Processing method of diatomite wood-based fiberboard

A processing method and fiberboard technology, which can be used in wood processing appliances, household appliances, other household appliances, etc., can solve the problems of flammability application restrictions, pollution of the use environment, etc., to eliminate indoor odor, keep indoor clean, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

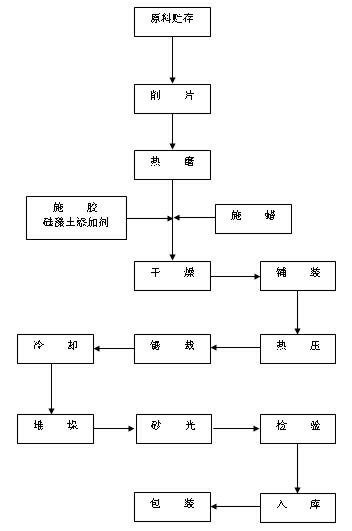

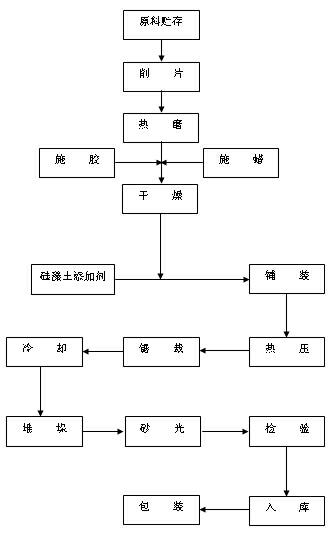

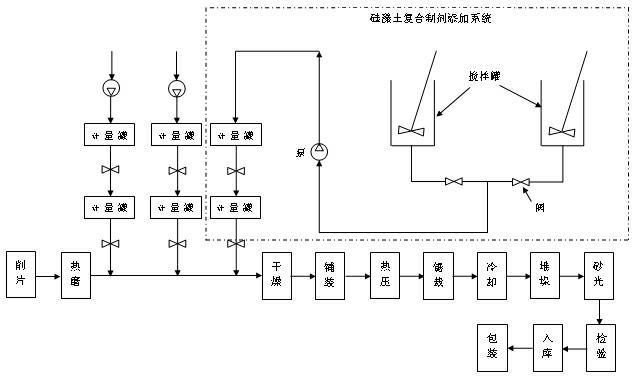

[0032] Such as image 3 as shown, Diatomite wood-based fiberboard through 1), slicing: the three leftovers such as branch wood produced in forestry are cut by a chipper into wood chips of qualified size, uniform, and even and smooth artwork; the specifications are: length 16-30mm, width 15mm -25mm, thickness 3-5mm;

[0033] 2) Thermal grinding: The wood chips that have been cooked at a high temperature of 165-175°C and high-pressured at 0.75-0.85MPa are separated into fibers by a thermal grinding machine, and the fibers are added with urea-formaldehyde resin adhesive, waterproofing agent, and silicon before entering the drying pipeline through the spray pipe. Algalite additive, sizing rate 200 -240 kg / m 3 , waterproofing agent (paraffin) is 6-8 kg / m 3 1. Diatomaceous earth is added at 1-30% by weight per ton of dry fiber.

[0034] 3) Drying: The fiber entering the drying pipe should have an inlet temperature below 175°C, an outlet temperature of 50-70°C, and a wind speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com