Suspension-type resistance spot welder connection cable real-time on-line monitoring method and device

A technology of resistance spot welding machine and connecting cables, which is applied in the direction of measuring devices, measuring electricity, and measuring electrical variables, etc., to achieve the effects of convenient installation, networked monitoring, and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

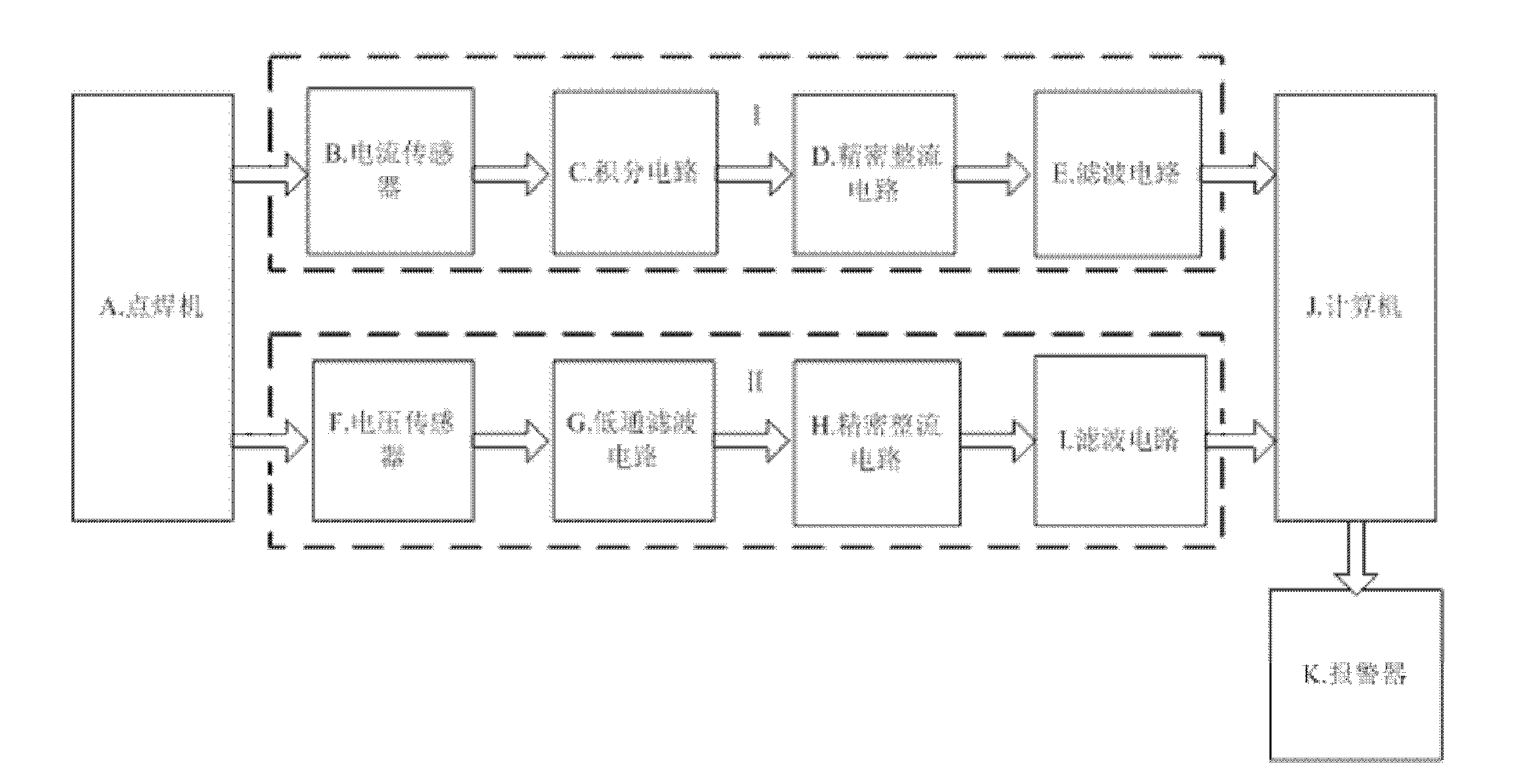

[0020] Attached below figure 1 Technical scheme of the present invention is described in further detail:

[0021] The working process of the real-time online monitoring device for the connection cable of the suspended resistance spot welding machine developed based on Ohm's law can be divided into four parts: welding current detection circuit I, welding voltage detection circuit II, computer system and alarm system.

[0022] Welding current detection circuit I: the induced electromotive force generated in current sensor B and the differential signal of the measured welding current (ie d(I (t) / dt) is directly proportional to the measured welding current and cannot directly reflect the measured welding current. The output signal of the sensor must be integrated. The integrating circuit C integrates the signal output by the current sensor B to restore the original waveform of the welding current. The current is directly proportional, and the phase is in phase with the welding c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com