Speed-sensor-less construction method for bearing-less asynchronous motor

A speed sensorless, asynchronous motor technology, applied in the control of generators, motor-generators, and electromechanical brakes, etc., can solve the problems of small local poles of neural networks, affecting control performance, and over-learning, and achieve strong generalization capabilities. and adaptive ability, easy engineering implementation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

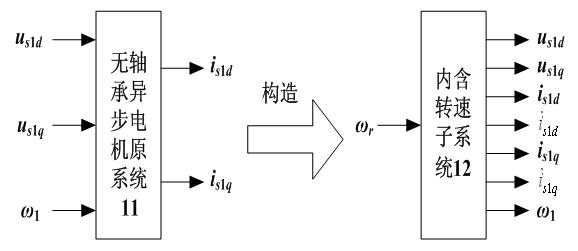

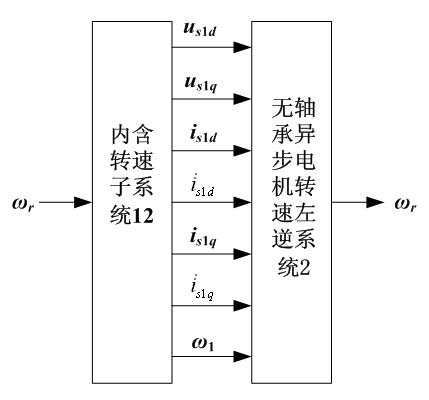

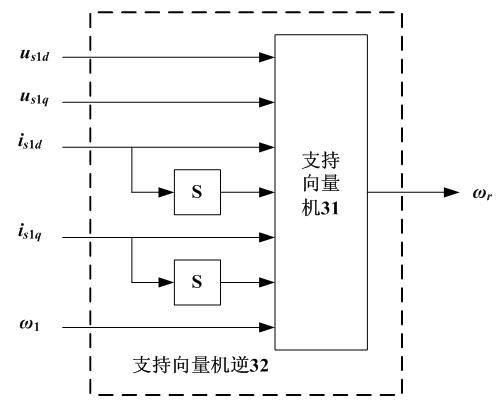

[0014] see Figure 4 , the present invention first establishes the mathematical model of the internal speed subsystem 12 based on the mathematical model of the original system 11 of the bearingless asynchronous motor. The variable constraint relationship determined by the model; then the inverse model containing the speed subsystem 12 is established, that is, the bearingless asynchronous motor speed left inverse system 2; and then the support vector machine 31 with 7 input nodes and 1 output node and 2 The differentiator S constitutes the SVM inverse 32 with 5 input nodes and 1 output node containing the rotational speed subsystem 12; and by adjusting the vector coefficients and thresholds of the SVM 31, the SVM inverse 32 realizes bearingless The function of the asynchronous motor speed left inversion system 2; finally, the support vector machine inverse 32 is connected in series with the original system 11 of the bearingless asynchronous motor to form a speed sensor, which c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com