Organic solid waste spiral charge pump

A technology of spiral feeding and organic solids, which is applied in the direction of solid waste removal, feeding devices, chemical/physical processes, etc., can solve the problems of low bulk density, oil and gas leakage, and hinder the implementation of organic solid waste pyrolysis process, etc., to achieve improvement Bulk density, reasonable structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

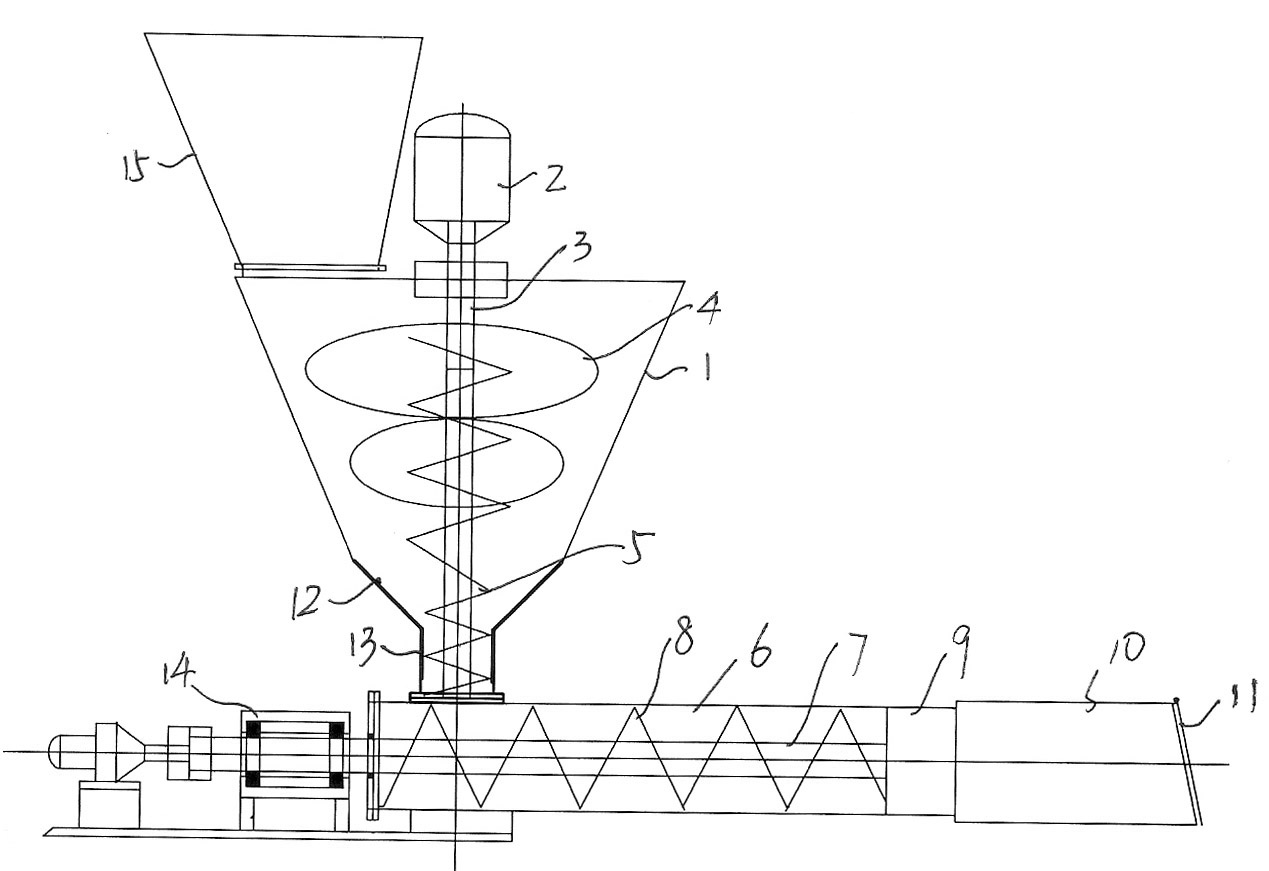

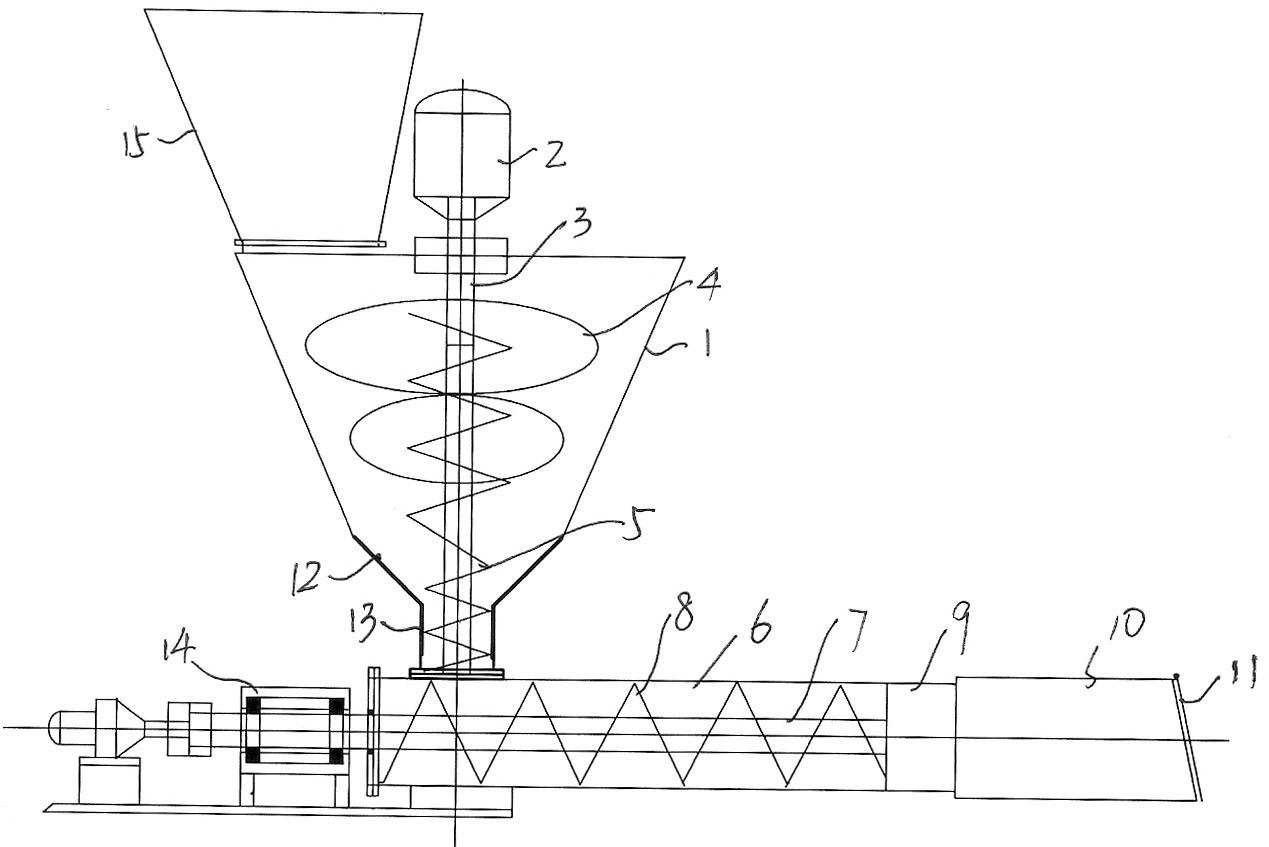

[0018] A screw feeding pump for organic solid waste, comprising a vertically installed primary screw feeder, the bottom of the primary screw feeder communicates with a horizontally installed secondary screw feeder, the primary screw feeder has a hopper 1, and a second screw feeder is arranged in the hopper The first screw 3 driven by a motor 2, the upper section of the first screw is provided with a flexible stirring fin 4, the lower section of the first screw is provided with a helical blade 5; It is the material propulsion area, and the cylindrical barrel of the first working area is equipped with a cantilevered second screw 7 driven by a second motor. The second screw is provided with screw blades 8, and the entire second screw is located in the first working area. The second working area 9 is a sealing area, and the cylinder diameter of the second working area is the same as that of the first working area, and the third working area is a diffusion area 10, and the diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Screw diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com