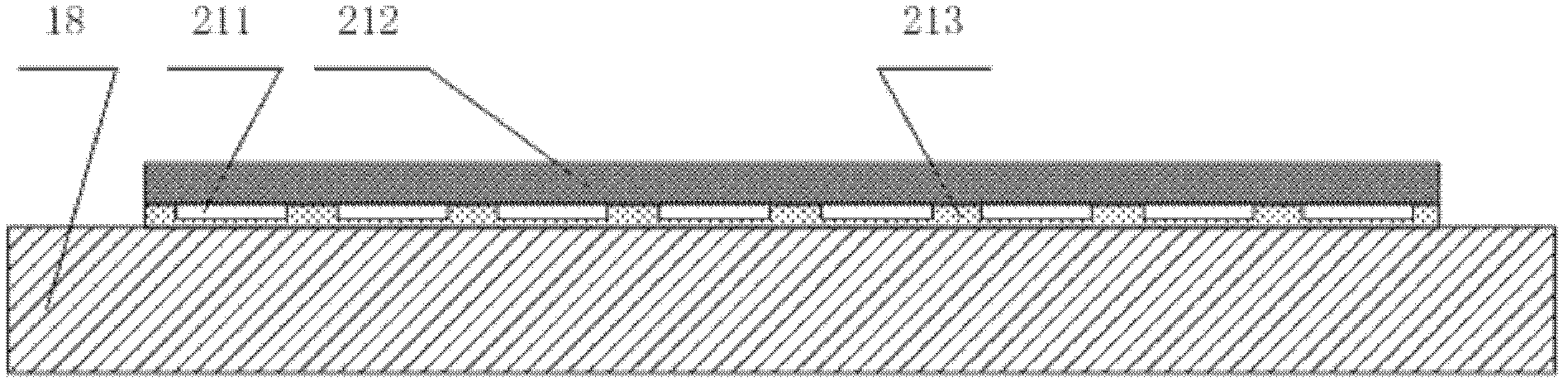

[0021] refer to Figure 1 to Figure 5 , a probability distribution test device and method for abrasive grains colliding with a wall at different positions in a solid-liquid two-phase flow, comprising a solid-liquid two-phase flow circulation system 1, a pressure sensor 2 and a computer post-processing system 3, the solid-liquid two-phase The flow circulation system 1 comprises a submersible pump 11, an abrasive tank 12, an agitator 15, an inlet hose 14, an outlet hose 17, a constrained flow channel 18 with a structured surface and an overflow pipe 16, and the pressure sensor 2 includes a strain gauge Matrix 21 and preprocessing circuit 22, the strain gauge matrix 21 is composed of a series of strain gauges 211 sealed and bonded to the lower surface of the metal sheet 212, and attached to the wall surface of the constrained flow channel 18 with a structured surface, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com