Production line for preparing welding seam glue

A production line and screw technology, applied in the field of welding seam adhesive preparation production line, can solve the problems of insufficient discharge pressure, low discharge rate, and increased cost, and achieve the effects of improved safety performance, reduced production cost, and convenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below through specific examples.

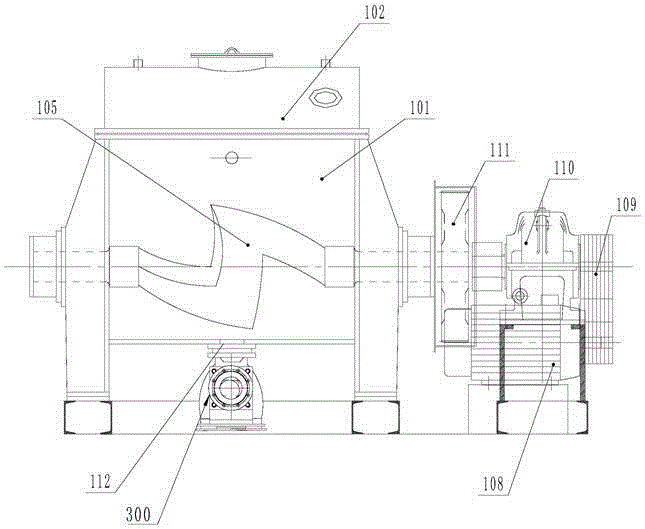

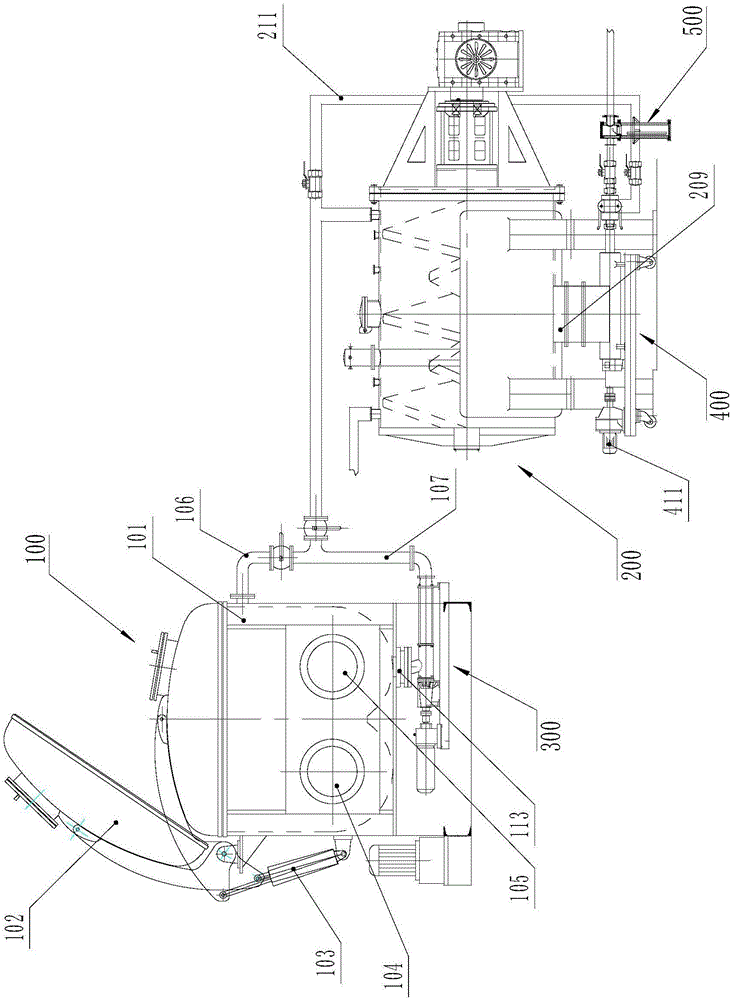

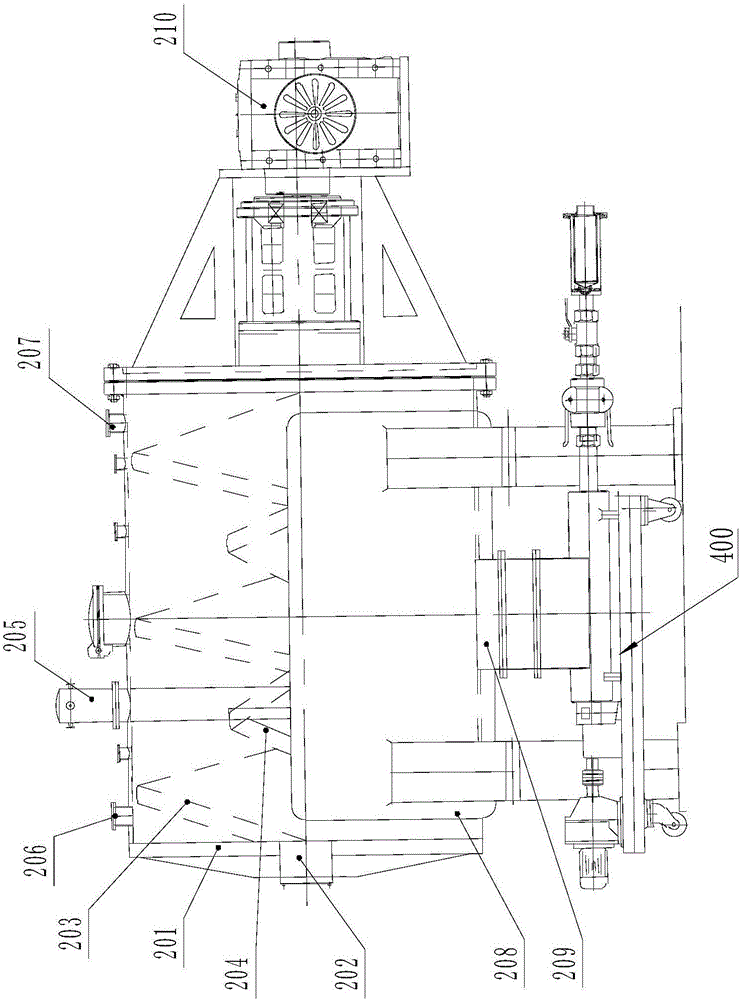

[0029] Such as figure 1 As shown, a weld glue preparation production line includes a kneader 100, a kneading screw discharge device 300, a mixing kettle 200, a mixing screw discharge device 400, a filter 500 and a barrel loading device, and the kneader 100 includes a kneader 100 Cylinder body 101 and cylinder head 102, cylinder head 102 is hinged on kneader 100 cylinder body 101 and is driven by overturning power device 103, and this overturning power device 103 adopts hydraulic cylinder, and hydraulic cylinder drives cylinder head 102 to turn over around hinge shaft, makes cylinder The cover 102 is opened or closed, and when opened, both powdery materials and liquid materials can be added into the cylinder body 101 of the kneader 100 from the top port of the cylinder body 101 of the kneader 100 .

[0030] Two kneading paddles driven by a kneading power device that cooperate wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com