Beam tube production line for mine

A production line and mining technology, applied in the field of mine bundle tube production line, can solve problems such as restricting the production quality of mine bundle tubes, uneven coating, and uneven thickness, so as to avoid uneven wall thickness, uniform thickness, and pressure balanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0042] In the present invention, the raw material end is defined as the front end, and the finished product end is defined as the rear end.

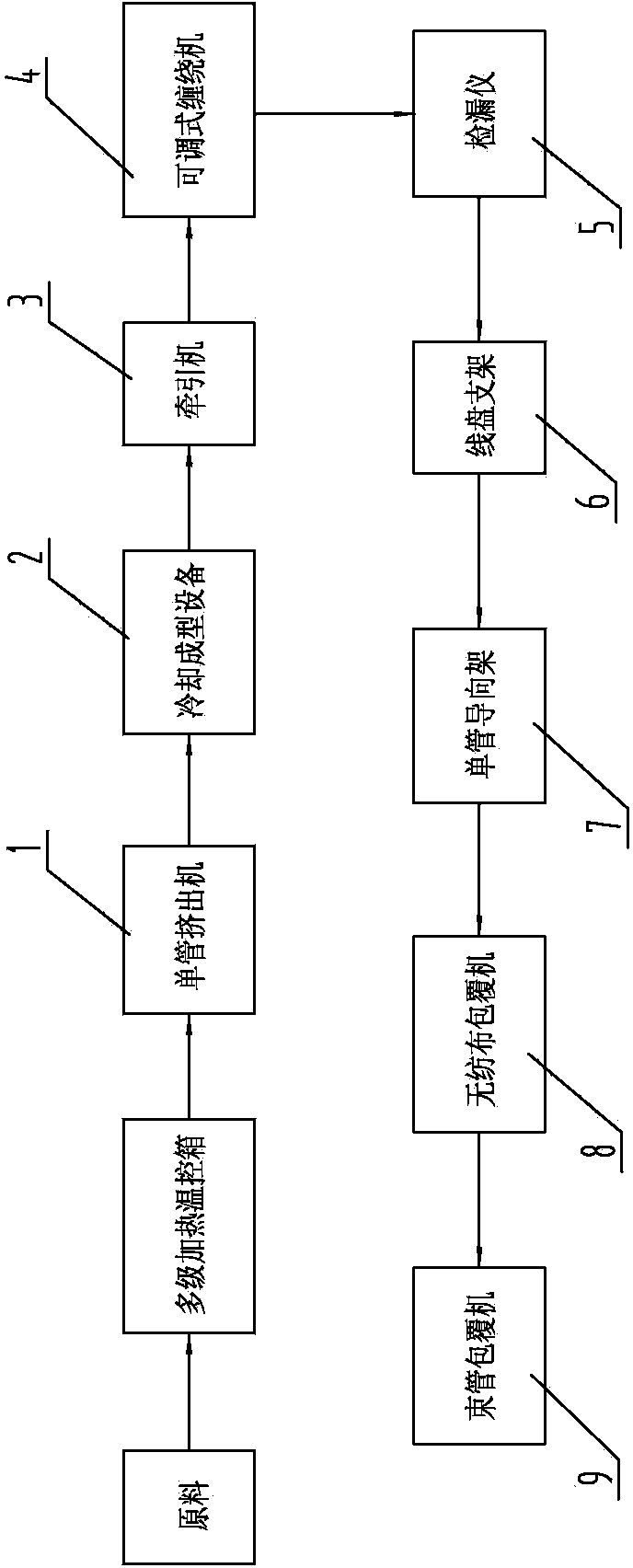

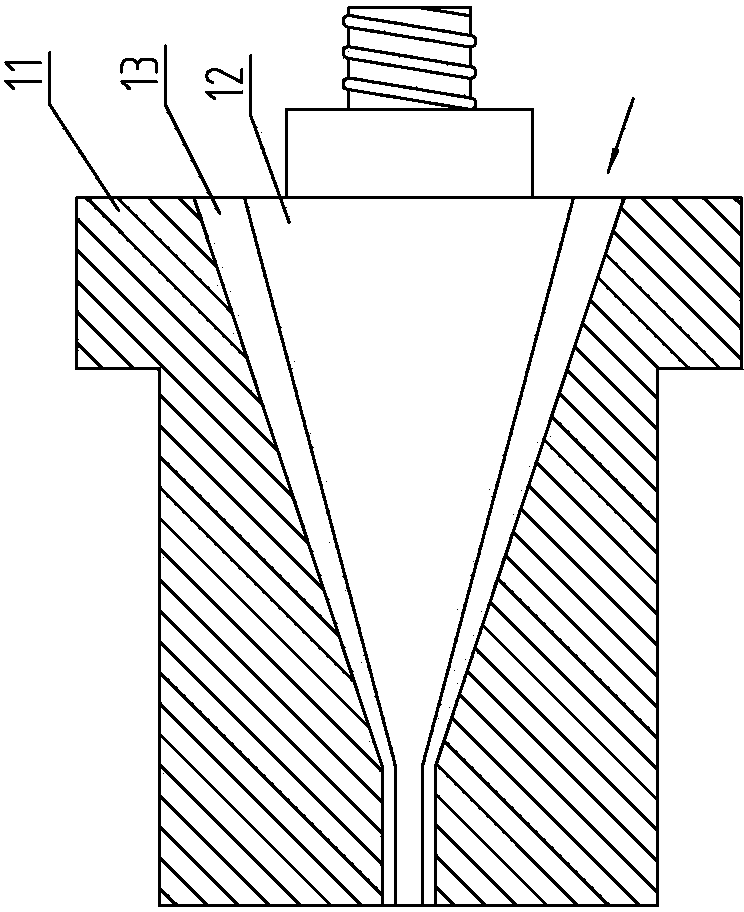

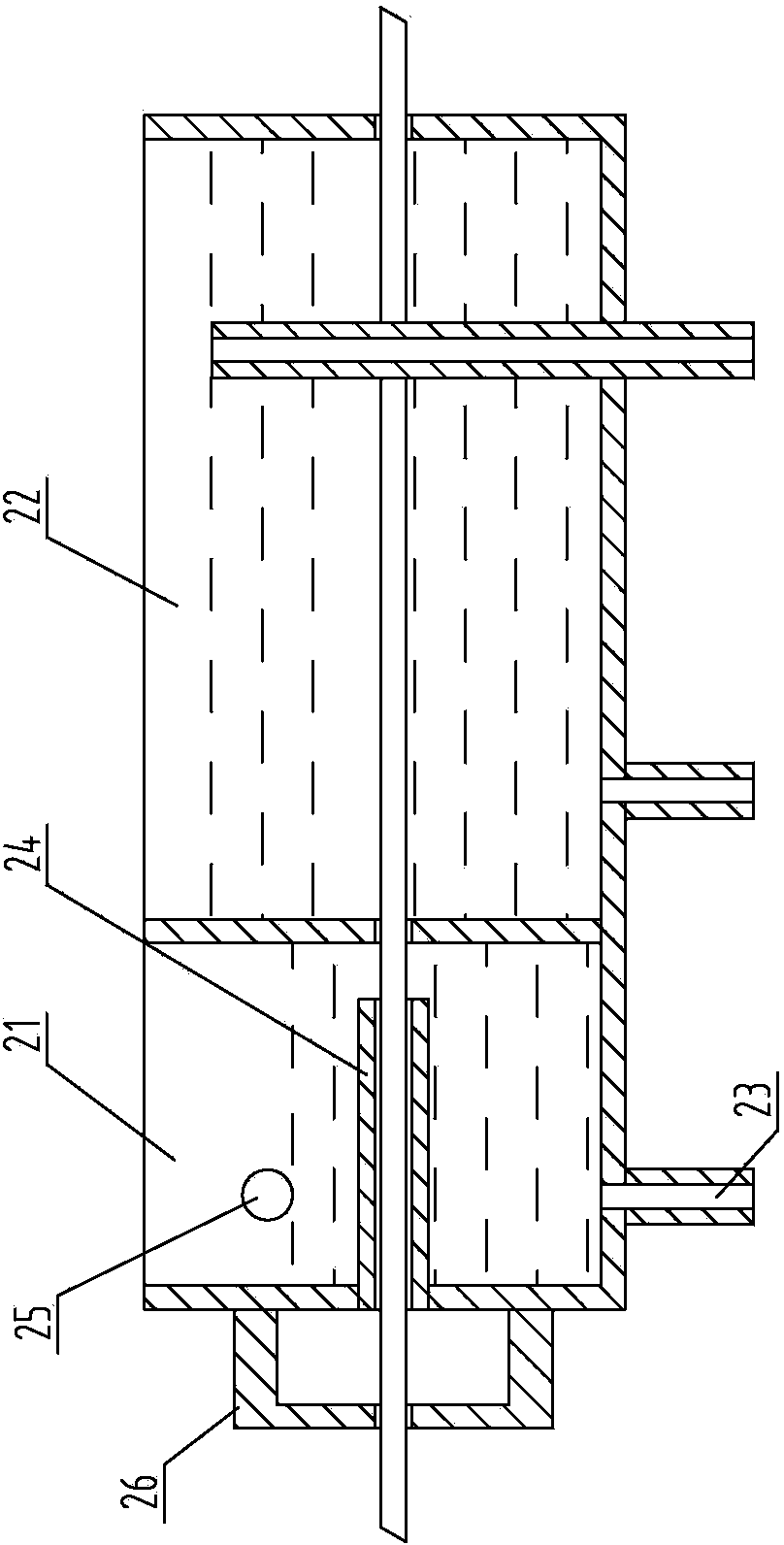

[0043] The present invention comprises two parts of single tube production equipment and bundle tube coating equipment, such as figure 1 , 2 As shown, the single-tube extruder 1 is located at the forefront of the production line, and the single-tube extruder 1 is provided with a mandrel 12. The mandrel 12 is conical from the discharge end to the feed end, and the mandrel 12 is equipped with a die 11. The first feeding chamber 13 is formed between the mandrel 12 and the mouth die 11. The axial space of the first feeding chamber 13 gradually decreases from the feeding end to the discharging end. The feeding direction is as follows: figure 2The directions of the middle arrows are consistent, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com