Electro-servo stretching pad

A technology of electric servo and stretching pads, which is applied in the field of electric servo stretching pads, can solve the problems of complicated maintenance, high energy consumption and large pollution of the CNC hydraulic pad system, and achieve the effects of suppressing wrinkling, reducing impact, and reducing electric energy The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

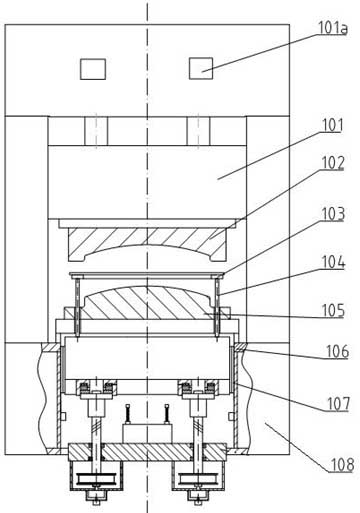

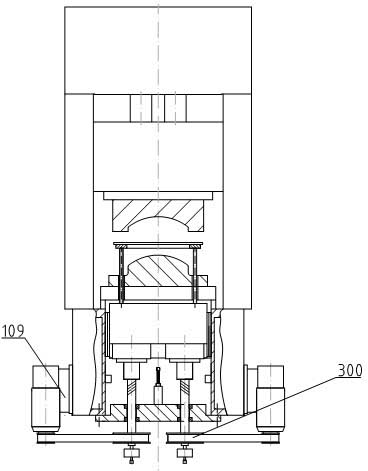

[0031] figure 1 , 2 Shown is the whole of a press equipped with an electric servo stretching pad in an embodiment of the present invention

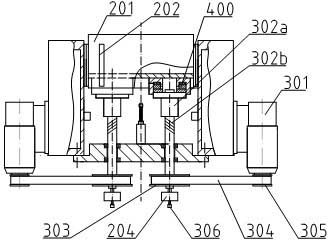

[0032] picture, image 3 Shown is a driving mechanism diagram of a large-tonnage single-crown servo tension pad in an embodiment of the present invention. As shown in the figure, the servo stretching pad includes a crown 201, a servo motor drive mechanism 300, a guide device, a limit device, a hydraulic buffer device, a load measuring device, a braking device, a servo drive and control system, a feedback device and an energy feedback storage device.

[0033] The servo tension pad in the embodiment of the present invention is a single crown, and four sets of servo drive mechanisms 300 are provided. The bracket 108 is installed on the bracket base 106 , and the lower side of the bracket 108 is connected with a servo motor 301 . A servo drive mechanism 300 is connected below the top crown 201, and the servo drive mechanism 300 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com