Process for manufacturing sub-micrometer structure organic light emitting diode (OLED) by using porous alumina as template

A porous alumina technology, applied in the manufacture of semiconductor/solid-state devices, electrical components, electrical solid-state devices, etc., can solve the problem of difficulty in increasing the size of the mold, the poor effect of repeated use of the mold, and the inability to guarantee the embossing accuracy of hard abrasive tools and other issues to achieve the effect of improving light extraction efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail below in conjunction with accompanying drawing:

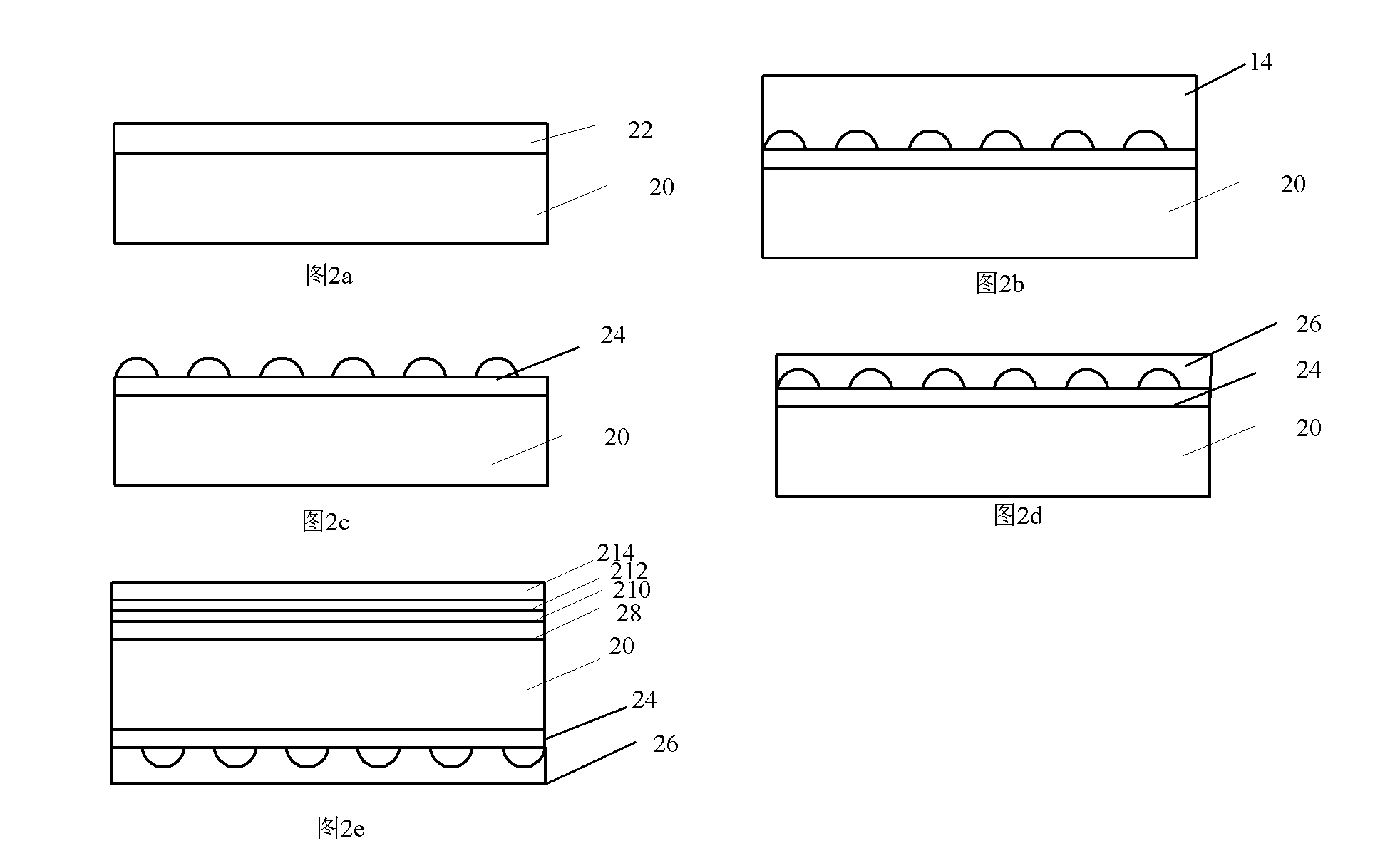

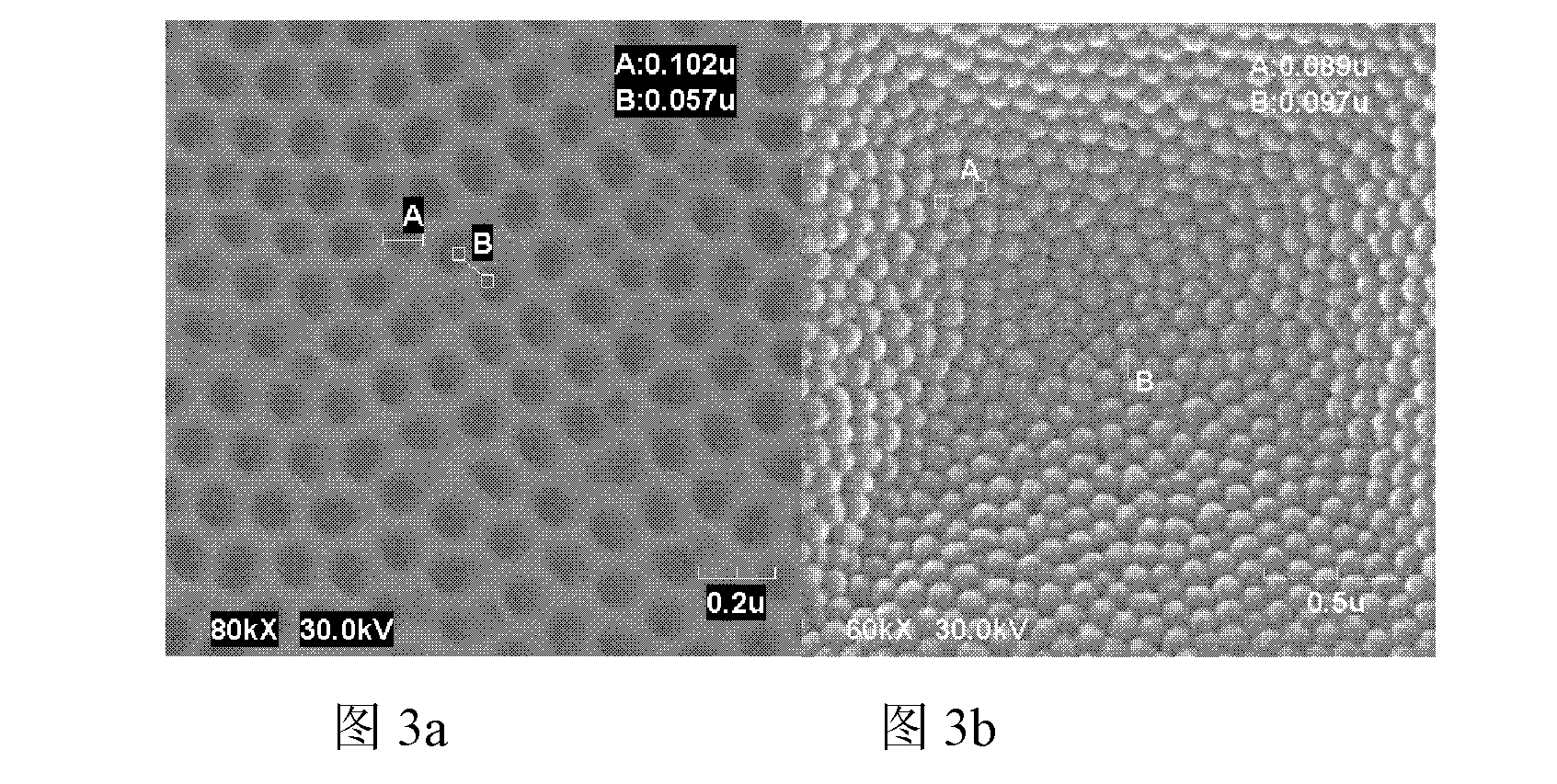

[0030] see Figure 1-4 , the process of preparing submicron-scale structures on OLEDs using porous alumina as a template in the form of ultraviolet nanoimprinting disclosed in this patent includes the following steps:

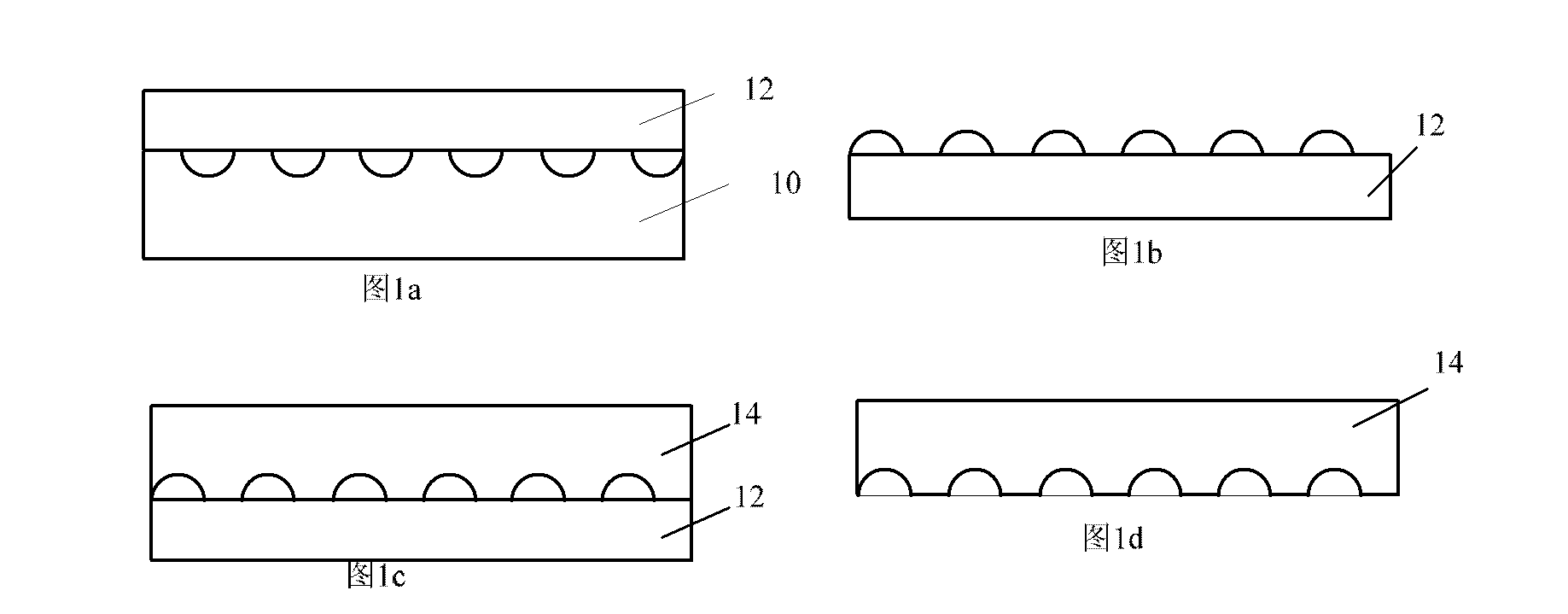

[0031] (1) if figure 1 As shown in a and 1b, the porous aluminum template is covered with PDMS, and the PDMS filler used is mixed with PDMS body and curing agent at a mass ratio of 10:1, and evenly poured on the surface of porous alumina, and then passed several times in a vacuum box. Vacuum again to remove the air bubbles in the contact surface and the solution; after the air bubbles completely disappear, put the template in an oven and bake it at 80 degrees Celsius for two hours, and after the PDMS is fully cured, peel off the PDMS from the porous alumina template;

[0032] (2) if figure 1 As shown in c and 1d, the PDMS filler is poured again on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com