Automatic riveting equipment

An equipment, riveting technology, applied in metal processing equipment, assembly machines, manufacturing tools, etc., can solve problems such as damage to parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] specific implementation plan

[0040] These examples represent the best approach known to applicants for carrying out the invention, but they are not the best way to carry out the project.

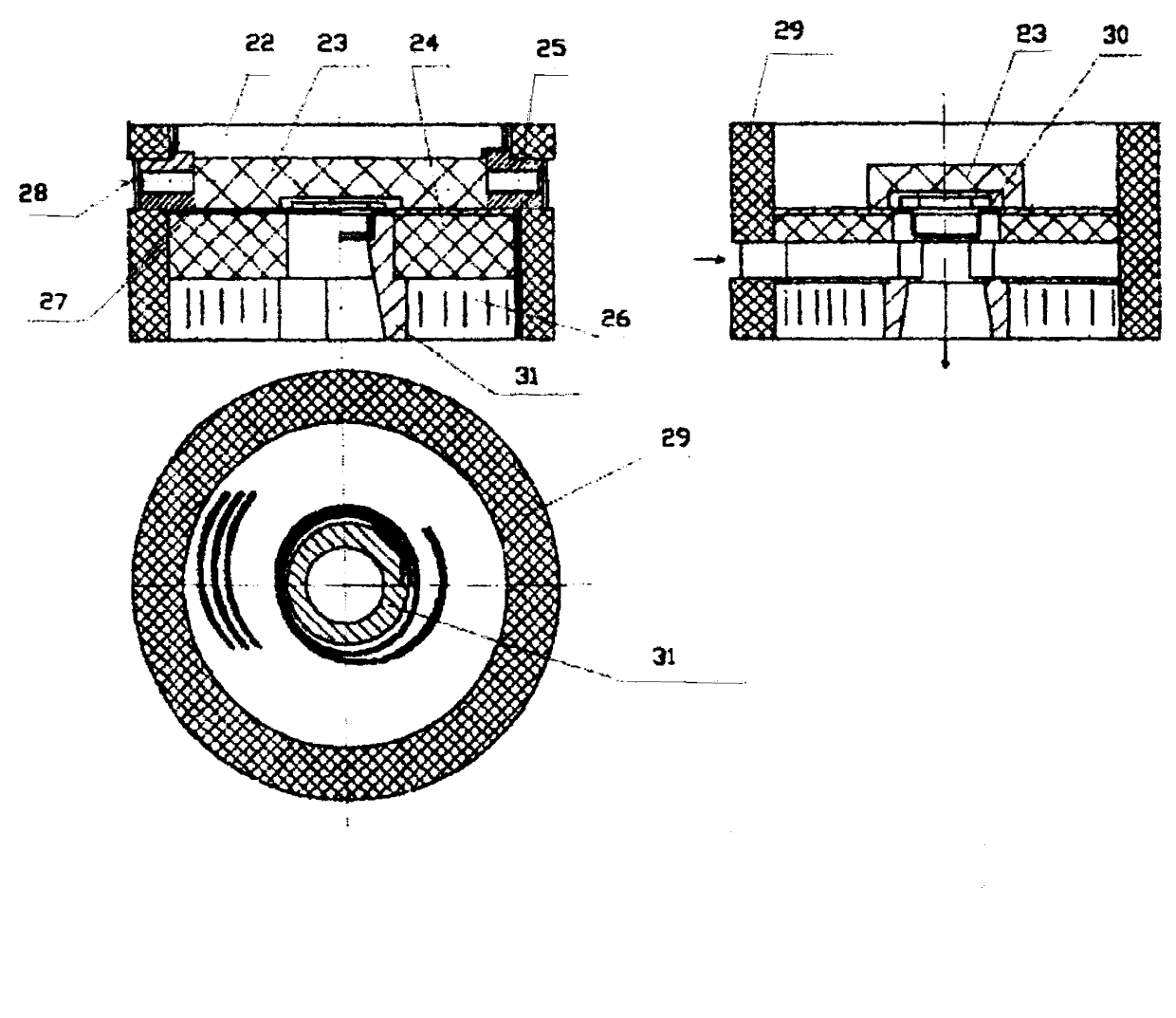

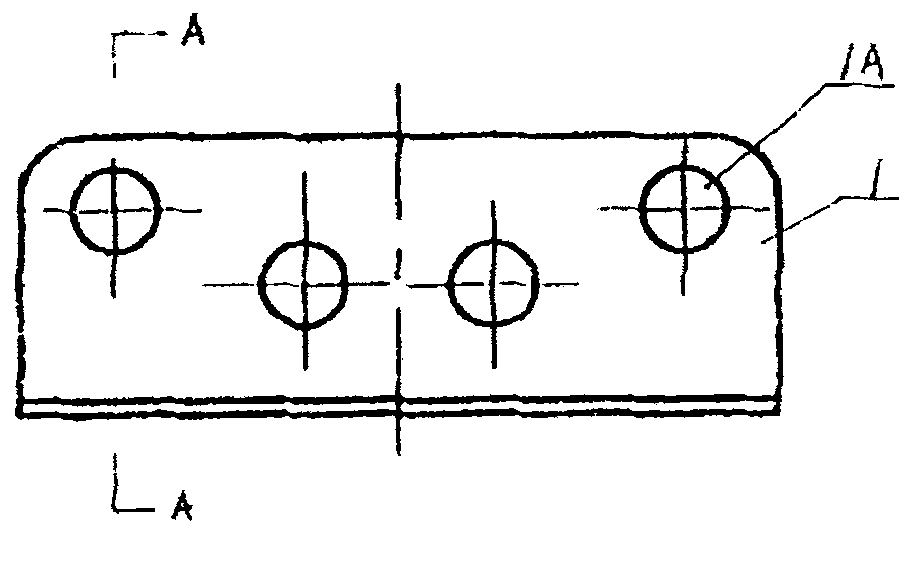

[0041]The bottom foot adopts the bottom corner of the standard shock-absorbing pad, which can be adjusted in height (±15mm), and is equipped with steel low foot components, 2 can be fixed on the ground, the bottom plate is made of 20mm thick steel plate, the surface is plated with hard chrome, 3X-Y The sliding table adopts the domestic advanced product Weiyuan sliding table, 4 the total stroke is 500mm, the tray is equipped with two rough positioning nylon blocks, 5 two positioning pins for fine positioning, three supporting columns, and two pneumatic clamps. 6. The bottom plate of the tray is made of high-quality aluminum plate, and the surface has been anodized. 7. The device is mainly composed of the rivet head bracket and the rivet head assembly. 6 The bracket is welded with a ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap