Electric automobile and heat control system thereof

An electric vehicle, thermal control technology, applied in vehicle components, heating/cooling equipment, air handling equipment, etc., can solve the problems of multi-battery energy, low heating efficiency, poor cooling effect of heating components, etc., to achieve high heating efficiency, reduce The effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

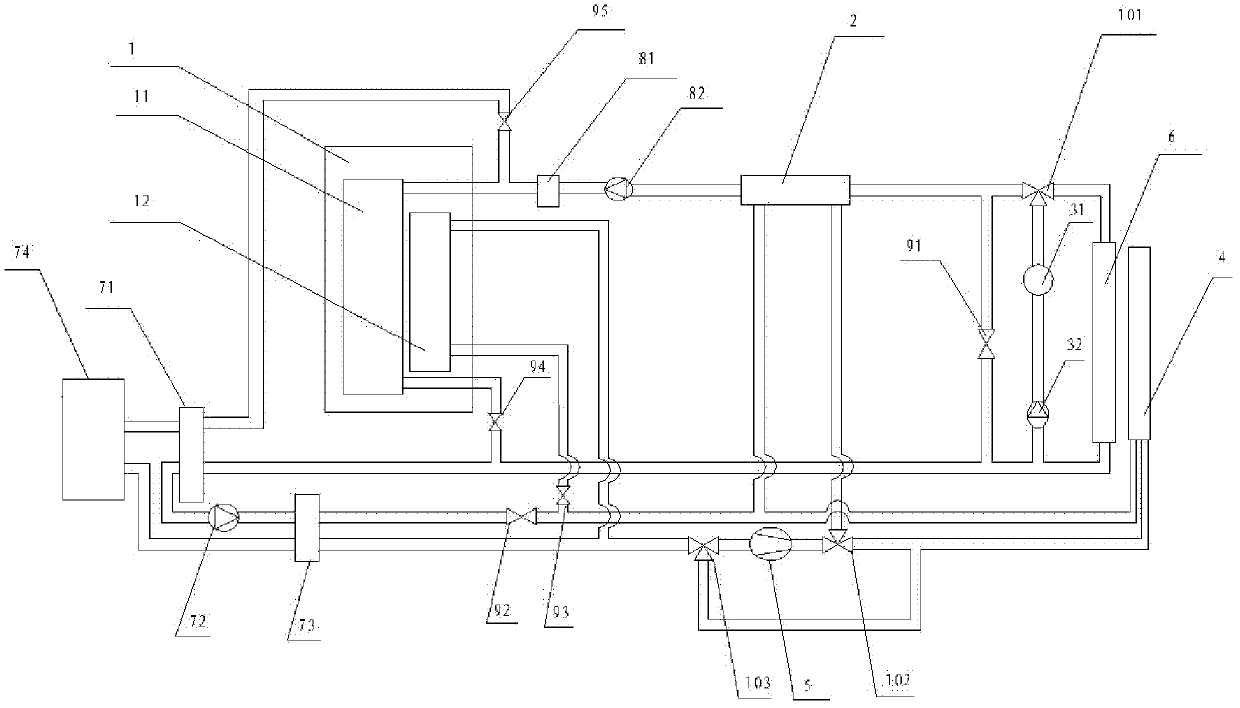

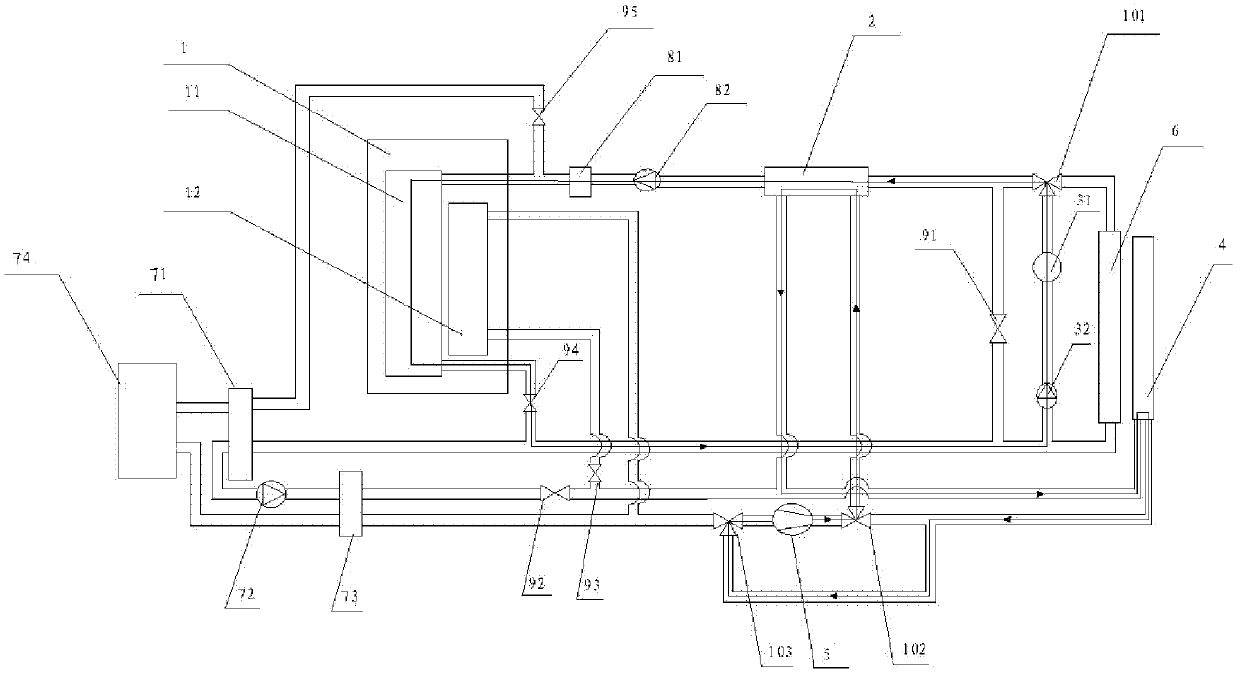

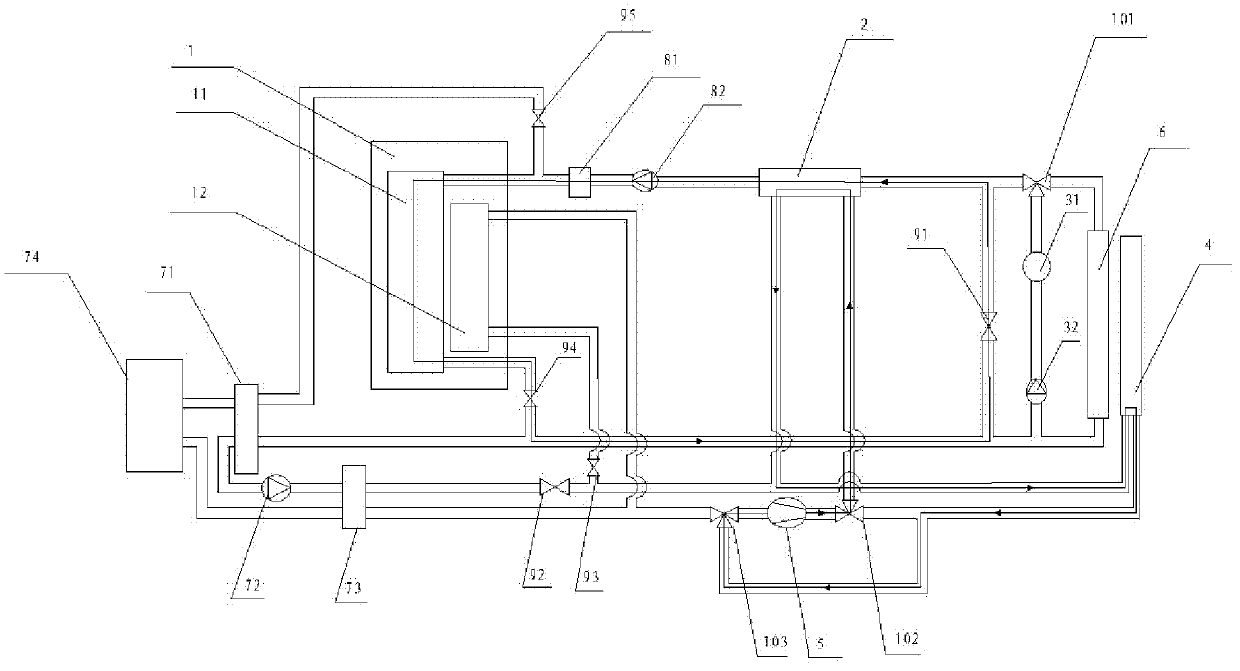

[0029] The thermal control system for an electric vehicle provided in Embodiment 1 of the present invention includes a first heat pump device, a second heat pump device, and a water-cooled condenser. Wherein, the first heat pump device includes a warm air core, a motor, and a first water pump connected by pipelines; the second heat pump device includes an electric compressor and an evaporative condenser connected by pipelines; the water-cooled condenser and the first heat pump device The warm air core in the heat pump is connected with the motor, so that the first heat pump device and the water-cooled condenser form a heating water circulation loop; the water-cooled condenser is connected with the electric compressor and the evaporative condenser in the second heat pump device, so that the second heat pump device A refrigerant circulation loop is formed with a water-cooled condenser.

[0030] When working, the first water pump is started, and the heat generated by the motor du...

Embodiment 2

[0033] The electric vehicle thermal control system provided by Embodiment 2 of the present invention, such as figure 1 As shown, the electric vehicle thermal control system includes a first heat pump device, a second heat pump device, and a water-cooled condenser 2 . The water-cooled condenser 2 is connected with the first heat pump device through pipelines to form a heating water circulation loop, and the water-cooled condenser 2 is connected with the second heat pump device through pipelines to form a refrigerant circulation loop.

[0034] Wherein, the first heat pump device includes a warm air core 11 connected in series, a water heating PTC 81, a third water pump 82, a motor 31 and the first water pump 32; the water-cooled condenser 2 is arranged between the third water pump 82 and the motor 31, and the first A two-way valve 494 is arranged between the water pump 32 and the warm air core 11. Further, the first heat pump device also includes a radiator 6 connected in paral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com